Composition for glass, nano microcrystalline glass and preparation method and application thereof

A technology of nano-crystallite and glass-ceramic, which is applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc. It can solve the problems of poor light transmittance and stress layer depth of glass-ceramic, and achieve good light transmittance, Good resistance to falling and meeting the performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

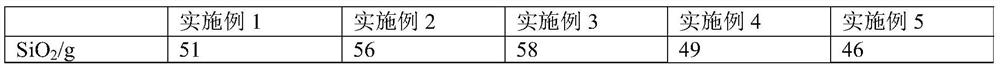

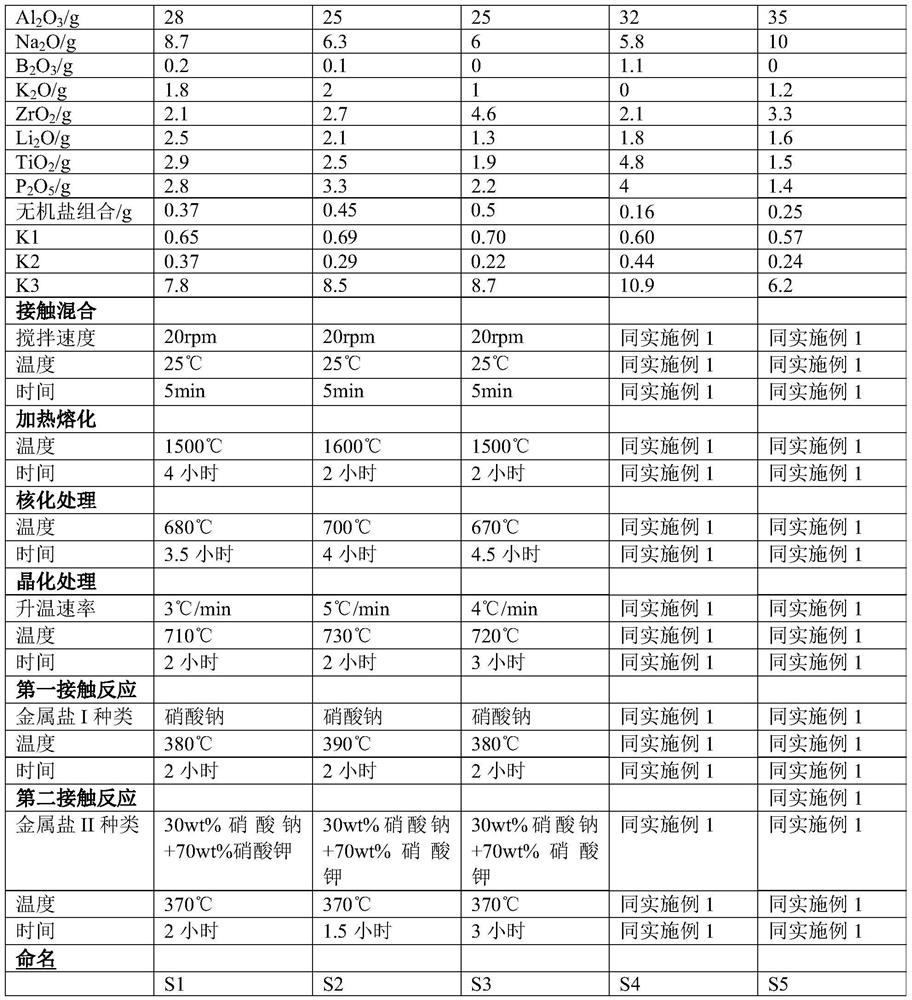

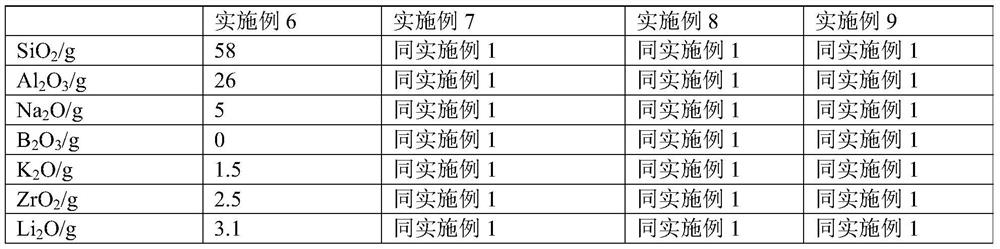

[0081] This example is used to illustrate that the composition for glass according to the present invention is prepared according to the formula and process parameters in Table 1, and the method as described below to prepare nano-glass ceramics.

[0082] The method for preparing nano glass ceramics comprises the following steps:

[0083] (1) Contact and mix the components in the composition for glass shown in Table 1 to obtain a mixed material, and heat and melt the mixed material to obtain a molten material;

[0084] Among them, the conditions of contact mixing are: the stirring speed is 20 rpm, the temperature is 25°C, and the time is 5 minutes; the conditions of heating and melting are: the temperature is 1500°C, and the time is 4 hours;

[0085] (2) performing nucleation treatment and crystallization treatment on the molten material prepared above in sequence to obtain a glass-ceramic precursor;

[0086] Among them, the conditions of the nucleation treatment are: the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com