Assembled hoisting platform structure and construction method thereof

A platform structure and assembly technology, which is applied in the direction of housing structure support, housing structure support, scaffolding supported by housing structure, etc., can solve the problems of difficult design of the hanging platform below, large on-site welding workload, and irregular platform layout. , to achieve the effect of reducing the measurement workload, the on-site welding volume is small, and the measurement work is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

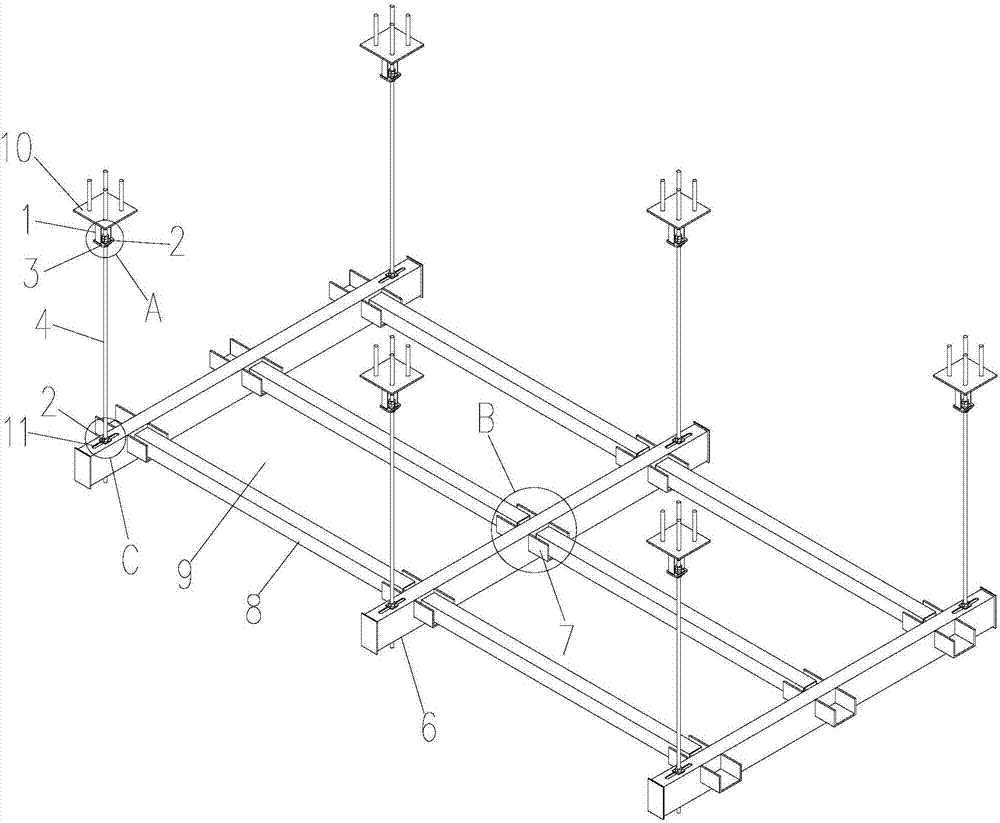

[0017] Such as Figure 1-4 As shown, a prefabricated suspension platform structure, the platform structure is arranged on the bottom of the building, including several rectangular tube main beams 6, adjacent rectangular tube main beams 6 are connected by several rectangular tube secondary beams 8, adjacent rectangular tube secondary beams Platform planks 9 are arranged between the beams 8 ; round steel suspenders 4 are arranged at both ends of each rectangular tube main beam 6 , and the round steel suspenders 4 are connected to the floor surface through embedded parts 10 .

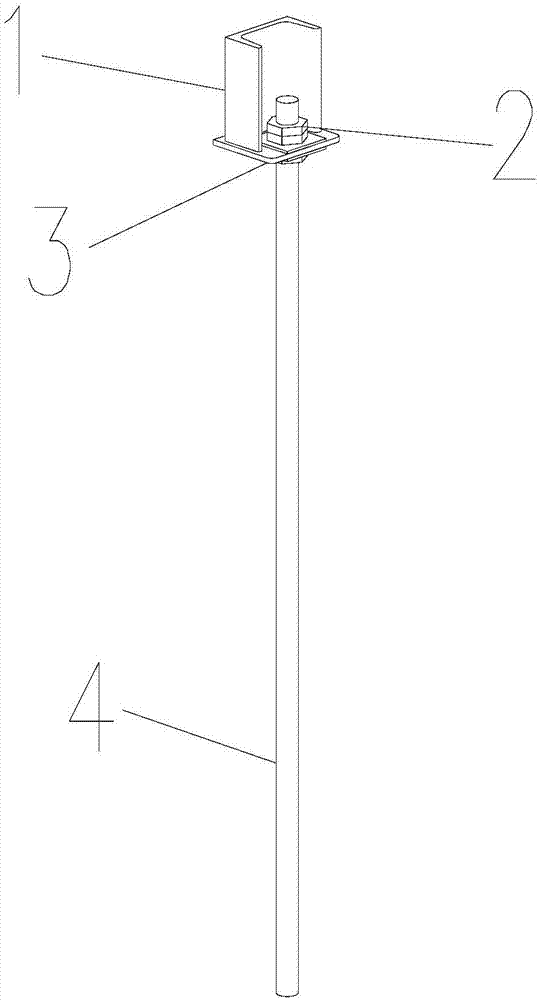

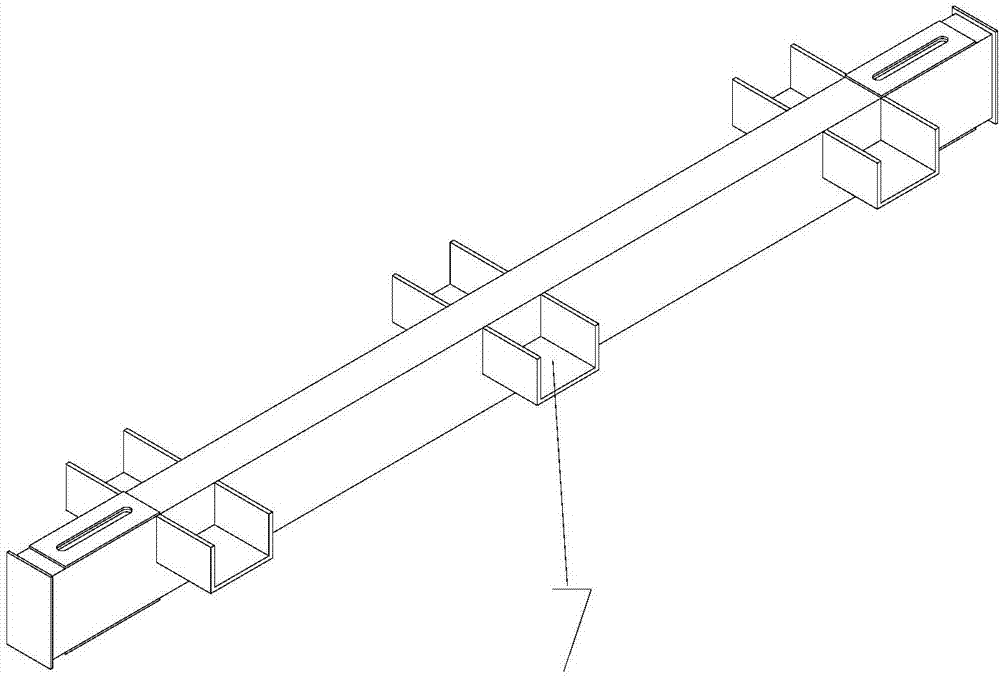

[0018] An adapter 7 is provided at the junction of the rectangular tube main beam 6 and the rectangular tube secondary beam 8, and the adapter 7 is a U-shaped steel channel.

[0019] A channel steel connector 1 is fixed on the bottom of the embedded part 10 , a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com