Wire winding device and control method thereof

A wire coiling and coiling technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the problems of too many coils on the coiling roll, poor rotation of the manual coiling coil, and chaotic wiring, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

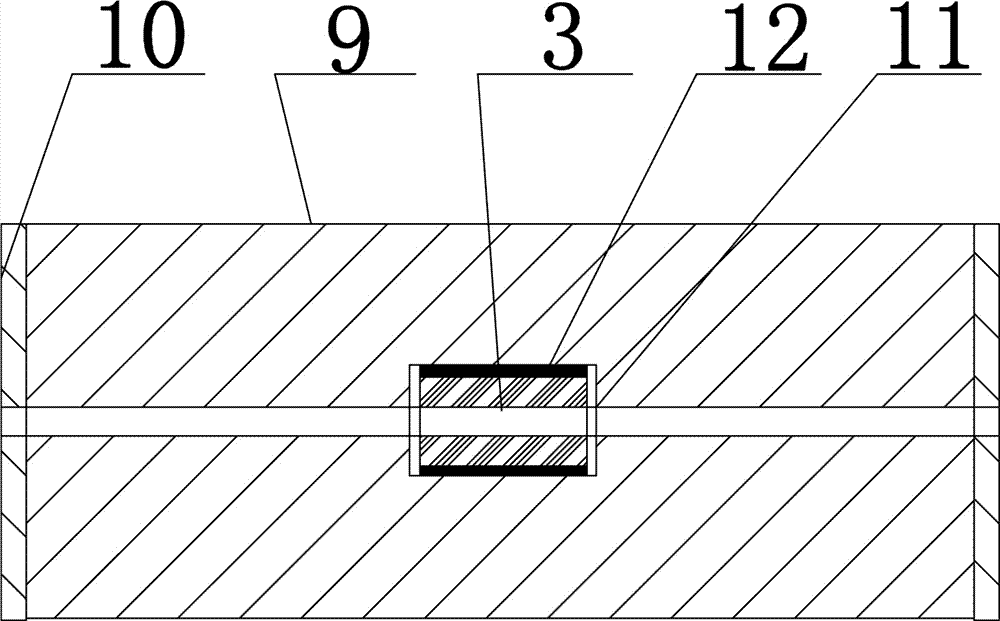

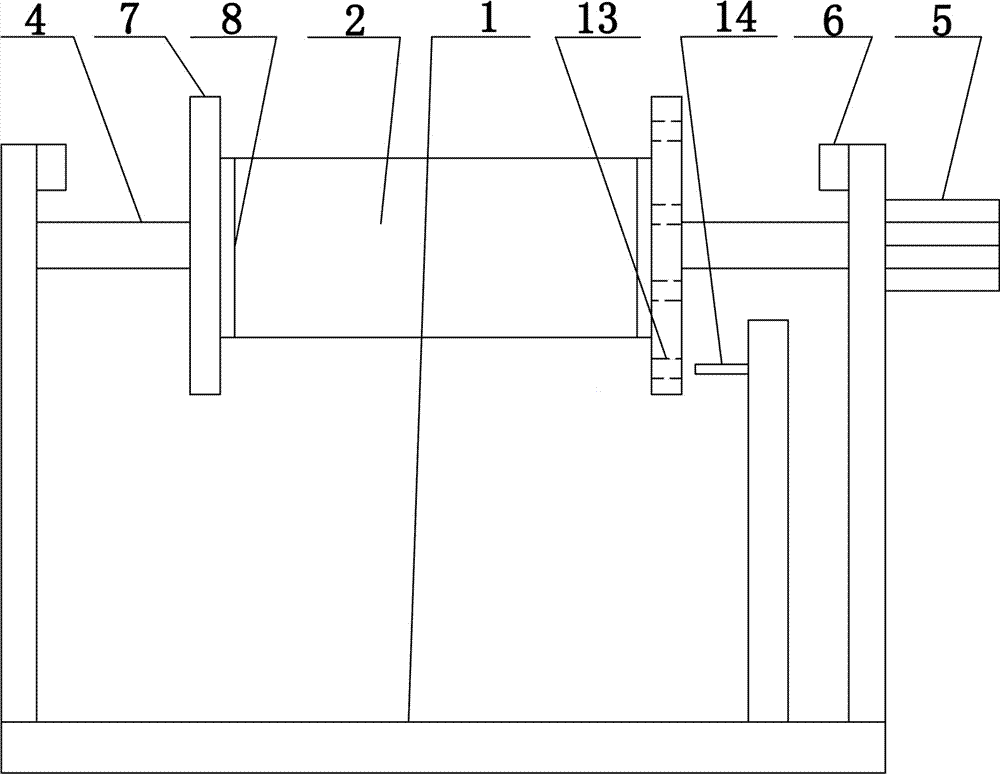

[0027] As shown in the figure, the present invention relates to a wire winding device, which includes a workbench 1, on which a winding roller 2 is arranged, and a rotating nut 3 is arranged inside the winding roller 2, and the rotating nut 3 is set on the outside of the screw 4, and the screw 4 is set on the output shaft of the motor 5; the workbench 1 at both ends of the winding roller 2 is provided with a sensing mechanism 6, and the sensing mechanism 6 is connected to the controller , the controller is connected to the motor 5 .

[0028] In the present invention, the overall device is arranged on the workbench 1, and the workbench 1 can be an elevated platform provided separately, or can be an ordinary horizontal plane.

[0029] In the present invention, the winding roller 2 is sleeved on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com