Preparation method and application of nano microcrystalline cellulose/dopamine composite film

A technology of nano-crystallite and cellulose, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of using and not being able to be used as a semi-permeable membrane, achieve good ion removal rate, and improve mechanical properties and separation performance, and the effect of promoting gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

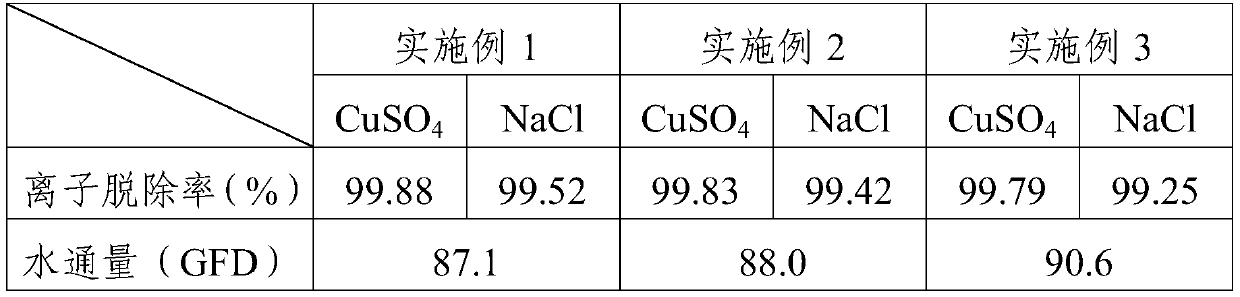

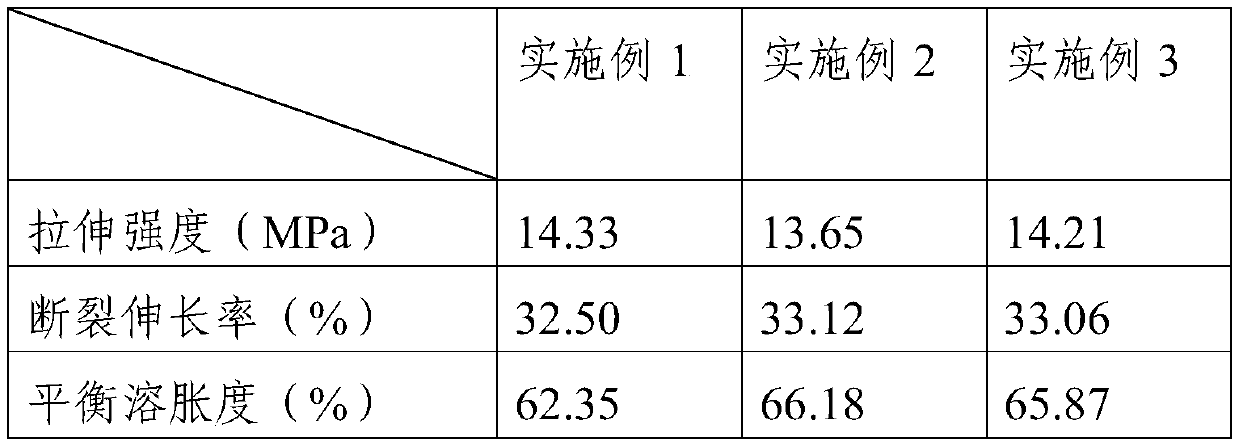

Examples

Embodiment 1

[0030] A preparation method of nano-microcrystalline cellulose / dopamine composite film, specifically as follows:

[0031] Corn bran was dried and crushed into powder, passed through a 200-mesh sieve, wrapped with nylon cloth, placed in a Soxhlet extractor, refluxed for 6 hours with a mixed solution of ether and n-hexane with a volume ratio of 3:1, and then filtered and dried (corn bran The mass ratio of the powder to the mixed solution of ether and n-hexane is 1:12), then added to the α-amylase solution with a mass concentration of 20%, adjusted the pH to 5-6 with citric acid, and heated to 45°C to hydrolyze 3.5 Centrifuge after h, wash the precipitate with water until it is neutral, add it to a NaOH solution with a mass concentration of 35%, and treat it ultrasonically at 90°C for 80 minutes, centrifuge, wash the precipitate with water until it is neutral, and dry it fully at 70°C to obtain prefabricated cellulose; prefabricated fiber Add the element into dimethyl sulfoxide, ...

Embodiment 2

[0033] A preparation method of nano-microcrystalline cellulose / dopamine composite film, specifically as follows:

[0034]Corn bran is dried and pulverized into powder, passed through a 200-mesh sieve, wrapped with nylon cloth, placed in a Soxhlet extractor, refluxed for 10 h with a mixed solution of ether and n-hexane with a volume ratio of 3:1, and then filtered and dried (corn bran The mass ratio of the powder to the mixed solution of ether and n-hexane is 1:15), and then added to the α-amylase solution with a mass concentration of 25%, adjusted the pH to 5-6 with citric acid, and heated to 50°C for 4 hours for hydrolysis After centrifugation, the precipitate was washed to neutrality and then added to a NaOH solution with a mass concentration of 35% for 75 minutes of ultrasonic treatment at 90°C, centrifuged, the precipitate was washed to neutrality and then fully dried at 80°C to obtain prefabricated cellulose; the prefabricated cellulose Add it into dimethyl sulfoxide, sti...

Embodiment 3

[0036] A preparation method of nano-microcrystalline cellulose / dopamine composite film, specifically as follows:

[0037] Corn bran is dried and pulverized into powder, passed through a 200-mesh sieve, wrapped with nylon cloth, placed in a Soxhlet extractor, refluxed for 10 h with a mixed solution of ether and n-hexane with a volume ratio of 3:1, and then filtered and dried (corn bran The mass ratio of the powder to the mixed solution of ether and n-hexane is 1:8), then added to the α-amylase solution with a mass concentration of 15%, adjusted the pH to 5-6 with citric acid, and heated to 42°C for 3 hours for hydrolysis After centrifugation, the precipitate was washed to neutrality and then added to a NaOH solution with a mass concentration of 40% for 80 min at 90°C, centrifuged, the precipitate was washed to neutrality and then fully dried at 65°C to obtain prefabricated cellulose; the prefabricated cellulose Add to dimethyl sulfoxide, stir at 400r / min to raise the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com