A method for preparing colored superhydrophobic stainless steel based on alkaline electrochemical coloring

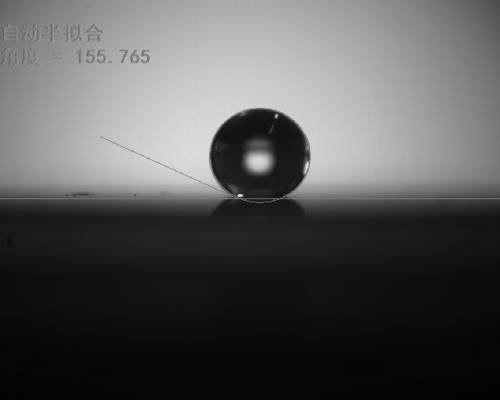

A stainless steel, super-hydrophobic technology, applied in the direction of anodic oxidation, coating, etc., can solve the problems of uneven coloring of coloring technology, easy adhesion of pollutants on the surface, poor long-term service stability, etc., and achieve low voltage value and dense adhesion , Prolong the effect of coloring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing golden yellow superhydrophobic stainless steel based on alkaline electrochemical coloring, comprising the following steps:

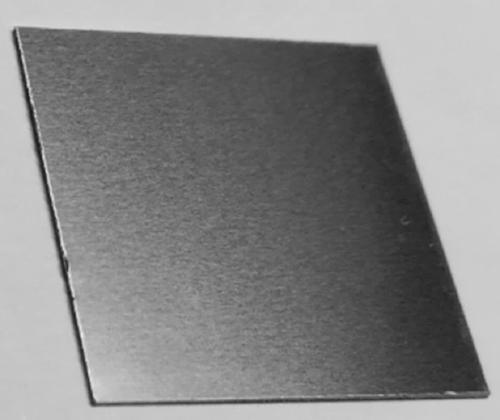

[0036] (1) Clean the stainless steel surface: Cut 0.27mm thick 304 stainless steel into strips of 50×20mm, and then ultrasonically clean the stainless steel in acetone, absolute ethanol, and deionized water to remove oil stains on the surface ;

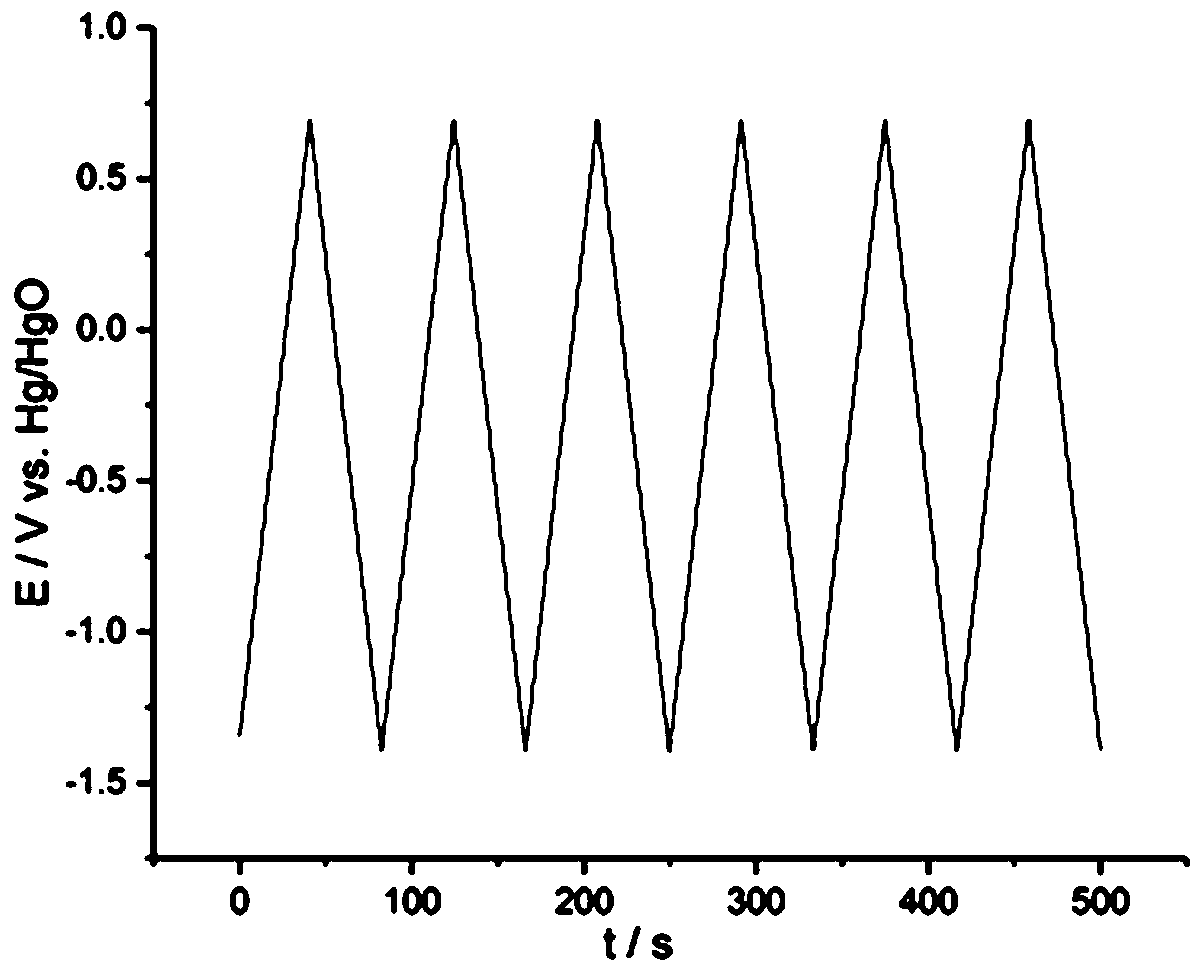

[0037] (2) Place the stainless steel treated in step (1) in an alkaline coloring solution, use the stainless steel as the working electrode, the platinum electrode as the counter electrode, and the mercury / mercury oxide electrode (electrolyte is 1mol / LKOH) as the reference electrode , carry out triangular wave potential coloring to stainless steel at 60 ℃, during the coloring process, alkaline coloring solution is stirred, stirring speed is 200rpm, after coloring is finished, through water washing, drying, obtain golden yellow stainless steel (the photo of this golden yellow stainle...

Embodiment 2

[0042] A method for preparing purple superhydrophobic stainless steel based on alkaline electrochemical coloring, comprising the following steps:

[0043] (1) Clean the stainless steel surface: Cut 0.27mm thick 304 stainless steel into strips of 50×20mm, and then ultrasonically clean the stainless steel in acetone, absolute ethanol, and deionized water to remove oil stains on the surface ;

[0044] (2) Place the stainless steel treated in step (1) in an alkaline coloring solution, use the stainless steel as the working electrode, the platinum electrode as the counter electrode, and the mercury / mercury oxide electrode (electrolyte is 1mol / LKOH) as the reference electrode , coloring the stainless steel with triangular wave potential at 60°C. During the coloring process, the alkaline coloring solution is magnetically stirred at a stirring rate of 200rpm. After the coloring is completed, it is washed with water and dried to obtain purple stainless steel. Use a color difference met...

Embodiment 3

[0049] A method for preparing green superhydrophobic stainless steel based on alkaline electrochemical coloring, comprising the following steps:

[0050] (1) Clean the stainless steel surface: Cut 0.27mm thick 304 stainless steel into strips of 50×20mm, and then ultrasonically clean the stainless steel in acetone, absolute ethanol, and deionized water to remove oil stains on the surface ;

[0051] (2) Place the stainless steel treated in step (1) in an alkaline coloring solution, use the stainless steel as the working electrode, the platinum electrode as the counter electrode, and the mercury / mercury oxide electrode (electrolyte is 1mol / LKOH) as the reference electrode , coloring the stainless steel with triangular wave potential at 60°C. During the coloring process, the alkaline coloring solution was stirred at a stirring rate of 300rpm. After the coloring was completed, the green stainless steel was obtained by washing with water and drying. The average value, the brightnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com