Prestress CFST thin wall box-type section component

A technology of prestressing and prestressing steel bar, which is applied in the direction of long strip structural components, building components, arched beams, etc. for load bearing, can solve the problems of poor stability, low rigidity, welding residual stress, etc., and achieve weight reduction, Good seismic performance and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

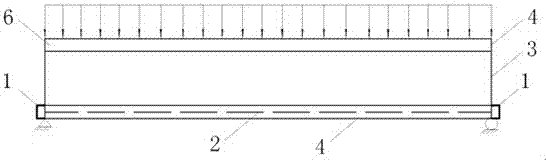

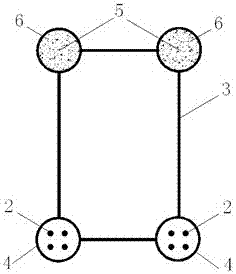

[0036] combine figure 1 , figure 2 As shown, the prestressed CFST member of this embodiment is a closed box section, the steel pipe is located at the corner of the section, and the steel pipe 4 is welded to the thin-walled steel plate 3 . The steel pipe 4 located in the middle of the entire section and on the axial compression side is filled with concrete 5 to form the steel pipe concrete 6 to bear the compressive stress caused by the bending moment; the steel pipe 4 located in the entire section and on the axial tension side is provided with prestressed steel bars 2, Anchorages 1 are provided at both ends of the component, and the stiffness and bending capacity of the entire component can be effectively improved after prestressing the component. The cross-section of the components in this embodiment is rectangular as a whole, and can also be designed as other polygonal cross-sections such as squares, triangles, and trapezoids. The components can be disassembled into several...

Embodiment 2

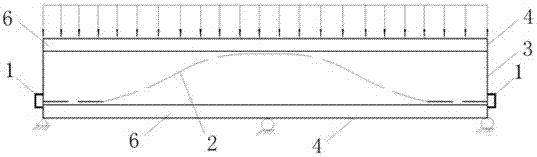

[0040] combine image 3 , Figure 4 The difference between the structure of this embodiment and Example 1 is that all steel pipes 4 are filled with concrete 5 to form steel pipe concrete 6, and the prestressed steel bars 2 are arranged near the edge of the tension zone in the box-shaped space. The figure is a rectangular cross-section member, and it can also be designed as a square, triangle, trapezoid and other polygonal cross-section forms. Other components are the same as in Embodiment 1.

Embodiment 3

[0042] combine Figure 5 , Image 6 As shown, this implementation part is a prestressed CFST box section member bearing axial pressure, prestressed steel bars 2 are arranged in each steel pipe 4, and concrete 5 is filled in the steel pipe 4 and the box section to form a steel tube concrete 6. The figure is a rectangular cross-section member, and it can also be designed as a square, triangle, trapezoid and other polygonal cross-section forms. Other components are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com