A composite waterproof structure and preparation method

A technology of structure and waterproof membrane layer, applied in the direction of building structure, chemical instruments and methods, building components, etc., can solve the problems of delamination of paint and membrane, difficulty in ensuring waterproof quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

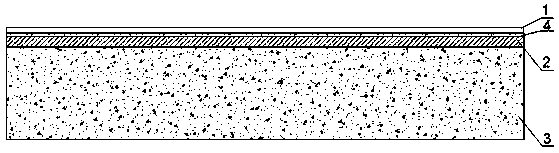

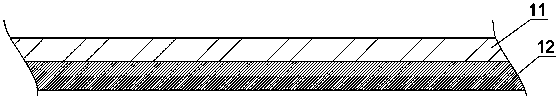

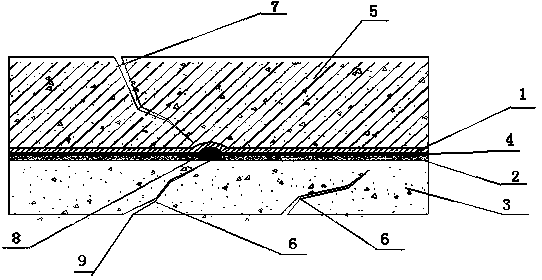

[0035] Such as figure 1 with figure 2As shown, a composite waterproof structure, from top to bottom is a waterproof coiled material layer 1, a reactive polymer elastic coating layer 2 and a waterproof base layer 3; the waterproof coiled material layer 1 is an upper surface layer from top to bottom 11 and a self-adhesive material layer 12, the upper surface layer 11 is a strong cross film layer formed by two layers of high-strength PE film crossed at an angle of 45 degrees, the self-adhesive layer 12 is a self-adhesive polymer modified asphalt, the The self-adhesive polymer modified asphalt comprises the following raw materials in parts by weight: 1 part of SBS modifier, 1 part of SBR modifier, 20 parts of naphthenic oil, and 100 parts of asphalt prepolymer;

[0036] The reactive polymer elastic coating includes component A and component B, the weight ratio of component A and component B is 1:1, and the component A includes the following raw materials in parts by weight: poly...

Embodiment 2

[0046] A composite waterproof structure, from top to bottom is a waterproof coiled material layer, a reactive polymer elastic coating layer and a waterproof base layer; the waterproof coiled material layer is an upper surface layer and a self-adhesive material layer from top to bottom, so The upper surface layer is a strong cross film layer formed by two layers of high-strength PE film obliquely crossing at 45 degrees. The self-adhesive layer is a self-adhesive polymer modified asphalt, and the self-adhesive polymer modified asphalt includes the following parts by weight The number of raw materials: 1 part of SBS modifier, 2 parts of SBR modifier, 10 parts of naphthenic oil, 90 parts of asphalt prepolymer;

[0047] The reactive polymer elastic coating includes component A and component B, the weight ratio of component A and component B is 1:2, and the component A includes the following raw materials in parts by weight: polyether 2000 50 Parts, 50 parts of asphalt prepolymer, 2...

Embodiment 3

[0056] A composite waterproof structure, from top to bottom is a waterproof coiled material layer, a reactive polymer elastic coating layer and a waterproof base layer; the waterproof coiled material layer is an upper surface layer and a self-adhesive material layer from top to bottom, so The upper surface layer is a strong cross film layer formed by two layers of high-strength PE film obliquely crossing at 45 degrees. The self-adhesive layer is a self-adhesive polymer modified asphalt, and the self-adhesive polymer modified asphalt includes the following parts by weight The number of raw materials: 2 parts of SBS modifier, 1 part of SBR modifier, 15 parts of naphthenic oil, 95 parts of asphalt prepolymer;

[0057] The reactive polymer elastic coating includes component A and component B, the weight ratio of component A and component B is 1:1.5, and the component A includes the following raw materials in parts by weight: polyether 2000 40 40 parts of asphalt prepolymer, 17 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com