Fuel oil system of excavator

A technology of fuel system and excavator, which is applied in the direction of charging system, soil mover/shovel machine, mechanical equipment, etc. It can solve the problems of high energy loss in fuel oil circuit, high working intensity of electronic pump, and poor fuel supply of engine, etc. problems, to achieve the effect of improving fuel utilization, shortening the length of the pipeline, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

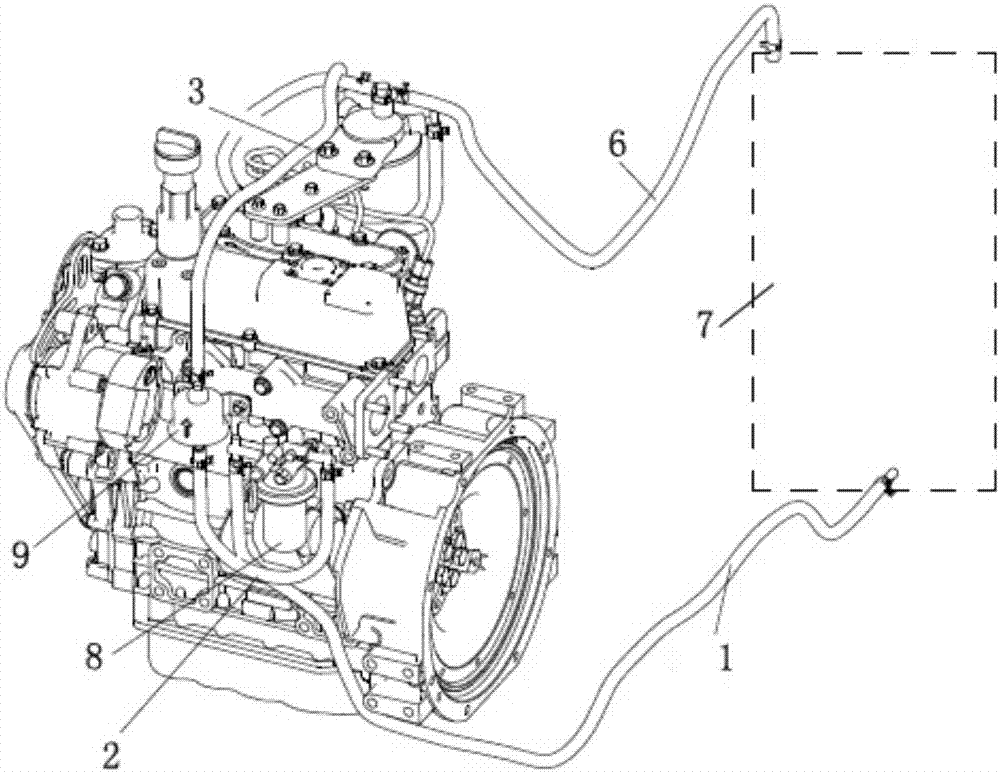

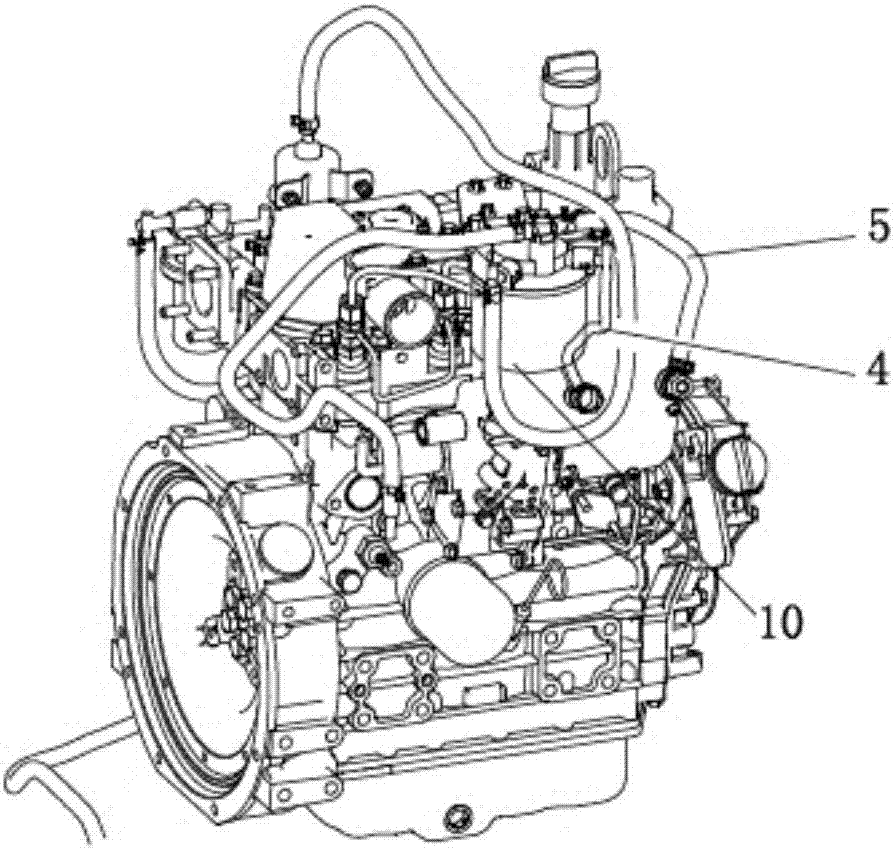

[0018] Such as figure 1 with figure 2 As shown, an excavator fuel system includes a fuel tank 7, an oil-water separator 8, an electronic pump 9, a fine fuel filter 10, an engine and a fuel delivery pipeline. The oil-water separator 8 and the electronic pump 9 are located on the same side of the engine, and the fine fuel filter 10 is located on the other side of the engine. The fuel delivery pipeline includes a first fuel delivery pipeline 1, a second fuel delivery pipeline 2, a third fuel delivery pipeline 3, a fourth fuel delivery pipeline 4, a first oil return pipeline 5 and a second oil return pipeline 6, and the fuel tank 7 passes through the first oil delivery pipeline A fuel pipeline 1 is connected to the oil-water separator 8, the oil-water separator 8 is connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap