Design and preparation method for customized fixing support used after repair of finger flexor tendon injuries

An injury repair and flexor tendon technology, applied in the field of medical devices, can solve the problems of 3D printing without considering materials and performance, not disclosing the three-dimensional reconstruction method of the affected area, and not disclosing the brace design method, etc., so as to achieve good fit and wear. Convenient, shape-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

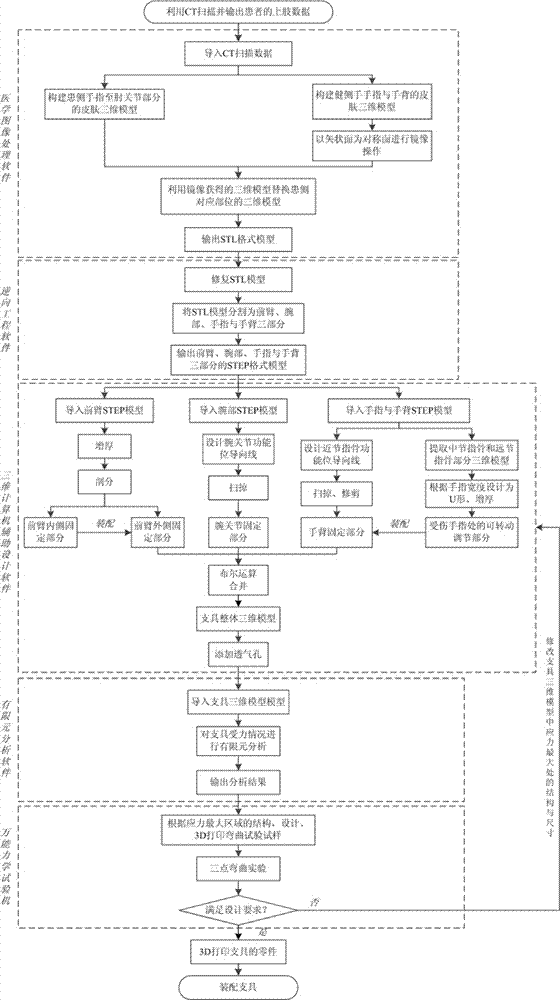

[0077] The present invention scans the affected side and the arm of the healthy side of the patient through CT, uses the scanned data to reconstruct the three-dimensional skin model from the elbow joint to the finger of the affected side, and the three-dimensional skin model of the finger and the back of the hand on the healthy side, and the three-dimensional model of the skin on the healthy side Mirror the sagittal plane as the plane of symmetry. The 3D skin model obtained by mirroring is used to replace the 3D skin model of the injured finger and the back of the hand on the affected side, and merged with the forearm of the affected side to form a new 3D skin model of the arm. Based on the combined 3D model, a customized fixed brace is designed. The designed brace was subjected to finite element analysis and three-point bending experiments. After the design results met the mechanical performance requirements, the brace was fabricated and assembled by 3D printing. The process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com