Latex without separation and with sterilizing function as well as preparation method and application thereof

A latex and functional technology, applied in the field of functional latex preparation, can solve the problems of uneven agglomeration and dispersion, easy occurrence of bubbles, pinholes, color spots, adverse effects on the environment and human health, etc. Deodorizing function, the effect of widening the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

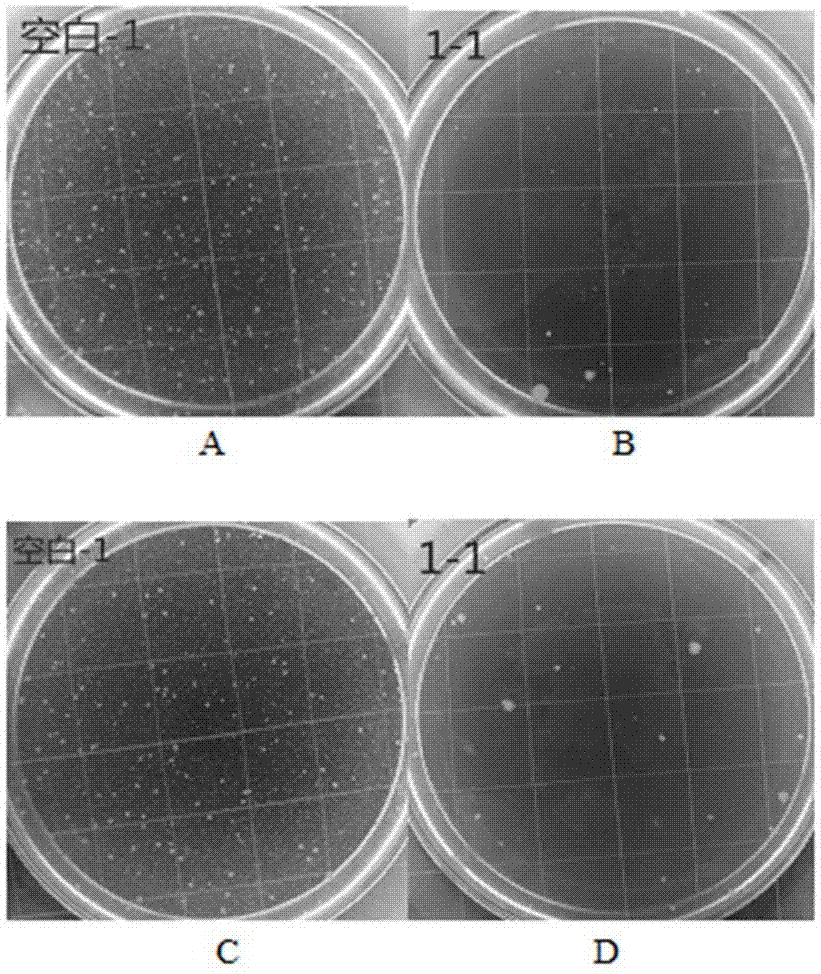

Embodiment 1

[0023] Dissolve zinc acetate, cerium nitrate, and polyvinylpyrrolidone in water at a molar ratio of 1:0.01:2.2 to prepare a 0.05M aqueous dispersion A; gradually add 10 ml of aqueous solution A to 100 ml of glycerol B; In a microwave oven, react at 150°C for 30 minutes, cool, centrifuge, and filter off the supernatant to obtain a nanocrystalline self-dispersion slurry with a crystallite size below 5nm; in latex liquid, 2% relative to natural latex The above-mentioned nano-mineral self-dispersion is injected into the above-mentioned nano-mineral self-dispersion according to the mass ratio, and the nano-emulsion mother liquor is obtained by mixing uniformly; the antibacterial latex condom is obtained by performing dipping, drying, demoulding, vulcanization, and post-treatment according to conventional production methods.

[0024] Table 1 is the metal ion precipitation detection result of the nano antibacterial latex product that is made according to the processing method of the p...

Embodiment 2

[0030] Dissolve copper acetate, cerium nitrate, and cyclodextrin in water at a molar ratio of 1:0.01:2.2 to prepare 0.05M aqueous dispersion A; gradually add 10 ml of aqueous solution A to 100 ml of polyethylene glycol B; put Put it into a microwave oven, react at 160°C for 30min, cool, centrifuge, and filter the supernatant to obtain a nanocrystalline self-dispersion slurry with a crystallite size below 5nm; % mass ratio Inject the above-mentioned nano-mineral self-dispersion, mix evenly, and obtain a brown nano-emulsion mother liquor; perform dipping molding, drying, demoulding, vulcanization, and post-treatment according to conventional production methods to prepare antibacterial gloves.

[0031] The metal ion precipitation detection result of the nano antibacterial latex product obtained by the processing method of this embodiment: Cu element is 0.435 mg / L, Ce element is 0.037 mg / L, all less than 1ppm, can be regarded as no precipitation. Its antibacterial effect is simila...

Embodiment 3

[0033] Dissolve zirconium acetate, neodymium nitrate, and lecithin in water at a molar ratio of 1:0.01:3 to prepare 0.05M aqueous dispersion A; gradually add 10 ml of aqueous solution A to 100 ml of glycerol B; put it in a microwave oven , react at 150°C for 30 minutes, cool, centrifuge, and filter off the supernatant to obtain a nanocrystalline self-dispersion slurry with a crystallite size below 5nm; in latex liquid, according to 3% mass relative to natural latex The above-mentioned nano-mineral self-dispersion is injected, mixed evenly, to obtain a nano-emulsion mother liquor; dipping molding, drying, demoulding, vulcanization, and post-treatment are carried out according to conventional production methods to prepare antibacterial pillows.

[0034] The metal ion precipitation test results of the nano antibacterial latex products prepared by the processing method of this embodiment are all less than 1ppm, which can be regarded as no precipitation. Its antibacterial effect is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com