A kind of preparation method of titanium-nickel medical implant material

An implant material and medical technology, which is applied in the field of surface modification of rare metal materials, can solve the problems of easily forming cavities on the surface of micro-arc oxidation film and affecting surface properties, so as to reduce the formation of cavities, good wear resistance and thermal shock resistance, and Erosion-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

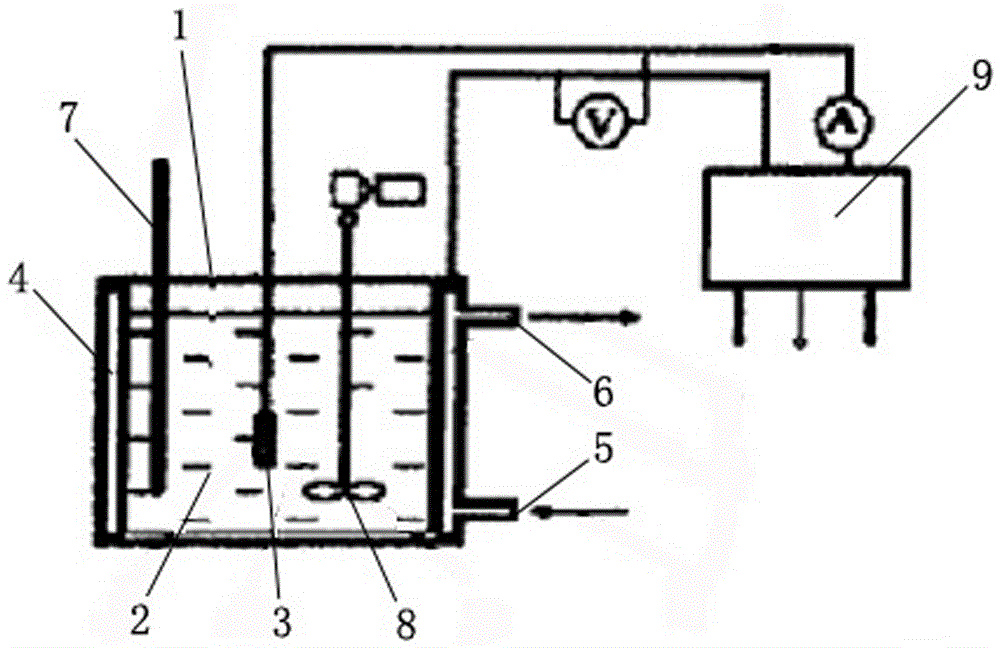

Image

Examples

Embodiment 1

[0027] A method for preparing a titanium-nickel medical implant material. Firstly, plasma alloying technology is used to infiltrate titanium on the surface of a titanium-nickel alloy workpiece to form a deposition layer, and then TiO is formed on the surface of the deposition layer by micro-arc oxidation. 2 and Al 2 o 3 mixed oxide coating;

[0028] Specifically include the following steps:

[0029]1) Take the titanium-nickel alloy substrate, cut it into Φ20mm×4mm as the workpiece, and remove the oxide film on the surface of the workpiece by mechanical and chemical mixing methods. The specific process is: use metallographic sandpaper to roughly grind the surface of the workpiece, and then sandblast the surface of the workpiece Grinding, then ultrasonic cleaning the surface of the workpiece, and finally drying;

[0030] 2) In the plasma surface alloying metal infiltration furnace, the source electrode selects a pure titanium target with a purity of 99.99%, and the workpiece ...

Embodiment 2

[0041] A method for preparing a titanium-nickel medical implant material. Firstly, plasma alloying technology is used to infiltrate titanium on the surface of a titanium-nickel alloy workpiece to form a deposition layer, and then TiO is formed on the surface of the deposition layer by micro-arc oxidation. 2 and Al 2 o 3 mixed oxide coating;

[0042] Specifically include the following steps:

[0043] 1) Take the titanium-nickel alloy substrate, cut it into Φ20mm×4mm as the workpiece, and remove the oxide film on the surface of the workpiece by mechanical and chemical mixing methods. The specific process is: use metallographic sandpaper to roughly grind the surface of the workpiece, and then sandblast the surface of the workpiece Grinding, then ultrasonic cleaning the surface of the workpiece, and finally drying;

[0044] 2) In the plasma surface alloying metal infiltration furnace, the source electrode selects a pure titanium target with a purity of 99.99%, and the workpiece...

Embodiment 3

[0055] A method for preparing a titanium-nickel medical implant material. Firstly, plasma alloying technology is used to infiltrate titanium on the surface of a titanium-nickel alloy workpiece to form a deposition layer, and then TiO is formed on the surface of the deposition layer by micro-arc oxidation. 2 and Al 2 o 3 mixed oxide coating;

[0056] Specifically include the following steps:

[0057] 1) Take the titanium-nickel alloy substrate, cut it into Φ20mm×4mm as the workpiece, and remove the oxide film on the surface of the workpiece by mechanical and chemical mixing methods. The specific process is: use metallographic sandpaper to roughly grind the surface of the workpiece, and then sandblast the surface of the workpiece Grinding, then ultrasonic cleaning the surface of the workpiece, and finally drying;

[0058] 2) In the plasma surface alloying metal infiltration furnace, the source electrode selects a pure titanium target with a purity of 99.99%, and the workpiece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com