A kind of cellulose fluorescent film and preparation method thereof

A cellulose membrane and cellulose technology, applied in the field of fluorescence detection, can solve problems such as practical application limitations, and achieve the effects of simple preparation method, increased removal effect, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

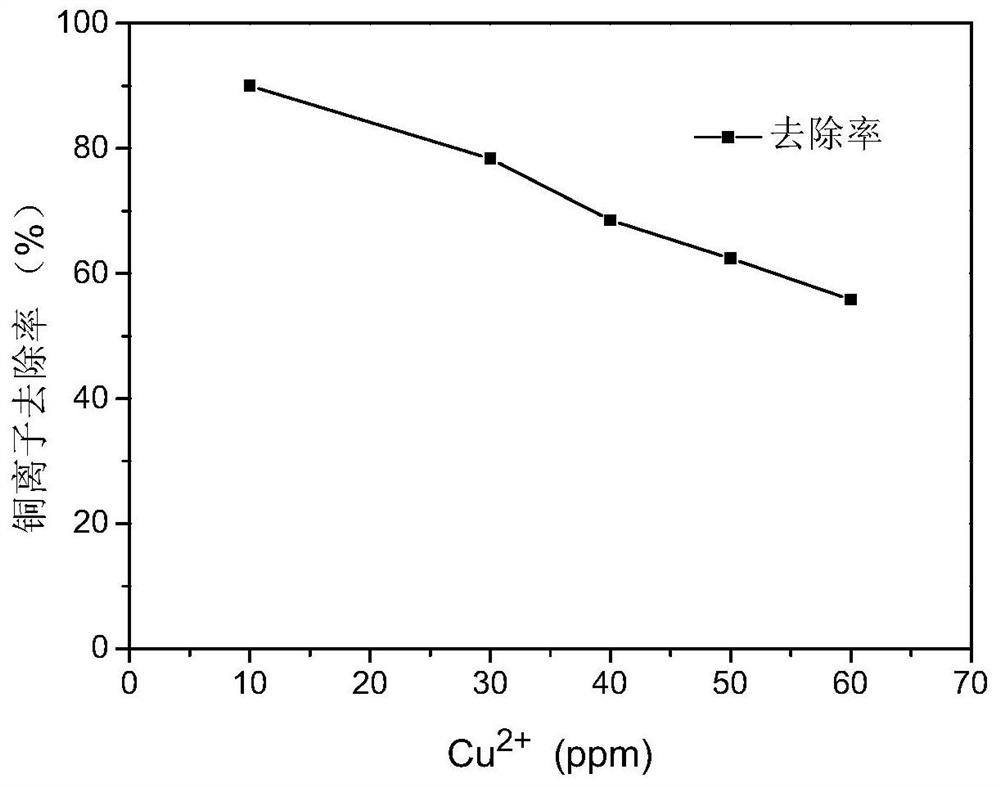

Embodiment 1

[0025] Weigh 10 g of natural cotton linter cellulose, 0.16 g of TEMPO reagent and 1 g of NaBr, and place in 600 mL of Na with a pH of 10.5 2 CO 3 / NaHCO 3 In the buffer solution, 8 mL of NaClO solution adjusted to pH 10 with HCl was added every 0.5 h, and the reaction time was started for 5 h when the NaClO solution was added for the first time. The reaction was carried out at room temperature with a stirring speed of 500 r / min. During the reaction, 0.5 mol / L NaOH was continuously added dropwise to keep the pH at 10-11. After the reaction was completed, excess ethanol was added to obtain a white precipitate, which was washed 3 times with absolute ethanol by a centrifuge, finally washed with acetone, and centrifuged. The solid product was added to 1% NaClO 2 In the solution, adjust the pH to about 4.8, continue to oxidize at room temperature for 48 hours, wash with deionized water, centrifuge, and freeze-dry, that is, the cellulose oxidized by TEMPO.

[0026] Weigh 2g of n...

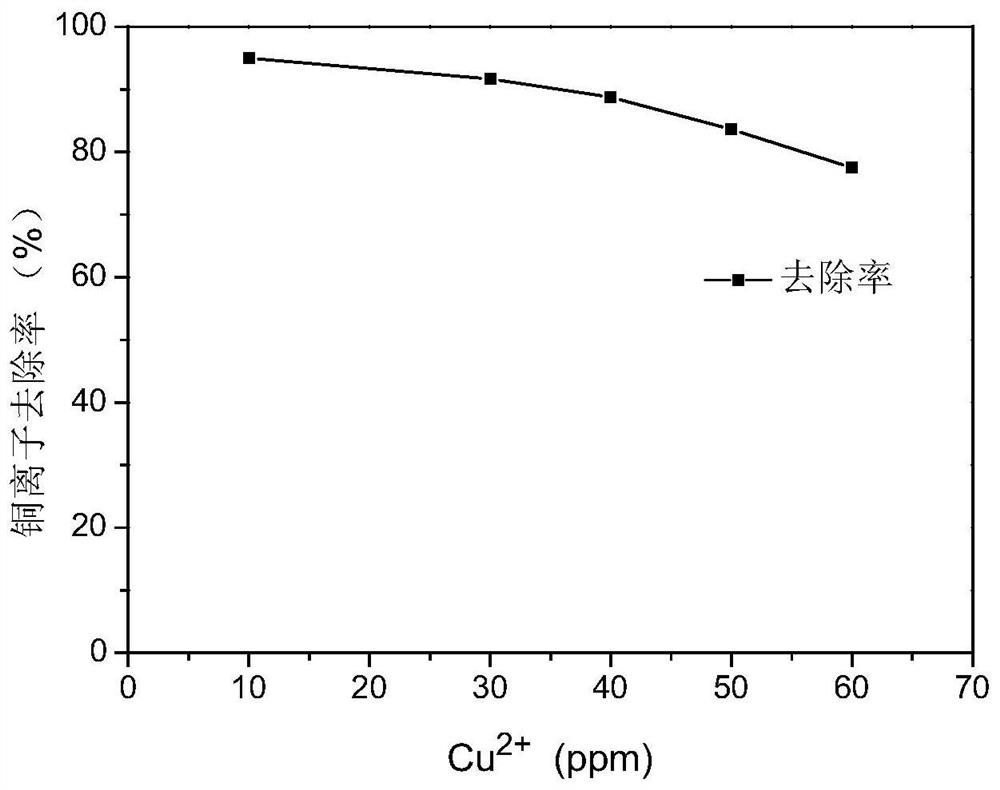

Embodiment 2

[0029] The TEMPO oxidized cellulose step is according to Example 1. Weigh 2.67g of natural cotton linter cellulose and 1.33g of TEMPO oxidized cellulose and mix them into a beaker. Other operating steps are according to Example 1.

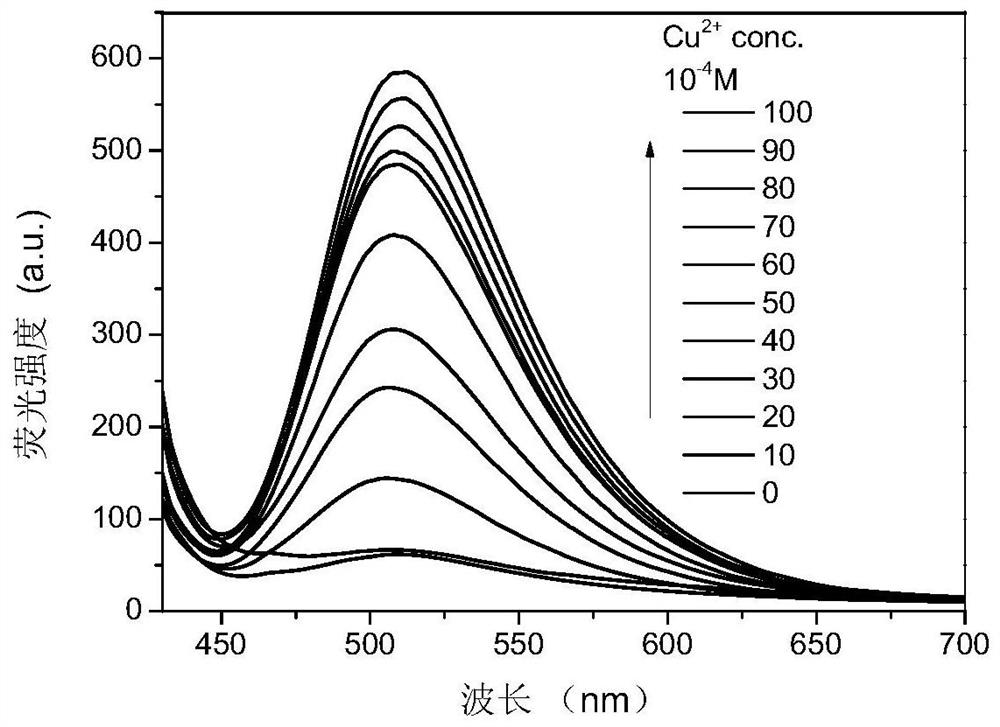

Embodiment 3

[0031]The step of TEMPO oxidizing cellulose and the step of preparing cellulose film are according to Example 1, prepare 0.5, 1, 1.5 mg / mg graphene oxide aqueous solution, soak the cellulose film for 24 hours respectively, and compare the effects of three kinds of graphene oxide concentrations on cellulose The influence of the film, under the premise of ensuring that the fluorescent effect is not affected and the loading efficiency of the fluorescent molecules is improved, a 1 mg / mL graphene oxide solution was selected to obtain a cellulose film loaded with graphene oxide, and other operating steps were as in Example 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com