A method for producing large-width and large-area stainless steel composite panels

A production method, stainless steel technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of high investment and production costs, difficult product quality control, low production efficiency, etc., to improve production efficiency. , The effect of reducing welding workload and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 1. Blank design:

[0044] (1) According to the total thickness of the finished stainless steel clad plate, the thickness of the finished clad layer, the thickness of the finished base layer, the thickness ratio of the finished base clad layer, and according to the deformation law of the clad plate and the base plate during rolling, the total reduction rate is calculated at 80 %, the total thickness of the composite slab and the thickness of the composite slab and the base plate can meet the design requirements, and determine the thickness of the stainless steel double plate and carbon steel base plate and the total thickness of the composite slab for explosive billet making;

[0045] The calculation formula of the total thickness H of the stainless steel clad slab is: H=h / (1- );

[0046] Stainless steel cladding thickness H f The calculation formula is: H f = h f / (1- ) / k;

[0047] Carbon steel substrate thickness H j The calculation formula is: H j = H-h...

Embodiment 2

[0086] Step 1. Blank design:

[0087] (1) According to the total thickness of the finished stainless steel clad plate, the thickness of the finished clad layer, the thickness of the finished base layer, and the thickness ratio of the base clad layer, according to the deformation law of the clad plate and the base plate during rolling, the total reduction rate is calculated at 90% When the thickness of double plate and base plate can meet the design requirements, determine the thickness of stainless steel double plate and carbon steel base plate for explosive billet making;

[0088] The calculation formula of the total thickness H of the stainless steel clad slab is: H=h / (1- );

[0089] Stainless steel cladding thickness H f The calculation formula is: H f = h f / (1- ) / k;

[0090] Carbon steel substrate thickness H j The calculation formula is: H j = H-h f / (1- ) / k;

[0091] In the formula: h is the total thickness of the finished stainless steel clad plate;

[0...

Embodiment 3

[0129] Step 1. Blank design:

[0130] 304 stainless steel is selected as the double plate, and the explosion-welded slab of Q235B is selected as the substrate. The thickness of the 304 stainless steel is 20mm, the thickness of the Q235B steel plate is 100mm, and the total thickness is 120mm; the width of the stainless steel double plate is 1380mm, and the length is 2580mm; the width of the carbon steel substrate is 1340mm, and the length is 2540mm;

[0131] Step two, slab surface cleaning:

[0132] Grinding the two composite surfaces of the stainless steel cladding plate and the carbon steel substrate after billeting to remove rust, oil and other dirt on the surface of the steel plate;

[0133] Step 3. Explosive billet making:

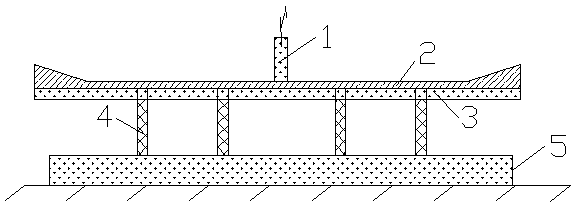

[0134] Such as figure 1 As shown, the edge triangular ladder distribution method and the center detonation method are used for explosive billet making: an explosive layer 2 is set on the stainless steel doubler plate 3, and the explosive layer 2 use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com