Nano micro-crystal cubic boron nitride abrasive cloth and manufacture method thereof

A cubic boron nitride and nanocrystalline technology, which is used in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of high temperature resistance, coarse abrasive cloth, and non-sharpness, and achieve the effect of high firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

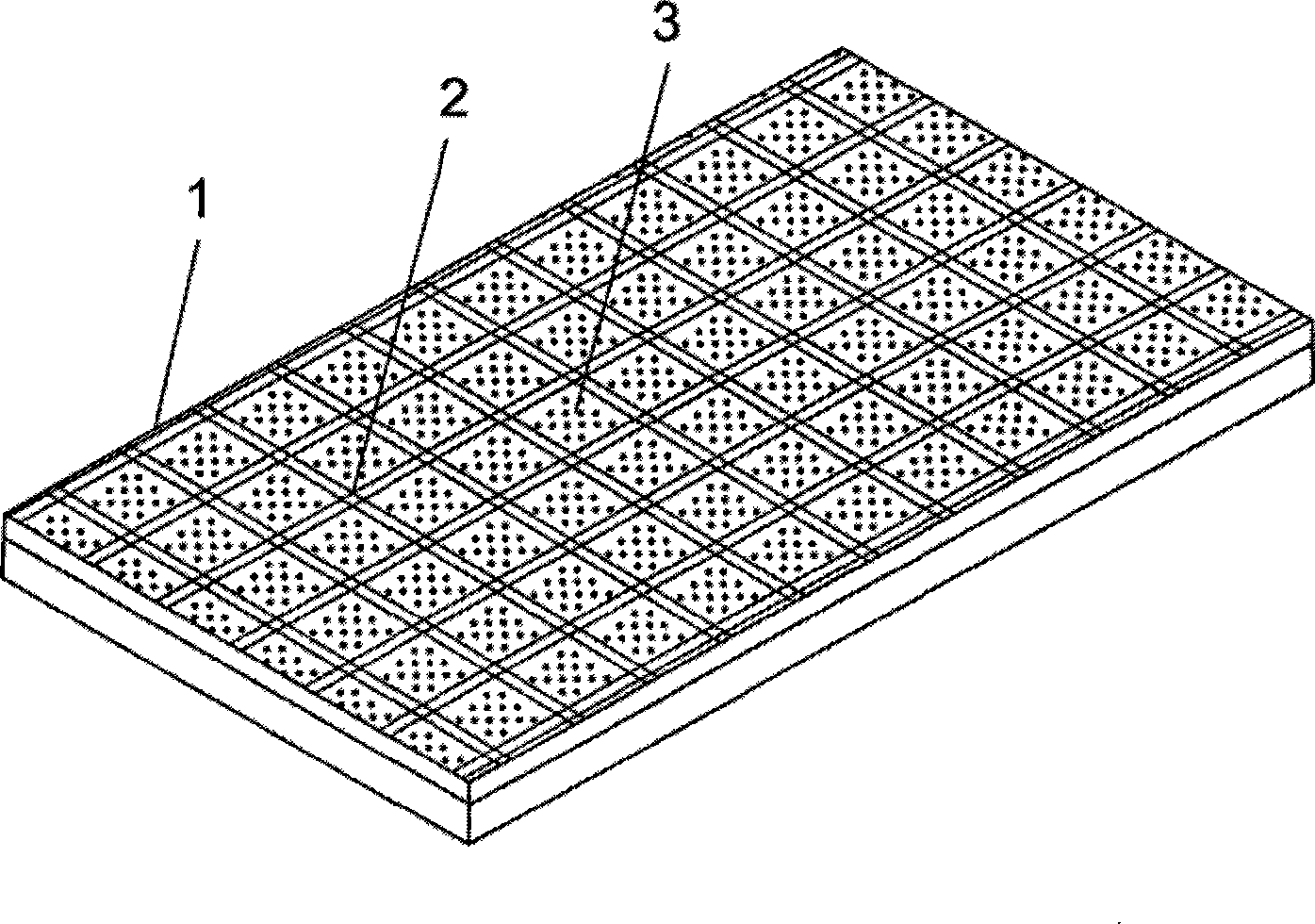

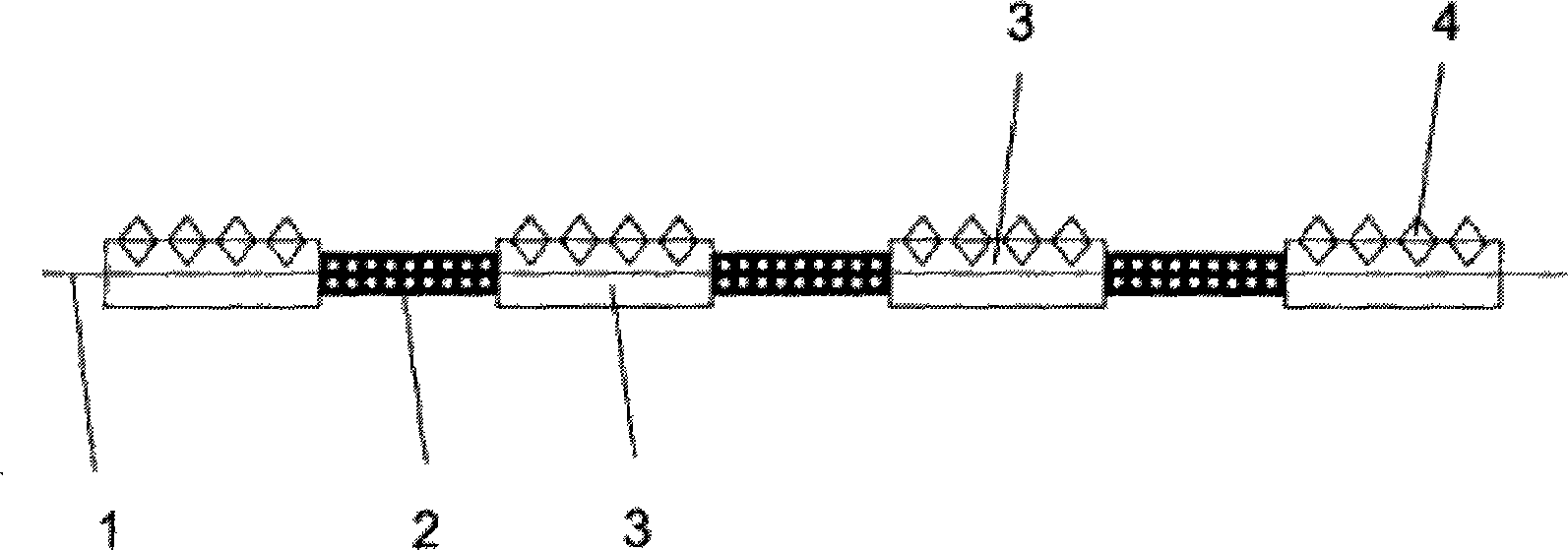

[0018] As shown in the figure, the nano-microcrystalline cubic boron nitride emery cloth of the present invention includes a substrate 1, and non-conductive material layers 2 corresponding to the upper and lower sides are arranged at intervals in the length direction of the substrate, so that the substrate is separated into substrates with conductive lines at intervals. A metal base layer 3 is attached to the conductive lines, and nanometer microcrystalline cubic boron nitride powder 4 is evenly distributed in the metal base layer. The substrate is abrasive cloth made of conductive wire mesh.

[0019] The method for manufacturing nano-microcrystalline cubic boron nitride emery cloth is as follows:

[0020] 1) Select a material with conductive properties to make the substrate of the emery cloth; cover the parts of the substrate that are not sanded on the upper and lower sides to form a regular grid-like network;

[0021] 2) Then evenly plant the nanocrystalline cubic boron nit...

Embodiment 2

[0025] As shown in the figure, the nano-microcrystalline cubic boron nitride emery cloth of the present invention includes a substrate 1, and non-conductive material layers 2 corresponding to the upper and lower sides are arranged at intervals in the length direction of the substrate, so that the substrate is separated into substrates with conductive lines at intervals. A metal base layer 3 is attached to the conductive lines, and nanometer microcrystalline cubic boron nitride powder 4 is evenly distributed in the metal base layer. The substrate is wire mesh or non-metal base cloth.

[0026] The method for manufacturing nano-microcrystalline cubic boron nitride emery cloth is as follows:

[0027] 1) Select a material with conductive properties to make the substrate of the emery cloth; cover the parts of the substrate that are not sanded on the upper and lower sides to form a regular grid-like network;

[0028] 2) Then evenly plant the nanocrystalline cubic boron nitride powde...

Embodiment 3

[0032] As shown in the figure, the nano-microcrystalline cubic boron nitride emery cloth of the present invention includes a substrate 1, and non-conductive material layers 2 corresponding to the upper and lower sides are arranged at intervals in the length direction of the substrate, so that the substrate is separated into substrates with conductive lines at intervals. A metal base layer 3 is attached to the conductive lines, and nanometer microcrystalline cubic boron nitride powder 4 is evenly distributed in the metal base layer. The matrix is in the shape of a regular lattice mesh.

[0033] The method for manufacturing nano-microcrystalline cubic boron nitride emery cloth is as follows:

[0034] 1) Select a material with conductive properties to make the substrate of the emery cloth; cover the parts of the substrate that are not sanded on the upper and lower sides to form a regular grid-like network;

[0035] 2) Then evenly plant the nanocrystalline cubic boron nitride p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com