De-dusting cable tray

A cable tray and cable technology, applied in the direction of electrical components, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of poor heat dissipation of cables and easy accumulation of dust, so as to improve cleanliness, ensure current carrying capacity, and reduce fire hazards hazard risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

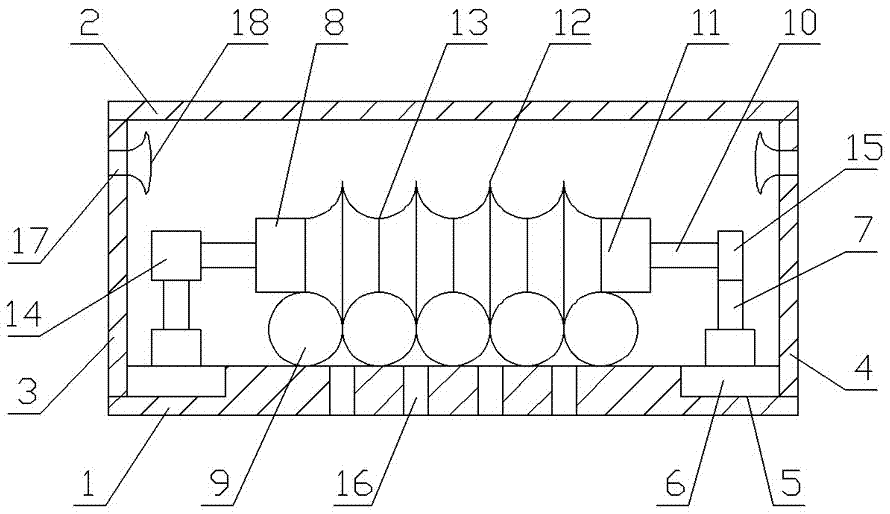

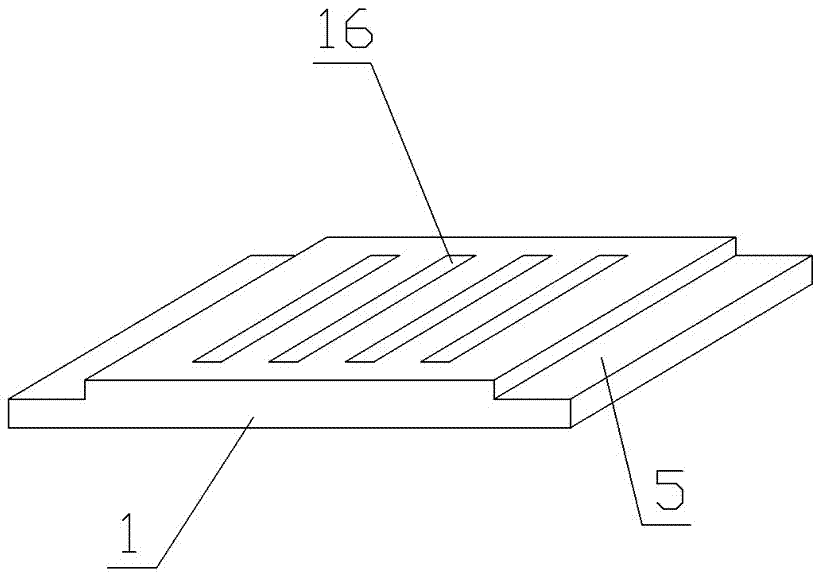

[0029] Such as Figure 1 to Figure 3 As shown, in the cable tray, slide rails 5 are provided on the left and right sides of the bottom plate 1, and a conveyor belt 6 is provided inside the slide rail 5. Vertical rods 7 are fixed on the conveyor belt 6, and the vertical rods 7 on the left and right sides are connected to each other. There is a cleaning brush 8 placed horizontally, and the bottom of the cleaning brush 8 is in close contact with the top of the cable 9; the conveyor belt 6 is connected with the central controller through an electric signal.

[0030] The cleaning brush 8 includes a brush handle 10 and a cylindrical brush head 11 wrapped on the outside of the brush handle 10; the surface of the brush head 11 is provided with protruding protruding portions 12, and recesses 13 are formed between adjacent protruding portions 12; The recessed part 13 is in close contact with the top surface of the cable 9 , and the pointed protrusion 12 is in close contact with the rece...

Embodiment 2

[0036] Such as Figure 1 to Figure 3 As shown, in the cable tray, slide rails 5 are provided on the left and right sides of the bottom plate 1, and a conveyor belt 6 is provided inside the slide rail 5. Vertical rods 7 are fixed on the conveyor belt 6, and the vertical rods 7 on the left and right sides are connected to each other. There is a cleaning brush 8 placed horizontally, and the bottom of the cleaning brush 8 is in close contact with the top of the cable 9; the conveyor belt 6 is connected with the central controller through an electric signal.

[0037] The cleaning brush 8 includes a brush handle 10 and a cylindrical brush head 11 wrapped on the outside of the brush handle 10; the surface of the brush head 11 is provided with protruding protruding portions 12, and recesses 13 are formed between adjacent protruding portions 12; The recessed part 13 is in close contact with the top surface of the cable 9 , and the pointed protrusion 12 is in close contact with the rece...

Embodiment 3

[0042] Such as Figure 1 to Figure 3 As shown, in the cable tray, slide rails 5 are provided on the left and right sides of the bottom plate 1, and a conveyor belt 6 is provided inside the slide rail 5, and vertical rods 7 are fixed on the conveyor belt 6, and the vertical rods 7 on the left and right sides are connected There is a cleaning brush 8 placed horizontally, and the bottom of the cleaning brush 8 is in close contact with the top of the cable 9; the conveyor belt 6 is connected with the central controller through an electric signal.

[0043] The cleaning brush 8 includes a brush handle 10 and a cylindrical brush head 11 wrapped outside the brush handle 10; the surface of the brush head 11 is provided with outwardly protruding pointed portions 12, and recessed portions 13 are formed between adjacent pointed portions 12; The recessed part 13 is in close contact with the top surface of the cable 9 , and the pointed protrusion 12 is in close contact with the recess forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com