Spindle taper hole grinding miller and online repairing method for spindle taper hole

A grinding machine and spindle technology, which is applied in the direction of grinding frame, grinding machine parts, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve problems affecting normal work, improve repair accuracy, and reduce downtime The effect of time, recovery geometric accuracy and shape and position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the drawings and specific embodiments.

[0031] In the following description, it is assumed that the installation position of the grinding wheel is in the front, the installation position of the hand wheel 22 is in the rear, and the actual installation position is deduced by analogy.

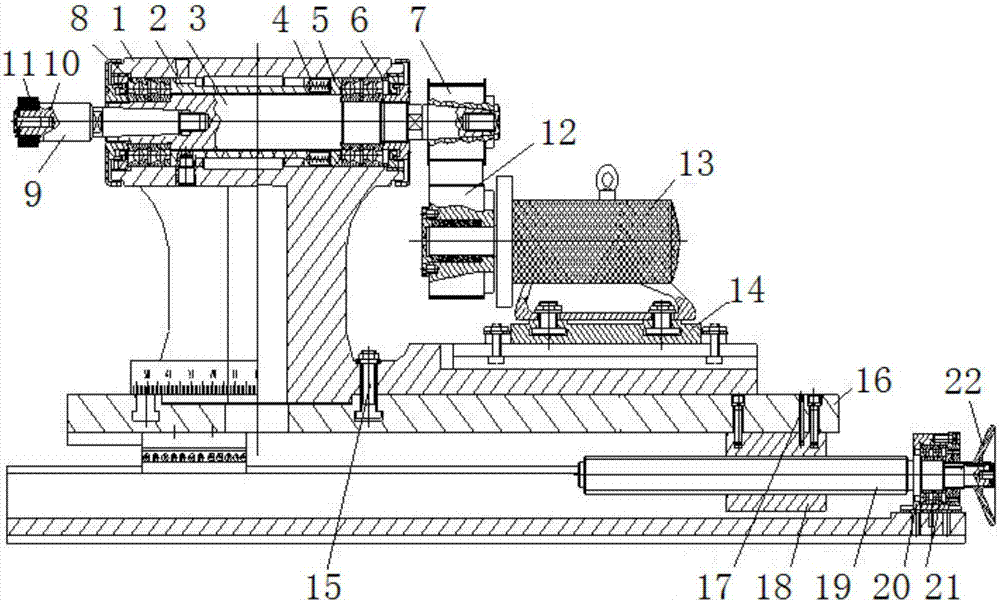

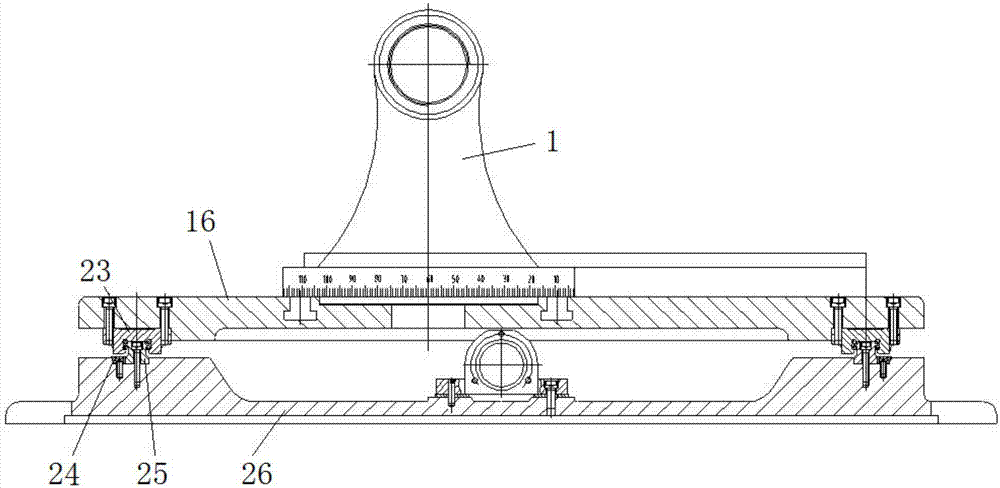

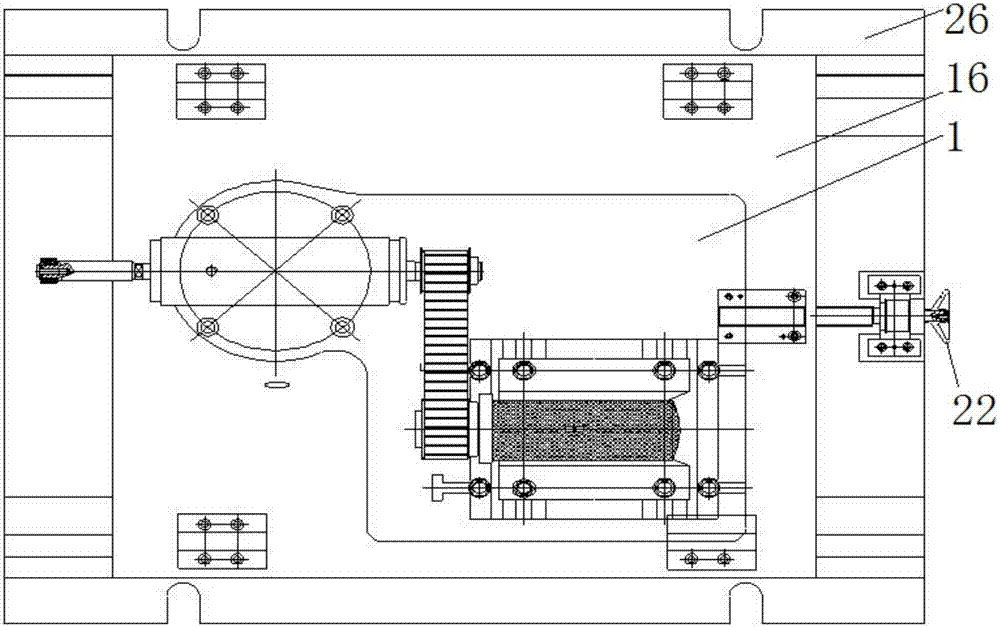

[0032] Reference figure 1 , figure 2 , image 3 , The structure of the device of the present invention is to include a lower seat 26, the lower seat 26 is fixed on the work surface of the machine tool, the lower seat 26 is upwardly connected to the upper slide 16 through two sets of rolling linear guide pairs, the upper slide 16 and the lower seat 26 A screw drive mechanism is additionally provided between the upper sliding seat 16 and the upper surface of the upper sliding seat 16 is installed with a spindle housing 1 which is connected to the upper sliding seat 16 through a fastening component 15; the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com