Composite wallboard structures and composite wall

A technology of composite wall panels and panels, applied in the direction of walls, building components, building structures, etc., can solve the problems of panel design, processing and installation difficulty, and achieve the effect of convenient installation and connection and fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

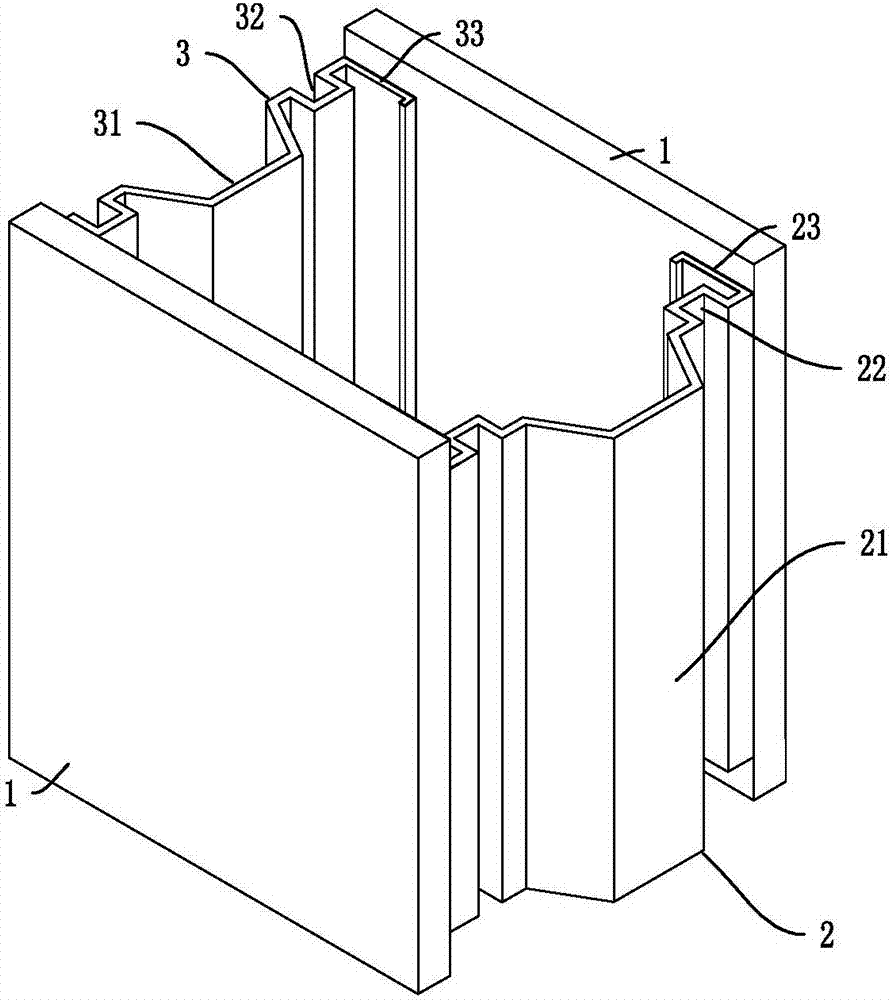

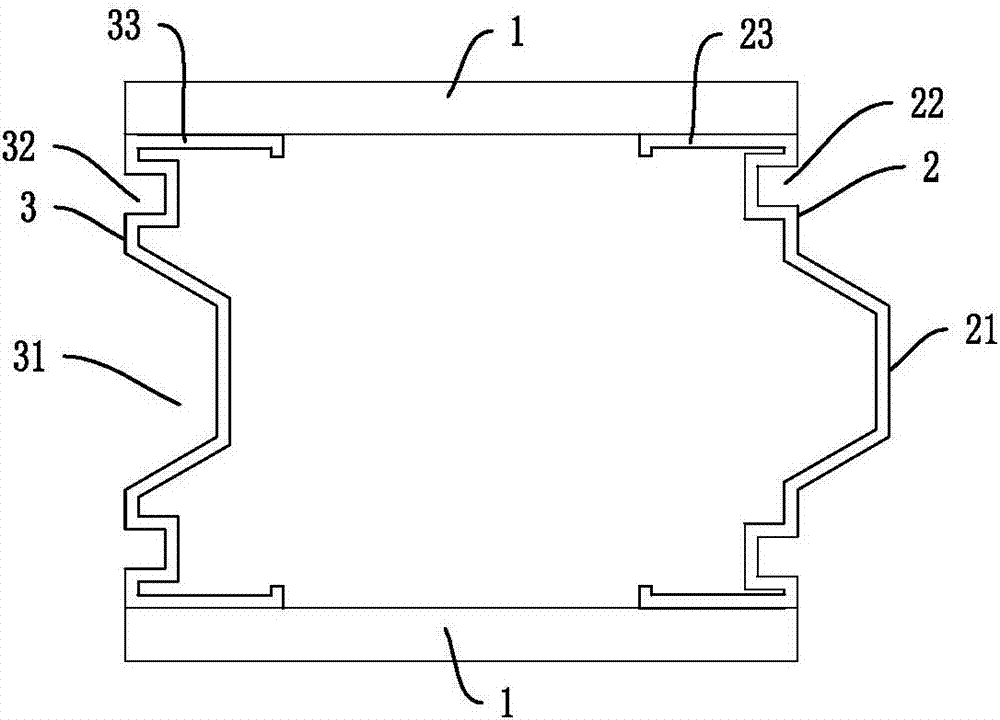

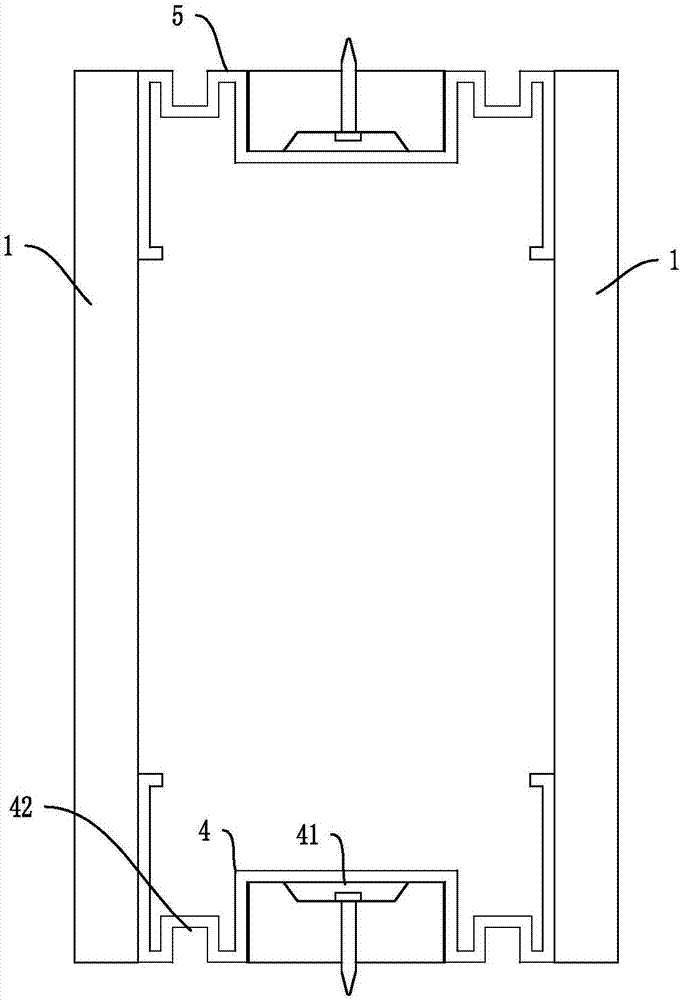

[0022] Such as Figure 1 to Figure 3 The composite wallboard structure shown includes two facing panels 1, and the two panels 1 are made of the same material and have the same size. The two panels 1 are connected through a metal keel frame. The two panels 1 and the keel frame form a cavity, and there is a filler not shown in the cavity. The filler can be one of refractory materials, sound insulation materials, and thermal insulation materials, so that the composite wallboard Structures have different functions and are suitable for different occasions. When assembling the wall panel structure, put the filler between the two panels, then use the keel frame to surround the filler, and connect the filler, the keel frame and the two panels as a whole.

[0023] The keel frame includes a first keel 2 and a second keel 3 arranged along the height direction of the panel 1, and the first keel 2 and the second keel 3 are arranged in opposite directions in parallel and are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com