Method for synthesizing ZSM-5 zeolite orderly accumulated by nanometer crystallite

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of not many nano zeolites, achieve easy separation and recovery, and high yield , the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

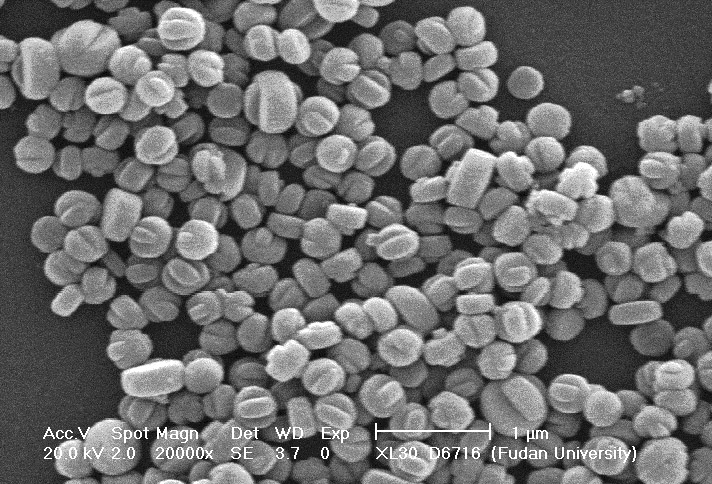

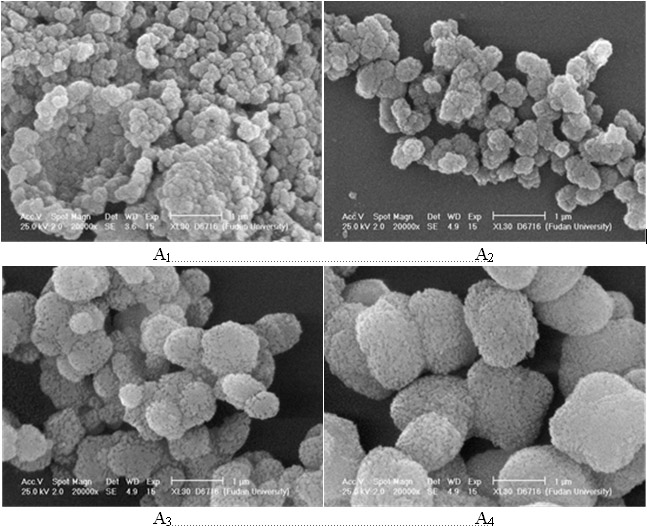

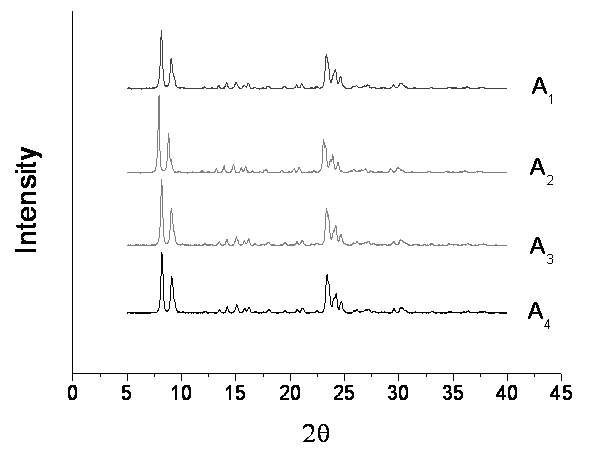

Embodiment 1

[0034] Add NaOH 1.1g, silica sol (SiO 2 40wt%) 11.3g and H 2 O 35.4g was made into A solution, and KF·2H was added 2 O 2.1g and H 2 O 8.0g is made into B solution, add TPABr 7.4g and H 2 O 12.0g to make C solution, add Al 2 (SO 4 ) 3 18H 2 O1.2g, H 2 O 27.9g and Na 2 SO 4 1.3g was formulated as D solution. Slowly add D to A with stirring, then B and C, and stir for 15 minutes. Then, add 5g of 5wt% 100nmS1 seed crystals, stir and age for 4 hours, and put it into a high-pressure stainless steel reactor containing a polytetrafluoroethylene liner for crystallization at 160-180°C for 20-30h. After the sample was cooled, it was washed with deionized water until neutral, dried at 100°C for 4 hours, and then heated to 550°C for 5 hours to remove the templating agent and roasted to obtain sample A. 1 .

Embodiment 2-4

[0036] Adopt the method consistent with embodiment 1, change seed crystal size, add respectively 200nm, 400nm, 600nm seed crystal, obtain A 2 、A 3 、A 4 .

Embodiment 5-8

[0038] Using the same method as in Example 1, just add 0.3g hexadecyltrimethylammonium bromide at the same time as the seed crystal, and add 100nm, 200nm, 400nm, 600nm seed crystals to obtain sample B respectively 1 , B 2 , B 3 , B 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com