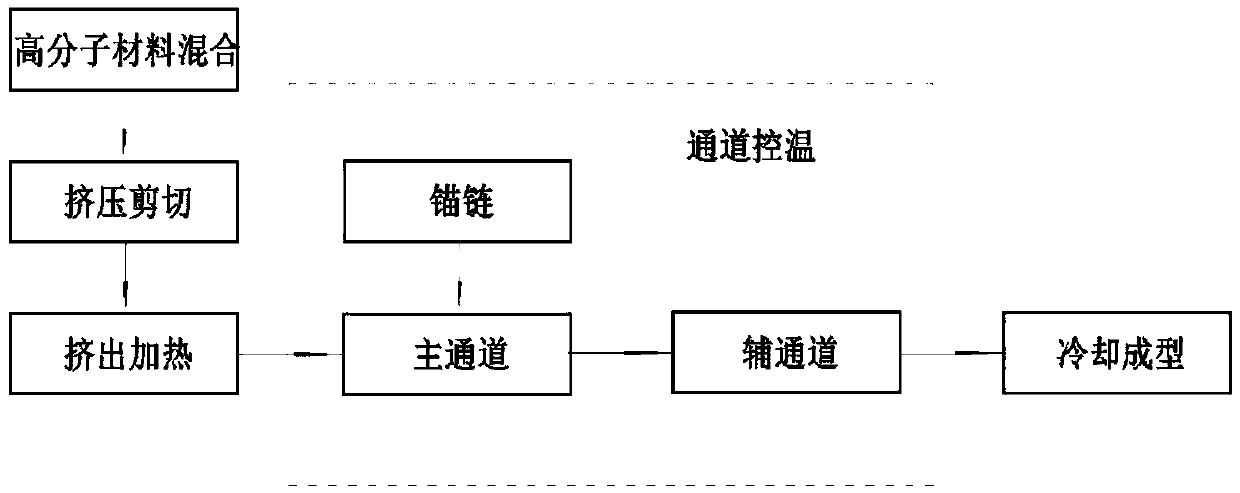

One-time rapid prototyping method for plastic coating of elevator balance compensation chain

A technology of balance compensation and molding method, which can be applied to other household appliances, coatings, household appliances, etc., which can solve the problems of easy aging of materials, uneconomical, cumbersome production processes, etc., to improve product quality, prolong service life, and reduce energy consumption. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

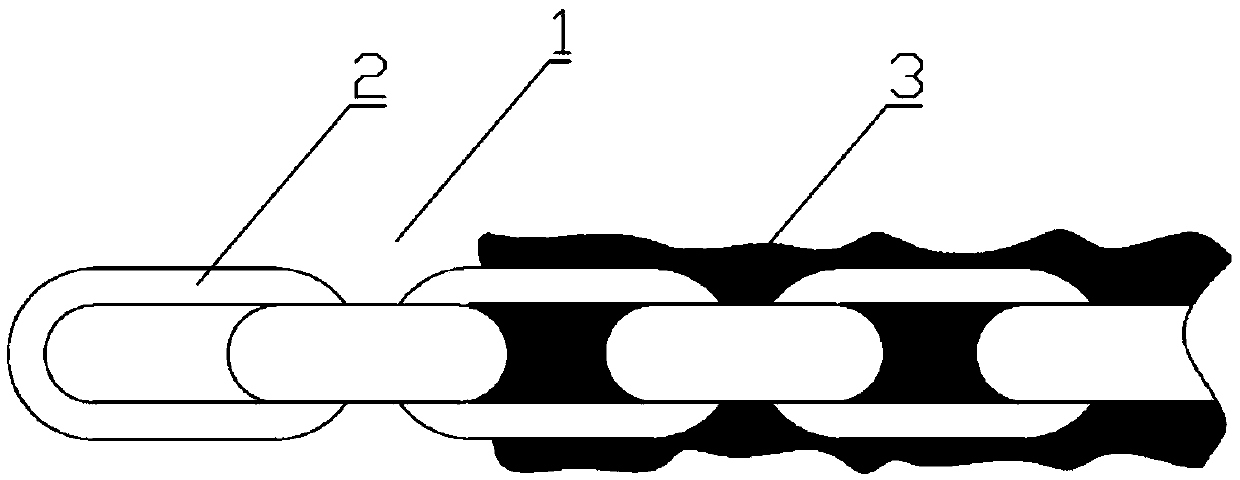

[0047] The multi-channel temperature control step is five-channel temperature control, and the five-channel temperature control of the five channels includes a main channel and four auxiliary channels, and the cross-sectional shapes of the four sections of the auxiliary channels are as follows: Figure 4 As shown, the main channel forms an initial wrapping effect on the anchor chain, and the four auxiliary channels wrap the anchor chain passing through the main channel in all directions from the four sections.

Embodiment 2

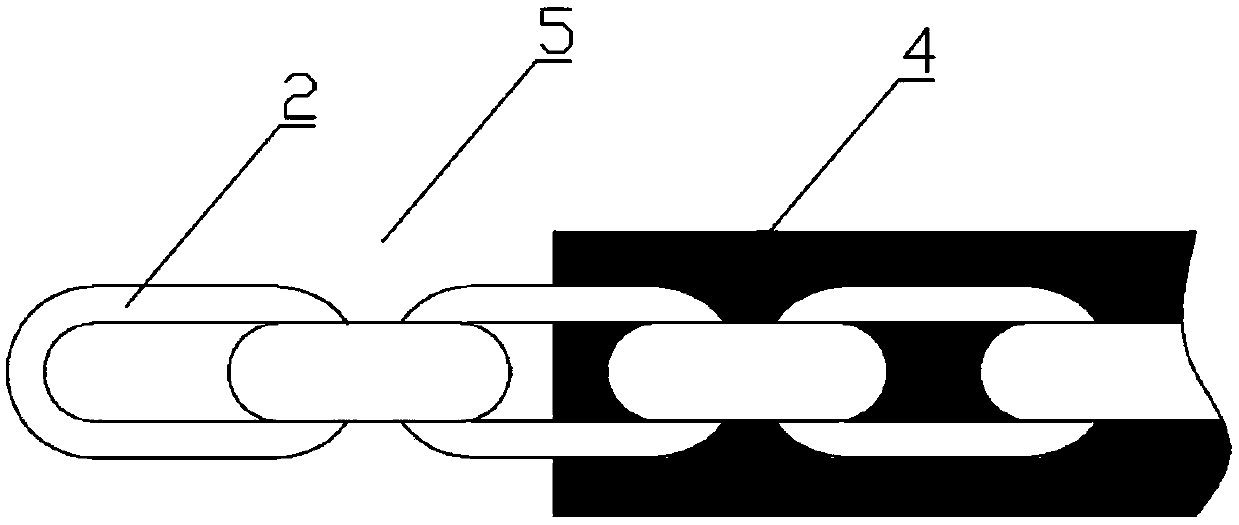

[0049] The multi-channel temperature control step is four-channel temperature control, the four-channel temperature control in the four channels includes a main channel and three auxiliary channels, and the cross-sectional shapes of the three sections of the auxiliary channels are as follows: Figure 5 As shown, the main channel forms an initial wrapping effect on the anchor chain, and the three auxiliary channels wrap the anchor chain passing through the main channel from three sections in all directions.

Embodiment 3

[0051] The multi-channel temperature control step is three-channel temperature control, and the three-channel temperature control of the three channels includes a main channel and two auxiliary channels, and the cross-sectional shapes of the two sections of the auxiliary channel are as follows: Image 6 As shown, the main channel forms an initial wrapping effect on the anchor chain, and the two auxiliary channels respectively wrap the anchor chain passing through the main channel from two sections.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap