Quick disassembly and assembly type replacement trolley for filling machine

A filling machine, detachable technology, applied in the field of replacement carts for filling machines, can solve problems such as affecting product quality, complicated disassembly of parts, reducing production efficiency, etc., to achieve excellent market prospects, and improve the production efficiency of enterprises. The effect of filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

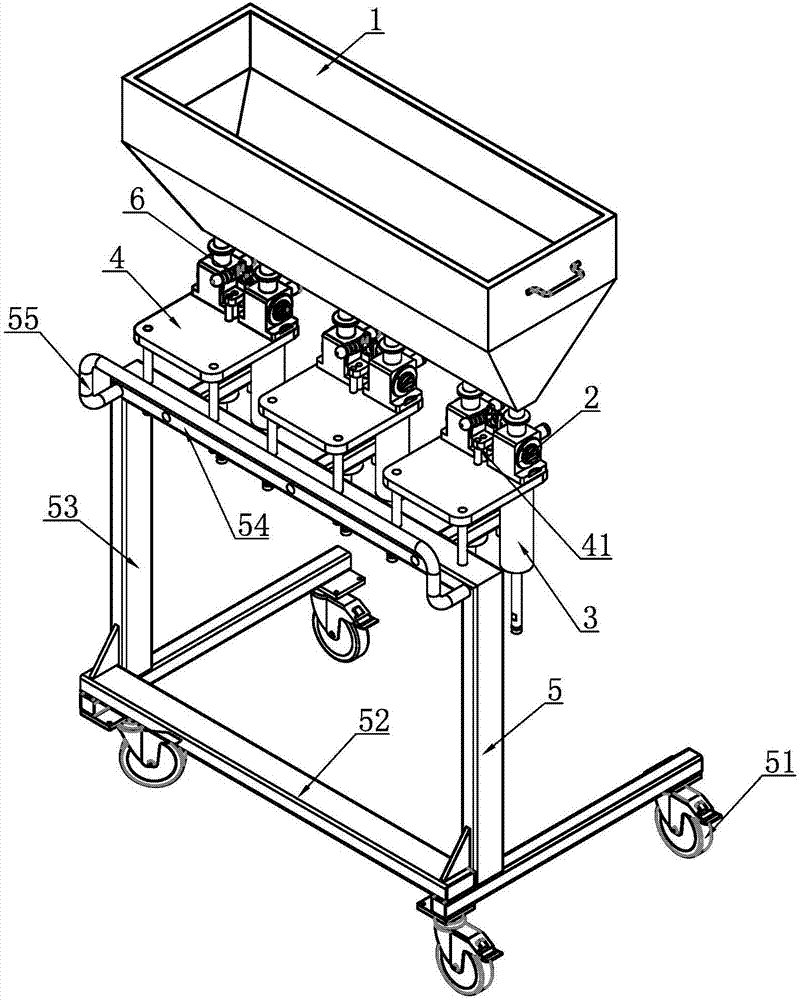

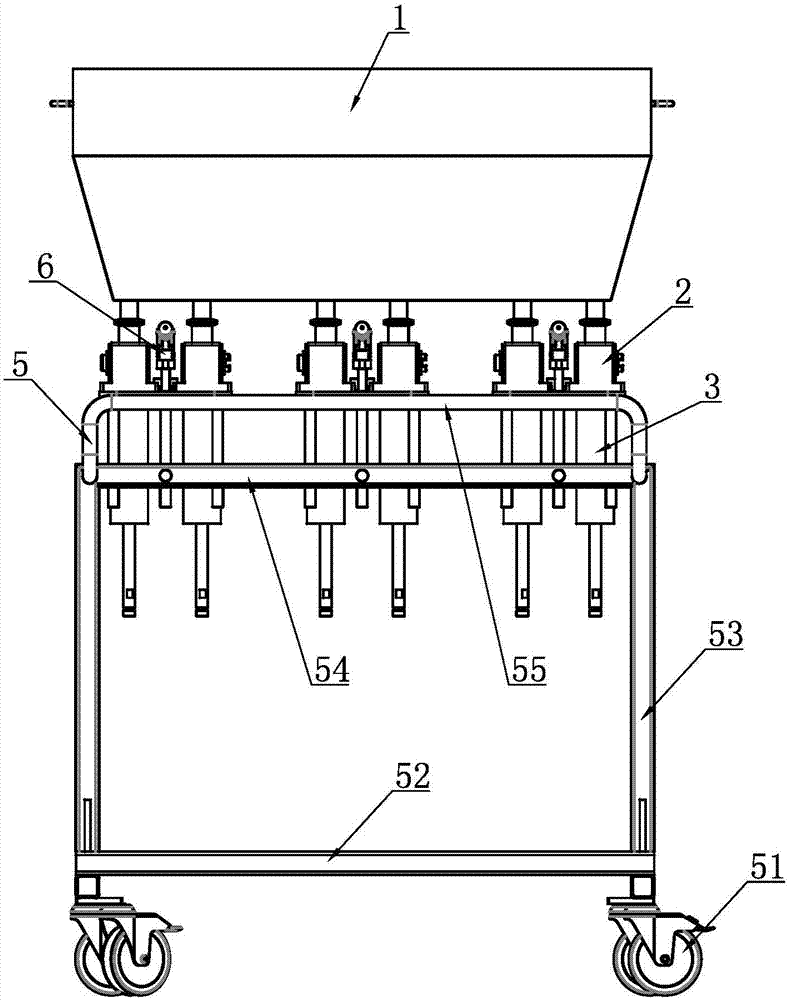

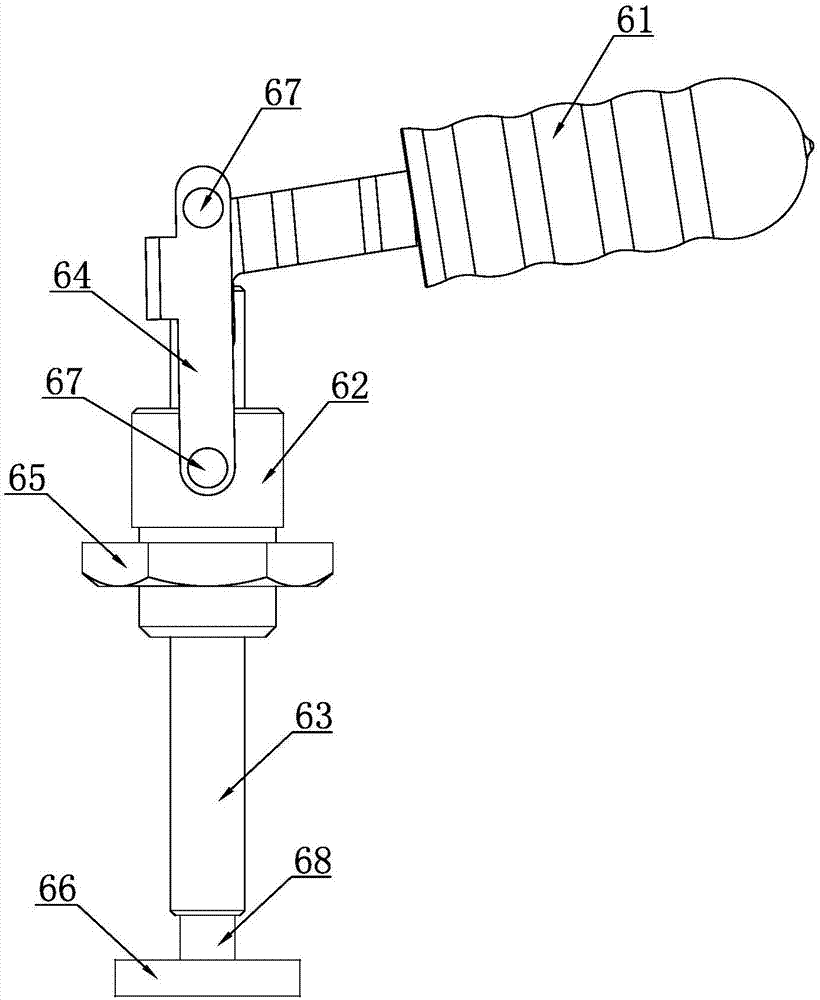

[0026] A replacement cart for a quick-release filling machine, such as Figure 1 to Figure 7 As shown, it includes a material box 1, a three-way valve 2, a piston cylinder 3, a connecting plate 4, a cart frame 5 and a fixing fixture 6, the three-way valve 2 is arranged between the material box 1 and the piston cylinder 3, and the material box 1 The discharge port is connected to the upper opening of the three-way valve 2, the upper end of the storage chamber of the piston cylinder 3 is connected to the lower opening of the three-way valve 2, the side opening of the three-way valve 2 is connected to the filling head, and the cart frame 5 comprises caster 51, base 52, support column 53, upper support plate 54 and handle 55, and caster 51 is fixedly installed on the lower end of base 52, and support column 53 is fixedly installed on the upper end of base 52, and upper support plate 54 is fixedly installed on support column 53, the connecting plate 4 is horizontally fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com