Side-chain aryl conjugated organic light-emitting material and preparation method thereof

A luminescent material and aryl-based technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of poor film-forming properties, poor stability of organic luminescent materials, limited luminescent wavelength range, etc., and achieve good anti-oxidation crosslinking, High emission purity, improve the effect of anti-oxidative cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

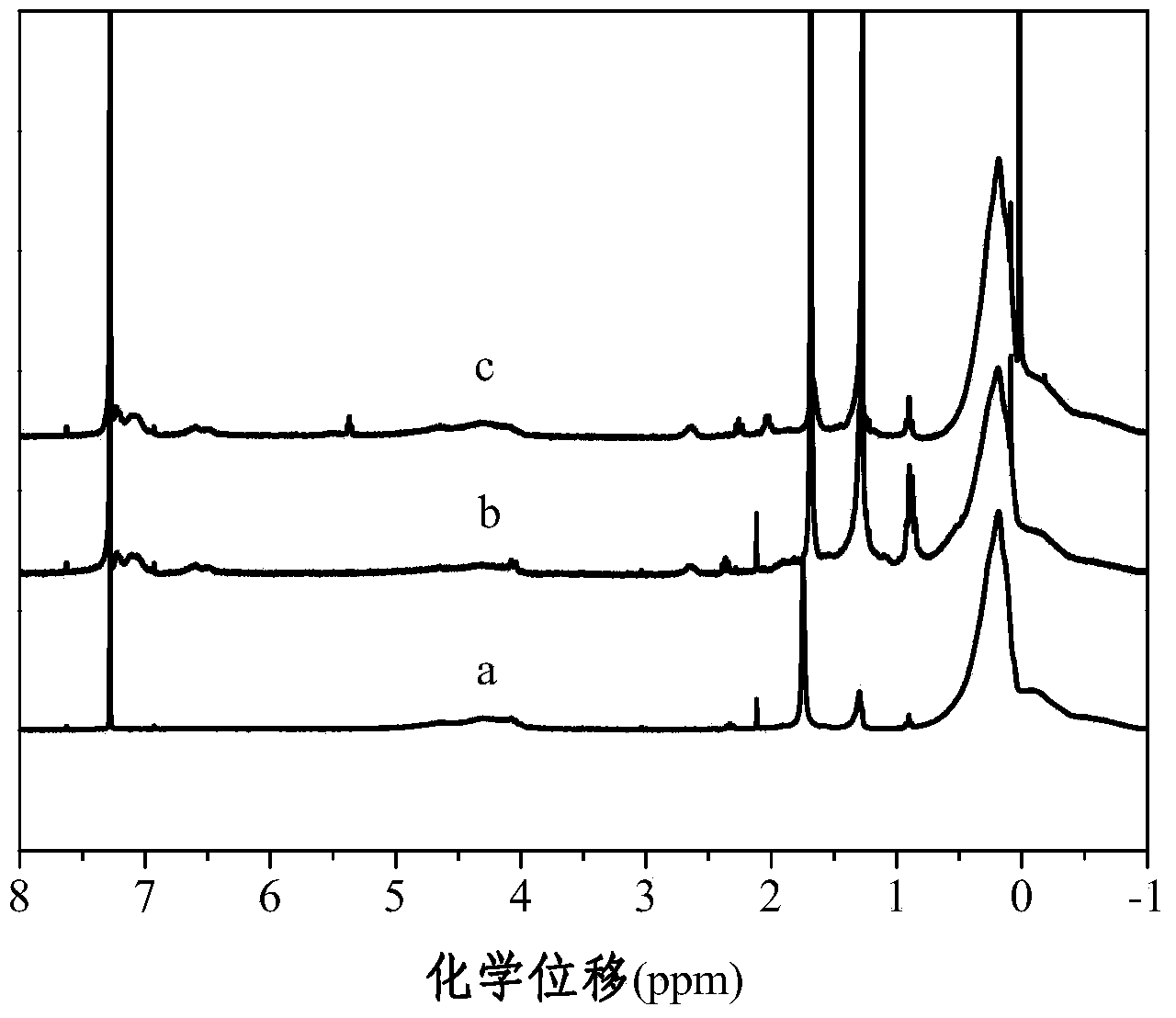

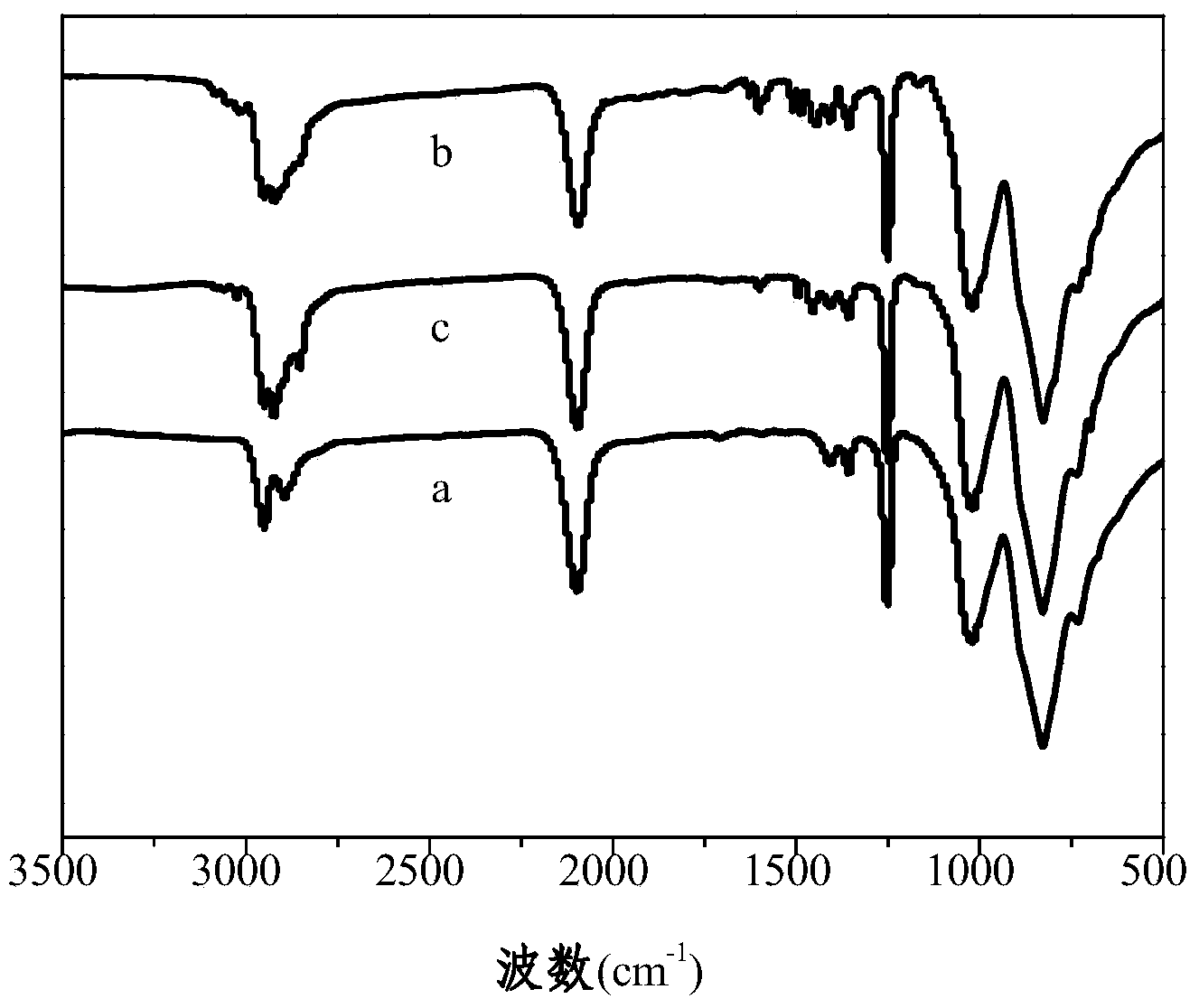

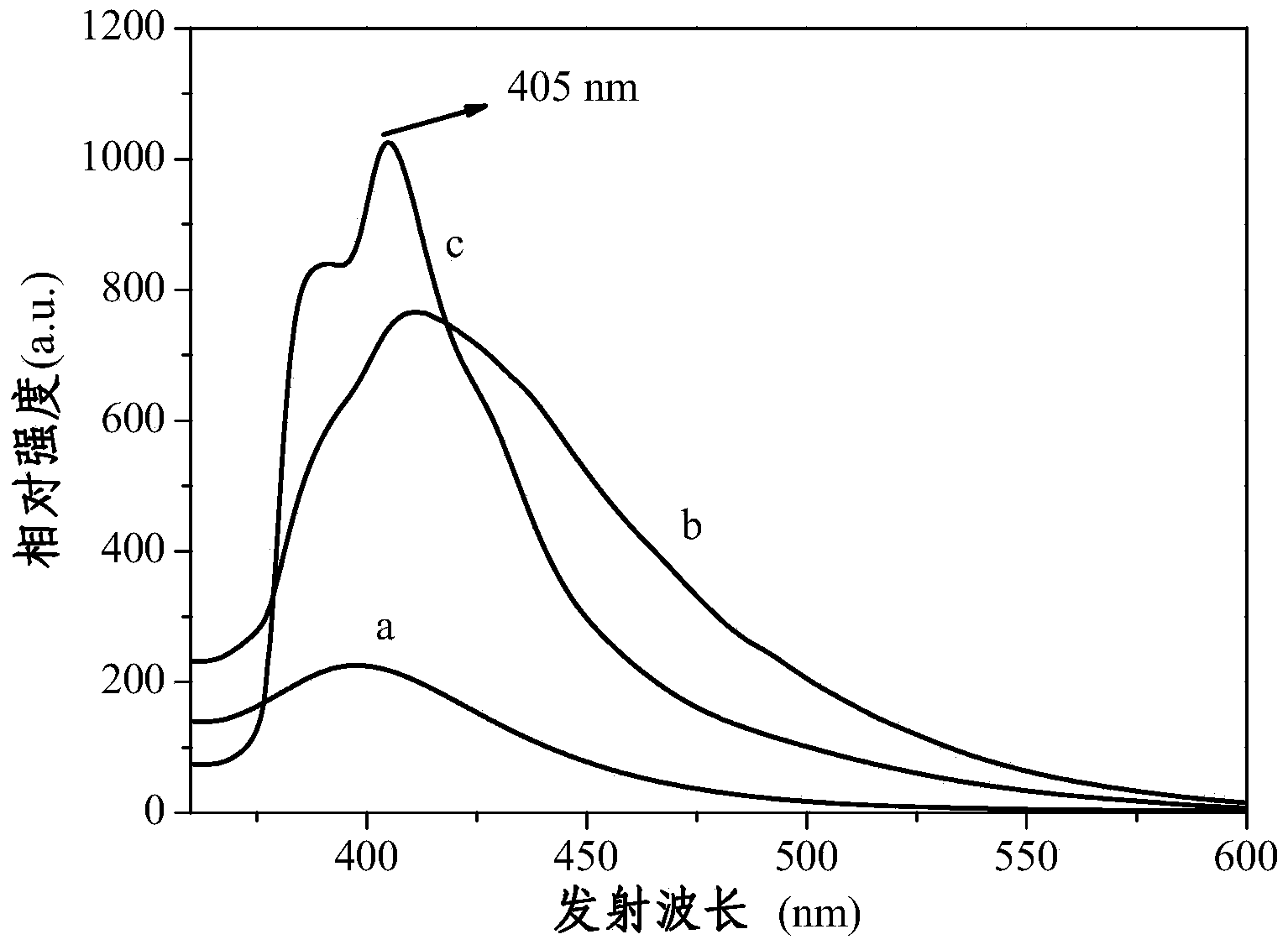

[0038] 1) Put 50g of polydimethylsiloxane (PMDS) in a closed 300ml autoclave, raise it to 300°C at 10°C / min under the protection of argon, vacuumize and keep it for 2 hours, and then fill it with argon to keep The pressure in the system is 101KPa, then rise to 390°C at 1°C / min, and keep warm for 3h. After the reaction was completed, after the temperature in the reaction kettle was naturally cooled to room temperature, n-hexane was added to dissolve the product, filtered, and n-hexane was removed in a vacuum to finally obtain pale yellow solid polycarbosilane (PCS).

[0039] 2) The product in step 1) was ground and soaked in absolute ethanol, stirred for 12 hours, and the filtered product was washed three times with absolute ethanol and then dried in a vacuum oven at 60° C. to obtain a light yellow powder.

[0040] 3) Take 5g of the product in step 2), grind it into powder and dissolve it in 30ml of xylene, then mix it evenly with 10ml of styrene, then add 1ml of chloroplatinic...

Embodiment 2

[0044] 1) Put 50g of polydimethylsiloxane in a closed 300ml high-pressure reactor, raise it to 300°C at 10°C / min under the protection of argon, vacuumize and keep it for 2 hours, and then fill it with argon to maintain the pressure in the system It is 101KPa, then raised to 390°C at 1°C / min, and kept for 3h. After the reaction was completed, after the temperature in the reaction kettle was naturally cooled to room temperature, n-hexane was added to dissolve the product, filtered, and n-hexane was removed in a vacuum to finally obtain light yellow solid PCS.

[0045] 2) The product in step 1) was ground and soaked in absolute ethanol, stirred for 12 hours, and the filtered product was washed three times with absolute ethanol and then dried in a vacuum oven at 60° C. to obtain a light yellow powder.

[0046] 3) Take 5g of the product in step 2), grind it into powder and dissolve it in 30ml of xylene, then mix it evenly with 10ml of 2-vinylnaphthalene, then add 1ml of chloroplati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com