Core filter net of air purifier of high mercury workshop and preparation method and application thereof

An air purifier and filter screen technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., to achieve cost savings, huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

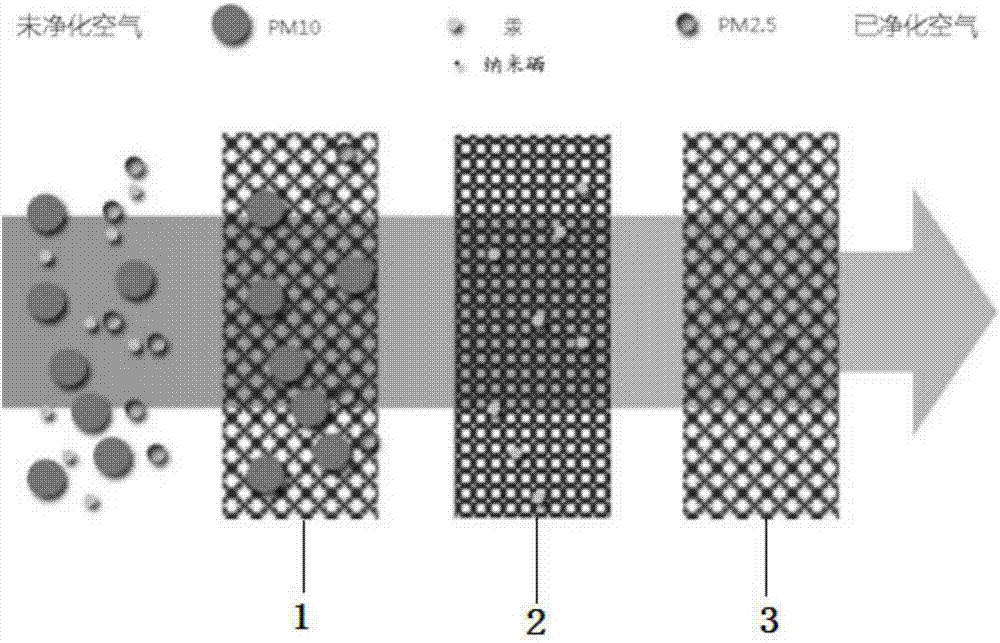

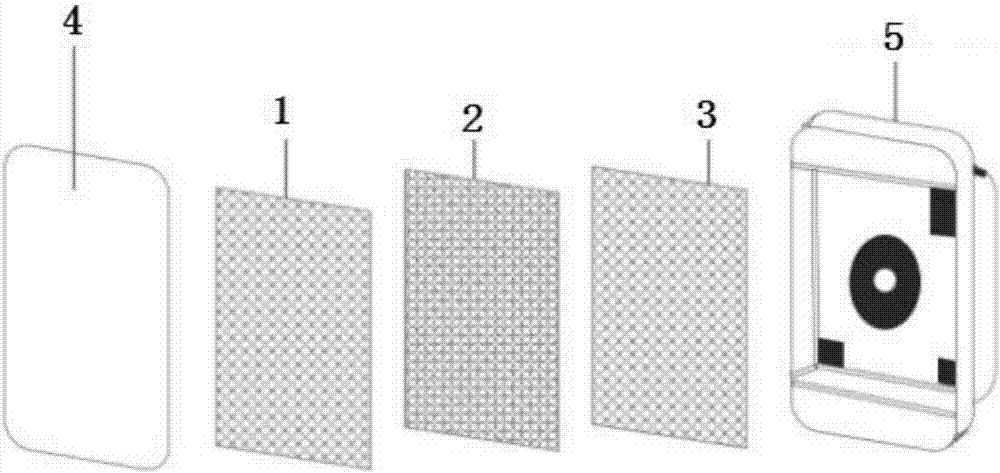

Method used

Image

Examples

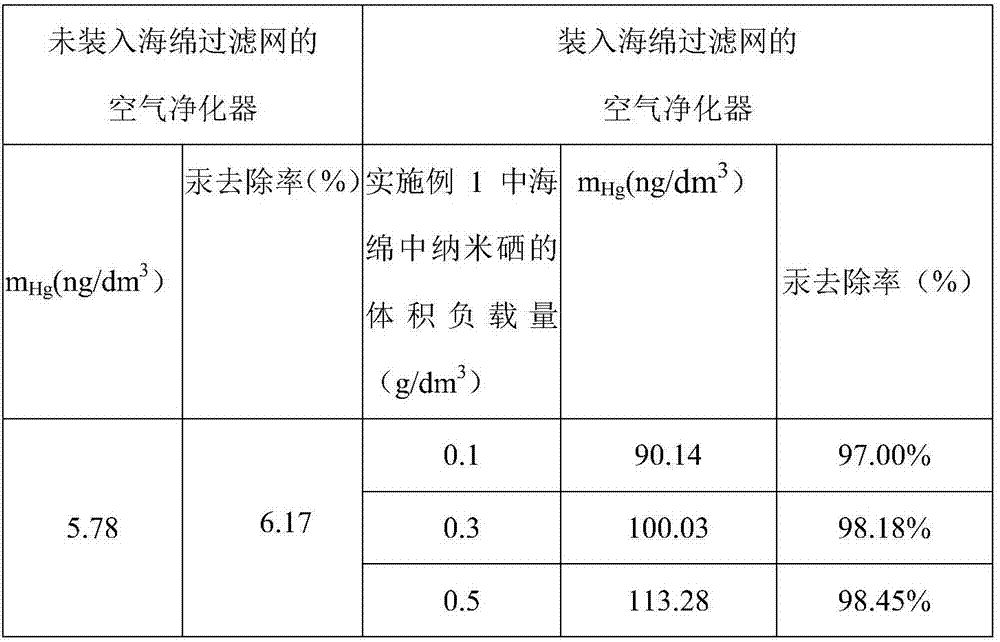

Embodiment 1

[0031] Preparation of sponge loaded with nano-selenium

[0032] Disperse 1.6g of dopamine hydrochloride in 5L of deionized water, stir evenly, and stir the reaction with a constant temperature magnetic stirrer at 20°C for 3 hours at a speed of 500r / min. After a period of reaction, the solution in the beaker changes from colorless to Turn brown into black again; After obtaining described polydopamine aqueous solution, add the sponge that size is 250W*5D*385H (sponge volume is 0.5dm 3 ), stirred and adsorbed with a constant temperature magnetic stirrer at 25°C for 1 hour, after a period of adsorption, the solution changed from black to brown. The above same steps were repeated for 3 groups, which were recorded as experimental groups 1, 2, and 3. Add sodium selenite crystal 0.87g, 2.61g, 4.35g respectively in experimental group 1,2,3 so that the concentration of sodium selenite is respectively 0.001mol / L, 0.003mol / L, 0.005mol / L, then Add 1.76g, 3.52g, and 8.8g of L-ascorbic aci...

Embodiment 2

[0035] Preparation of sponge loaded with nano-selenium

[0036] Disperse 16g of dopamine hydrochloride in 5L of deionized water, stir evenly, and stir the reaction with a constant temperature magnetic stirrer at 30°C for 8 hours at a speed of 2000r / min. After a period of reaction, the solution in the beaker changes from colorless to Be brown and become black again; After obtaining described polydopamine aqueous solution, add the sponge that size is 250W*50D*385H (sponge volume is 5dm 3 ), stirred and adsorbed with a constant temperature magnetic stirrer for 3 hours at 25°C, after a period of adsorption, the solution changed from black to brown. The above same steps were repeated for 3 groups, which were recorded as experimental groups 1, 2, and 3. Add sodium selenite crystal 4.35g, 8.7g, 17.4g respectively in experimental group 1,2,3 so that the concentration of sodium selenite is respectively 0.005mol / L, 0.01mol / L, 0.02mol / L, then Add 8.8g, 17.6g, and 35.2g of L-ascorbic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com