Patents

Literature

34results about How to "Reduce damage costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

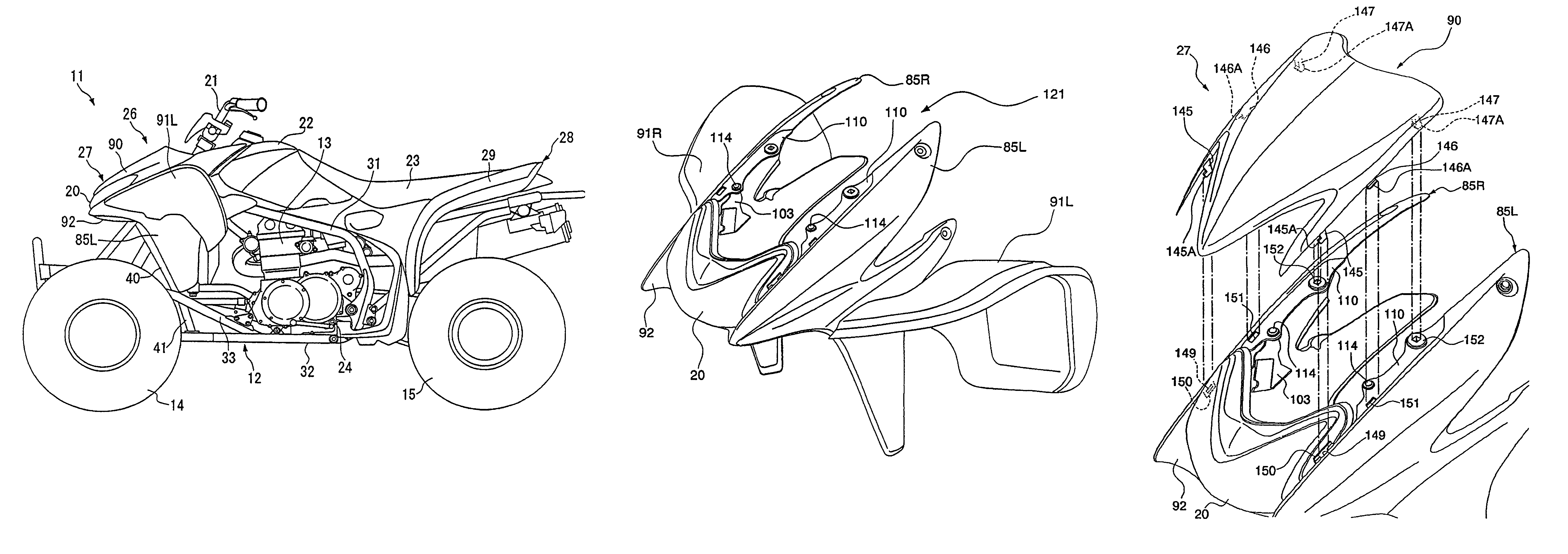

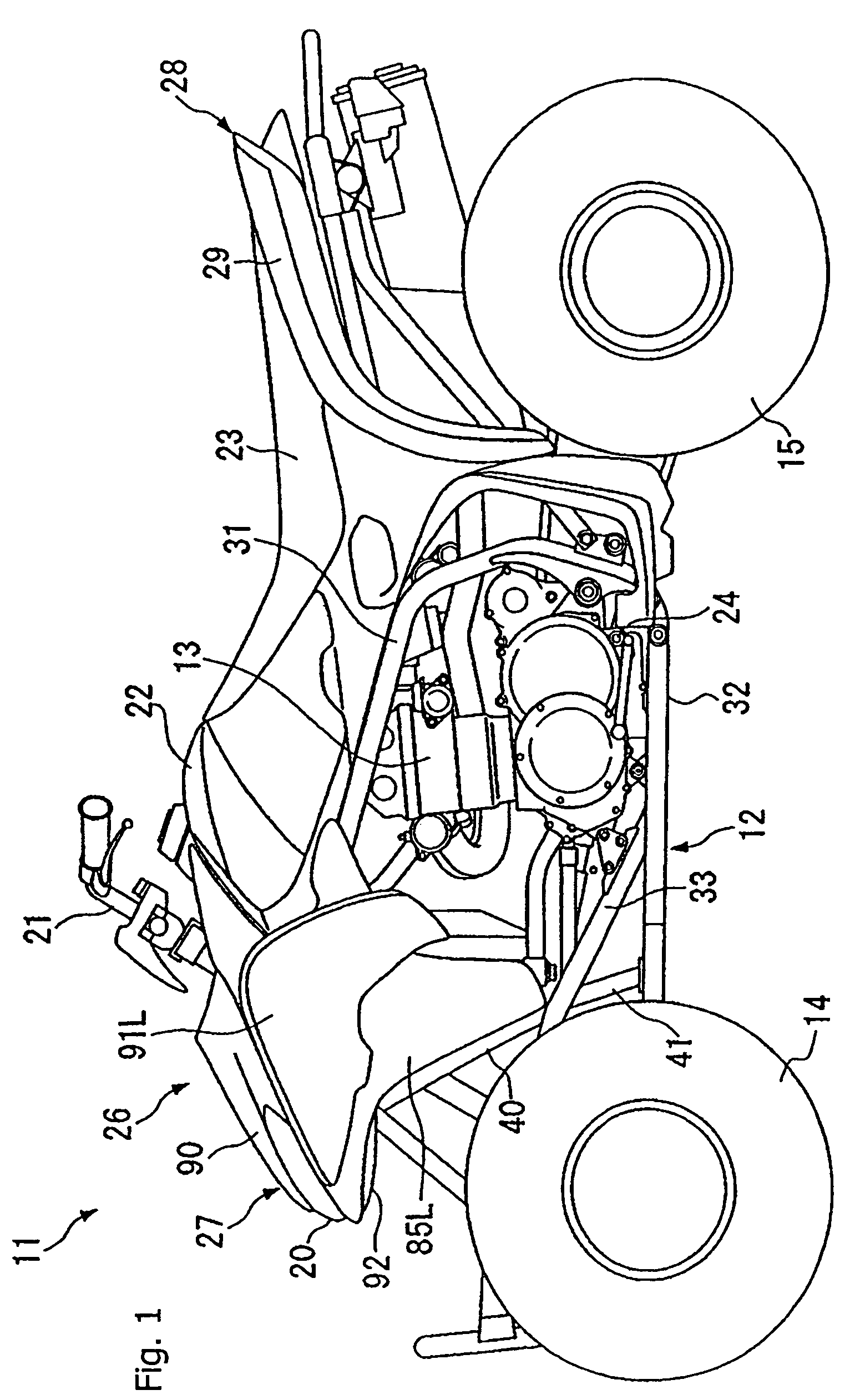

Front end components for a saddle-type vehicle

ActiveUS7231996B2Reduce damage costsReduce manufacturing costSuperstructure subunitsWeather guardsFront coverAerospace engineering

A front cover structure for a saddle-type vehicle, in which the cost of replacement in damage and the manufacturing cost can be reduced and a degree of the freedom of design appearance can be enhanced. In the front cover structure for a saddle-type vehicle in which a front cover 27 is provided so that it encloses a headlight 20 in the center of the front of the body, the front cover 27 is divided into a center cover for placement covering a top central front portion of the vehicle body, a left shroud 85L provided for placement on the left side of the center cover, and a right shroud 85R provided for placement on the right side of the center cover. The left shroud 85L and the right shroud 85R are coupled via the headlight 20.

Owner:HONDA MOTOR CO LTD

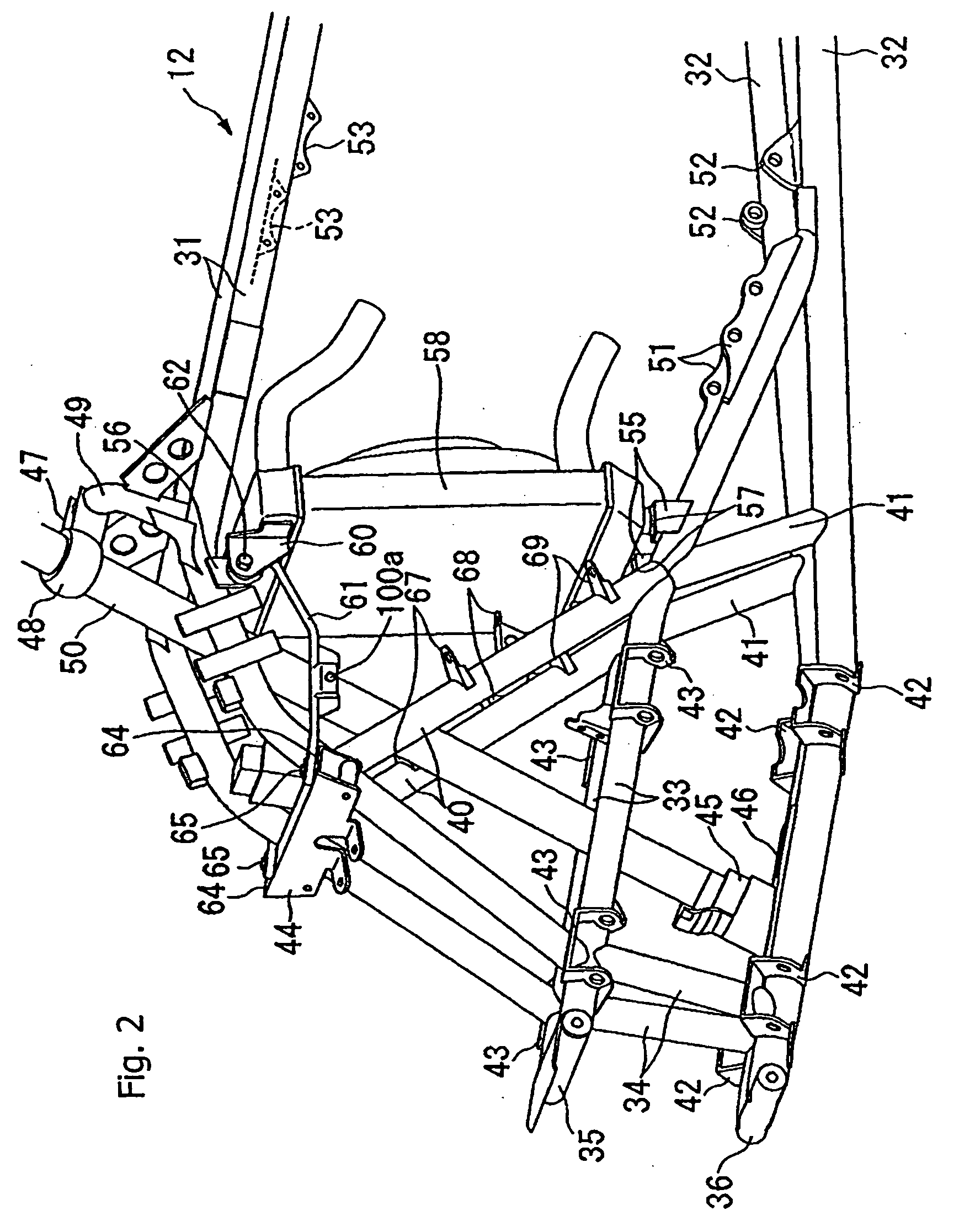

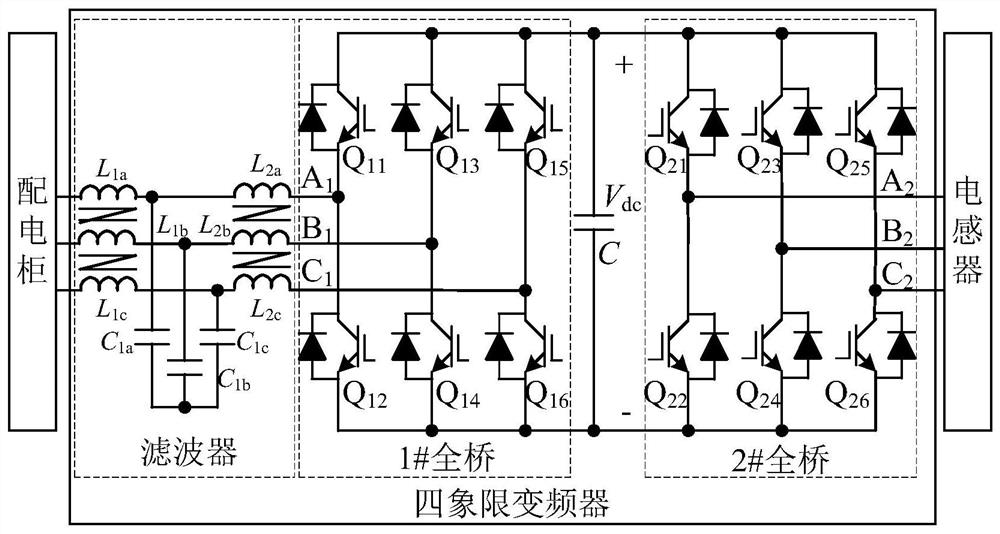

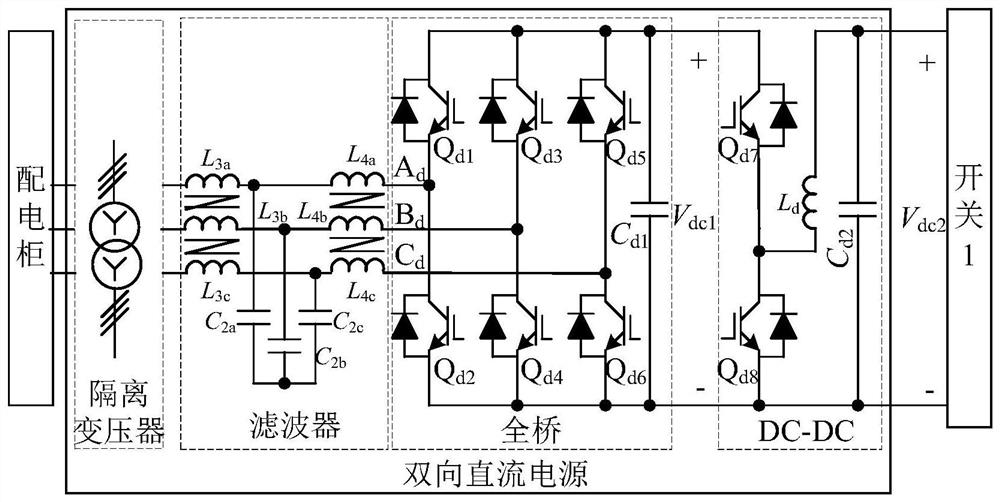

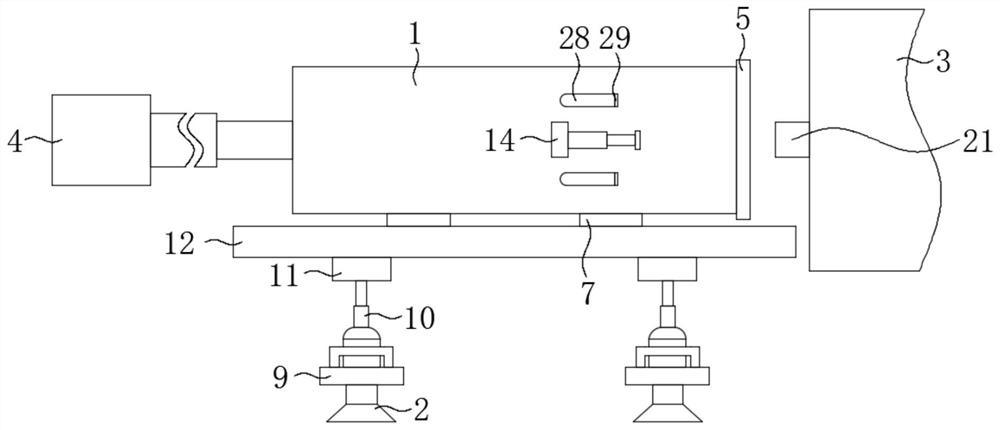

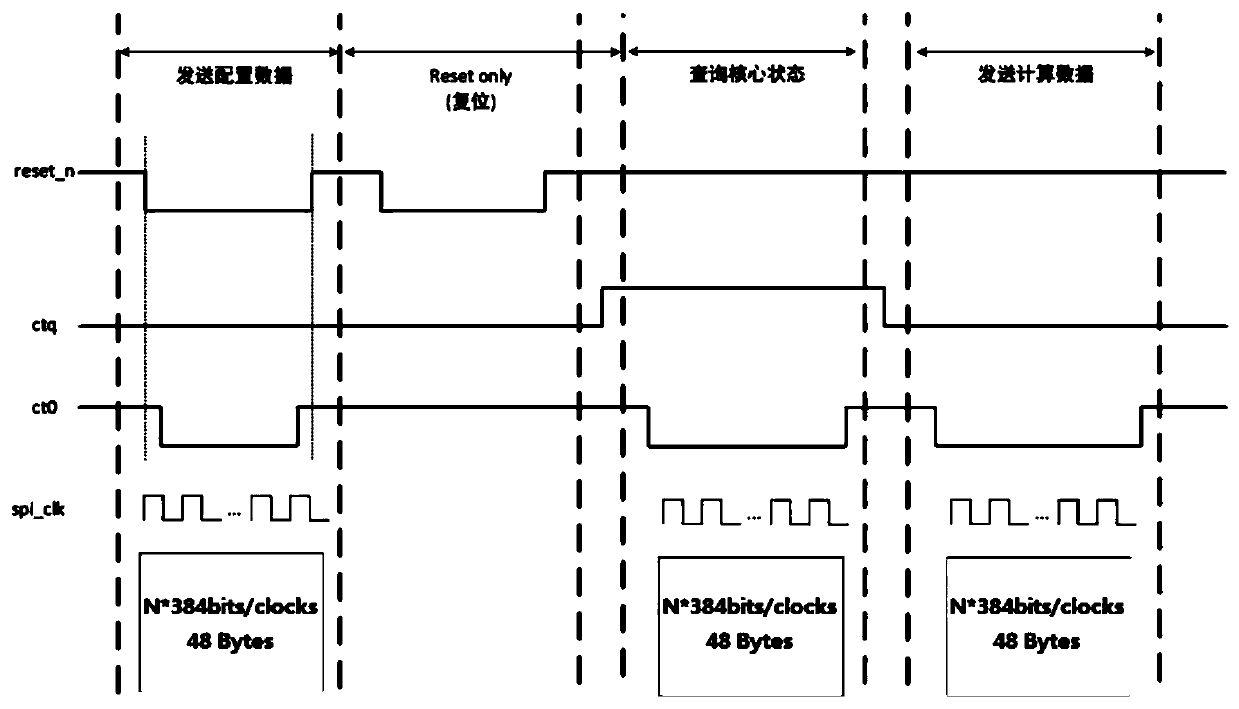

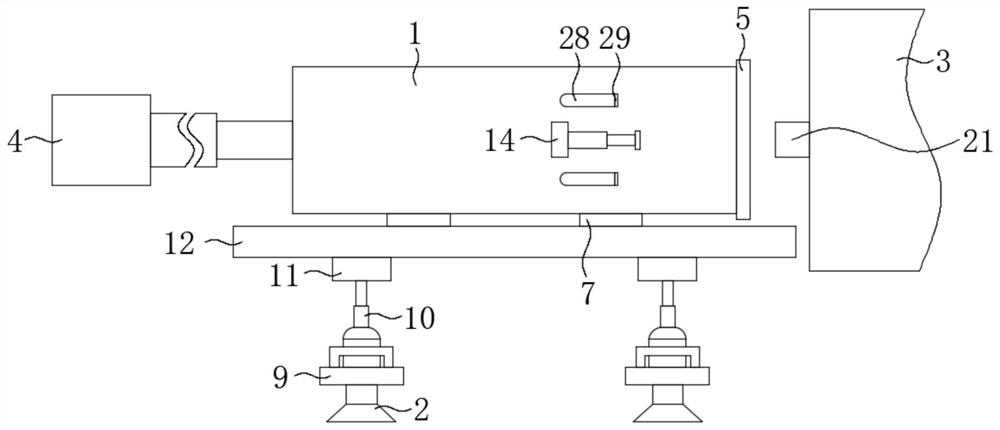

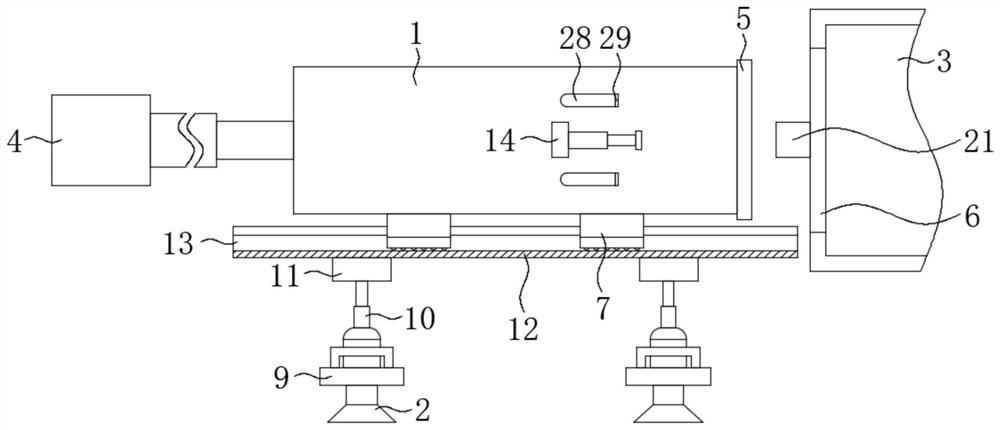

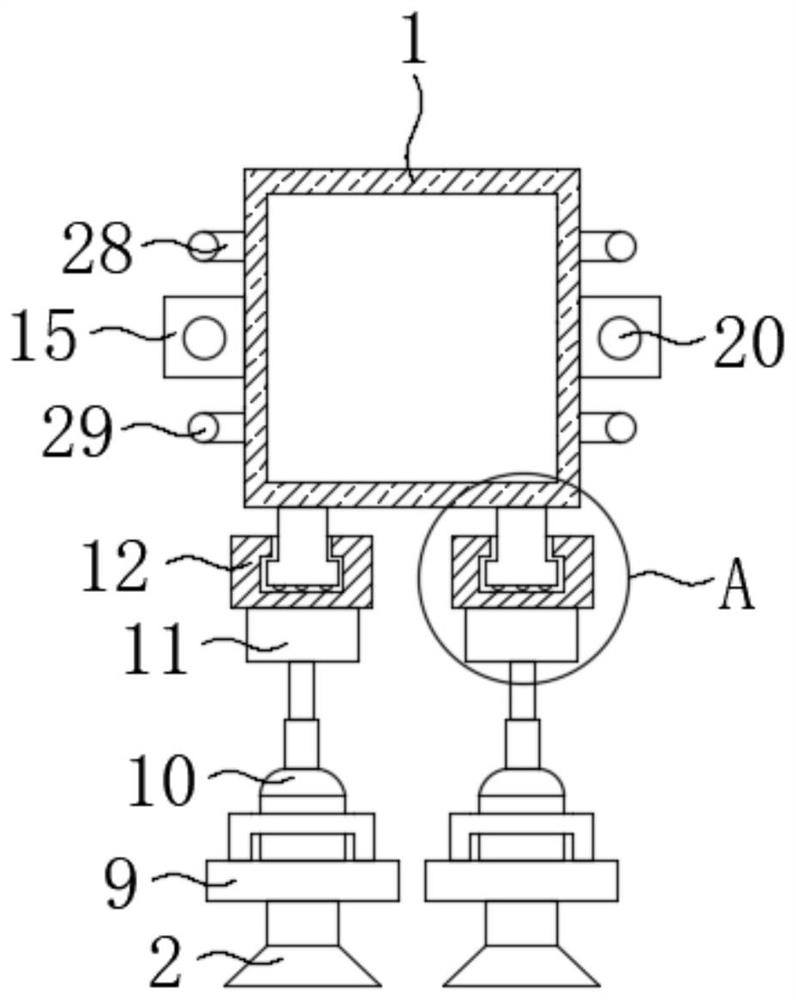

High-temperature high-speed starter generator system test system and test method thereof

ActiveCN111766515AGuaranteed to workHigh damage costEngine testingDynamo-electric machine testingStarter generatorTransverter

The invention discloses a high-temperature high-speed starter generator system test system and a test method thereof. A tested starter generator is placed in a high-temperature environment box; duringpower generation testing, an input rotating speed of the tested starter generator is controlled through a four-quadrant frequency converter, dynamic rapid loading and unloading are carried out through a program control load box to realize dynamic performance testing, and steady-state and service life testing is carried out by making a bidirectional direct-current power supply feed back power gridenergy to simulate a steady-state load.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD +1

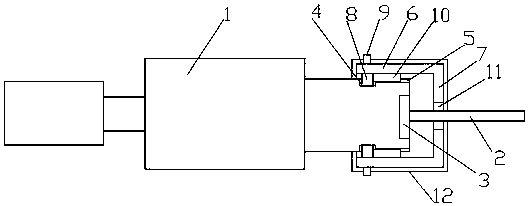

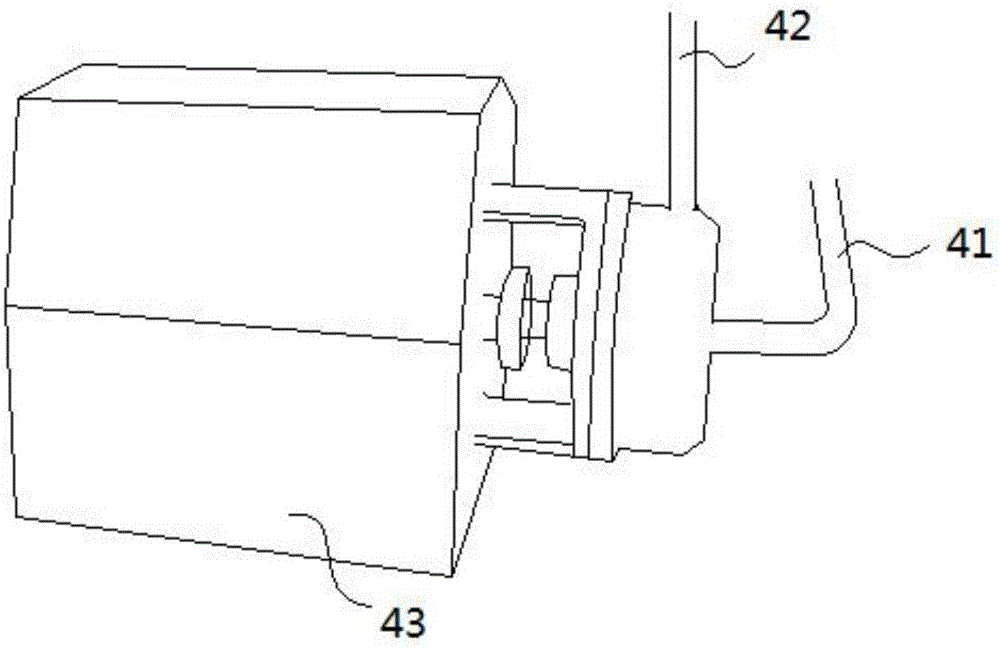

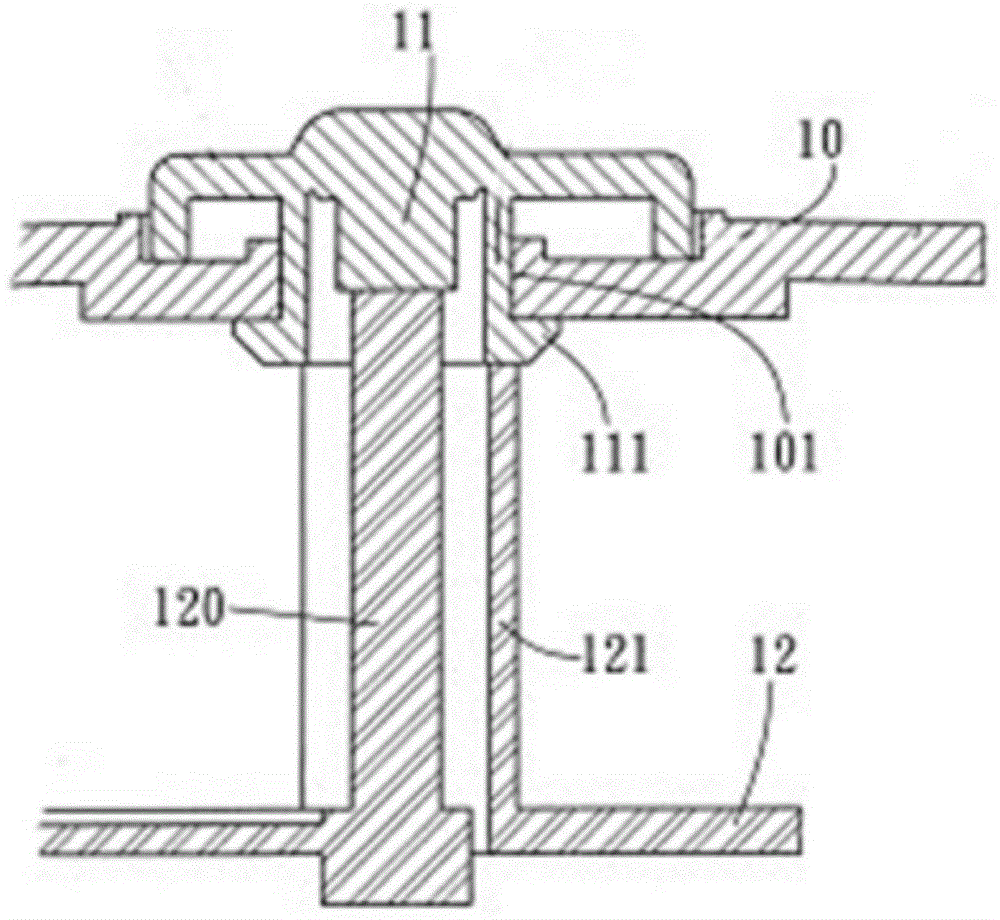

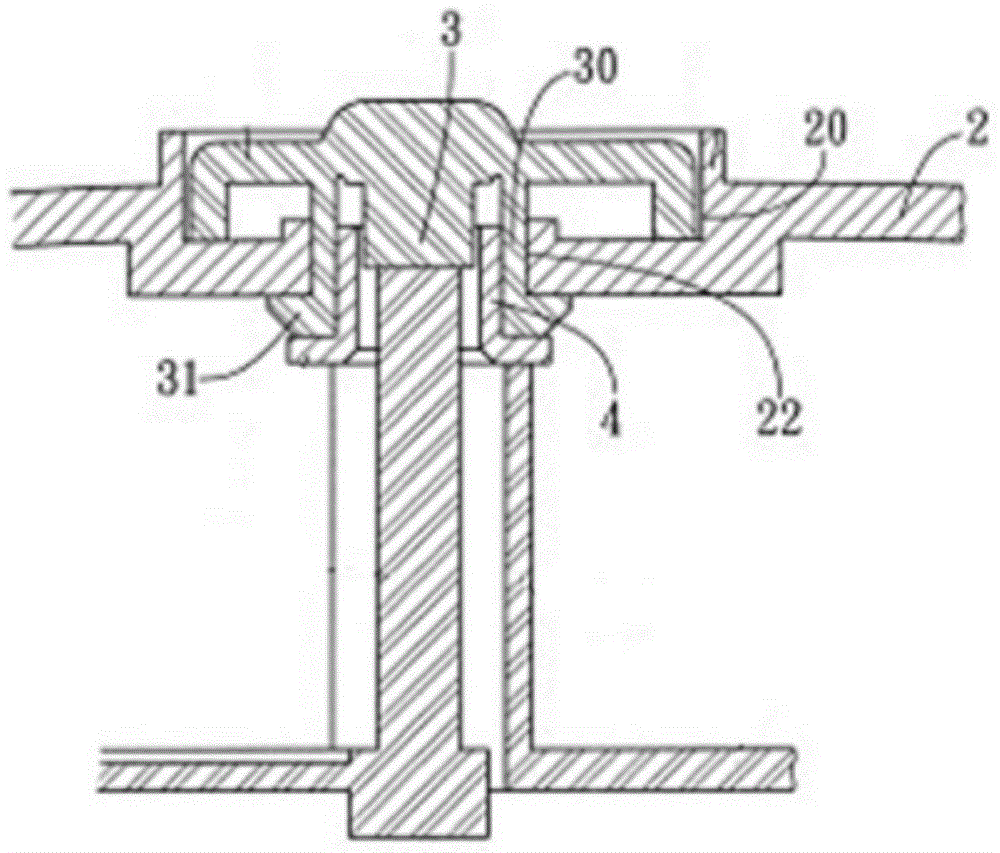

Detachable pressure sensor

PendingCN108106756AEasy to disassembleSimple structureForce measurementFluid pressure measurementDamage costEngineering

The invention discloses a detachable pressure sensor, which comprises a pressure sensor body and a wire connector. A chip arranged at one end of the pressure sensor body is correspondingly connected with the wire connector. A plurality of embedding grooves are correspondingly formed in the outer surface of the connecting end of the pressure sensor body. The wire connector is correspondingly arranged on a cylindrical fixing sleeve. The sleeve wall of the cylindrical fixing sleeve is arranged at the bottom fixed end of the wire connector through a plurality of longitudinal blocking strips and two adjacent blocking strips are arranged in a clearance mode. Positioning clamping blocks are correspondingly arranged at the end parts of the inner sides of any two adjacent blocking strips. The positioning clamping blocks and the embedding grooves are arranged in a one-to-one correspondence mode. A layer of elastic sealing piece is further hermetically wrapped outside the cylindrical fixing sleeve. The detachable pressure sensor is simple in structure, convenient to mount and use, simple to disassemble, good in sealing performance, and good in connection stability. The damage cost can be effectively reduced.

Owner:苏州康姆普机械有限公司

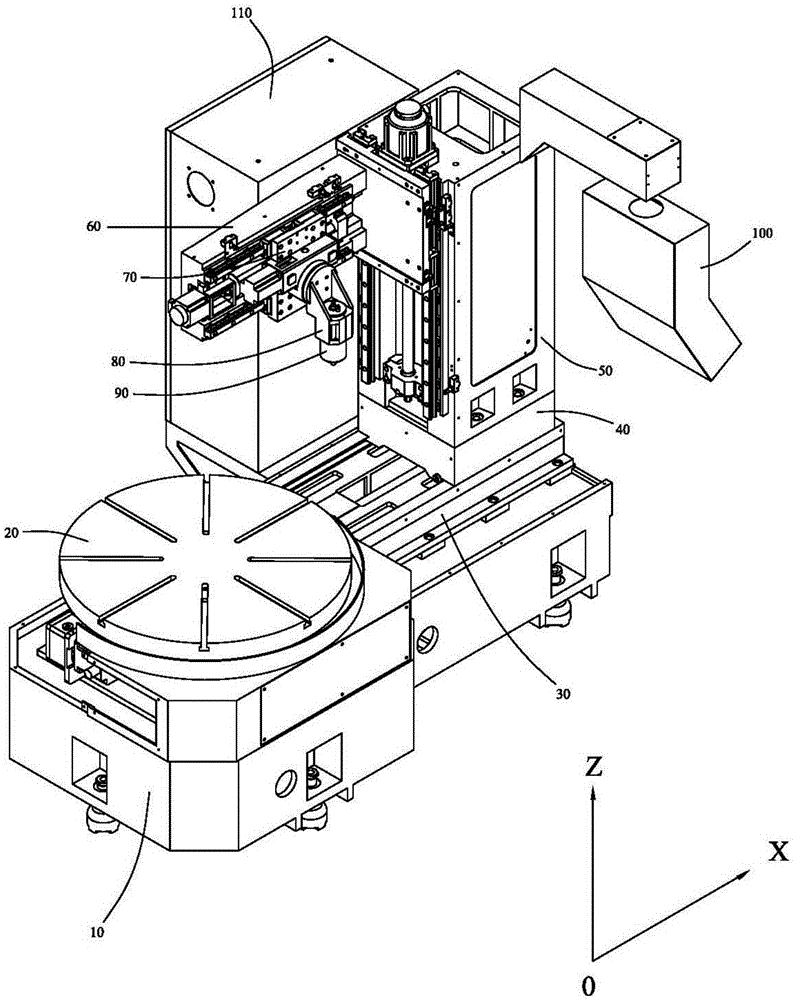

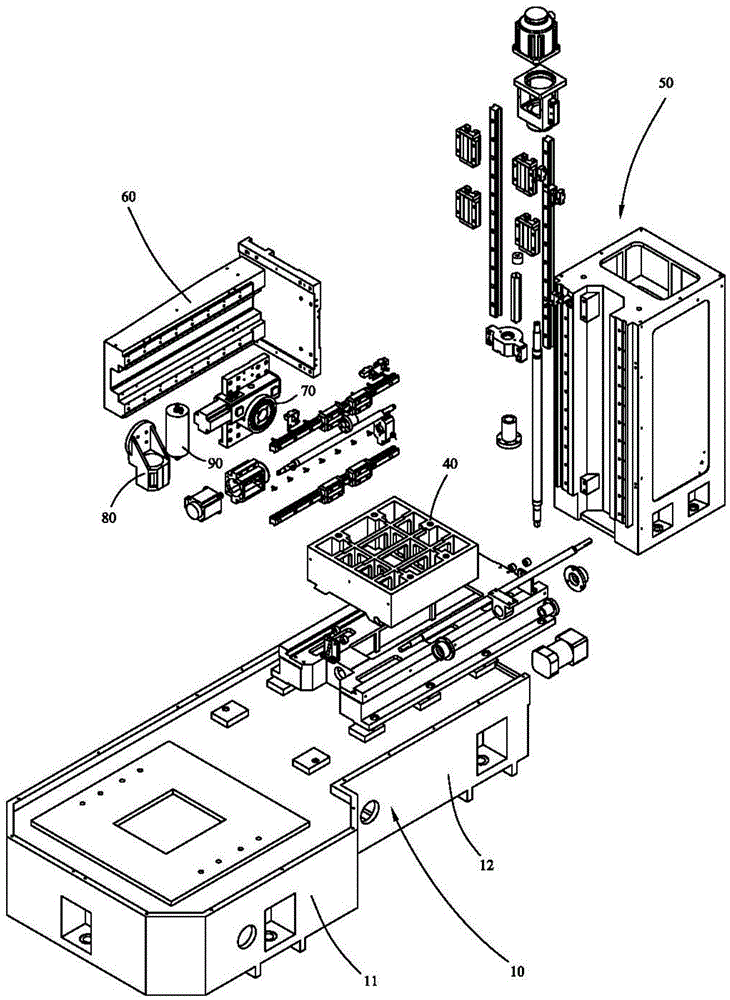

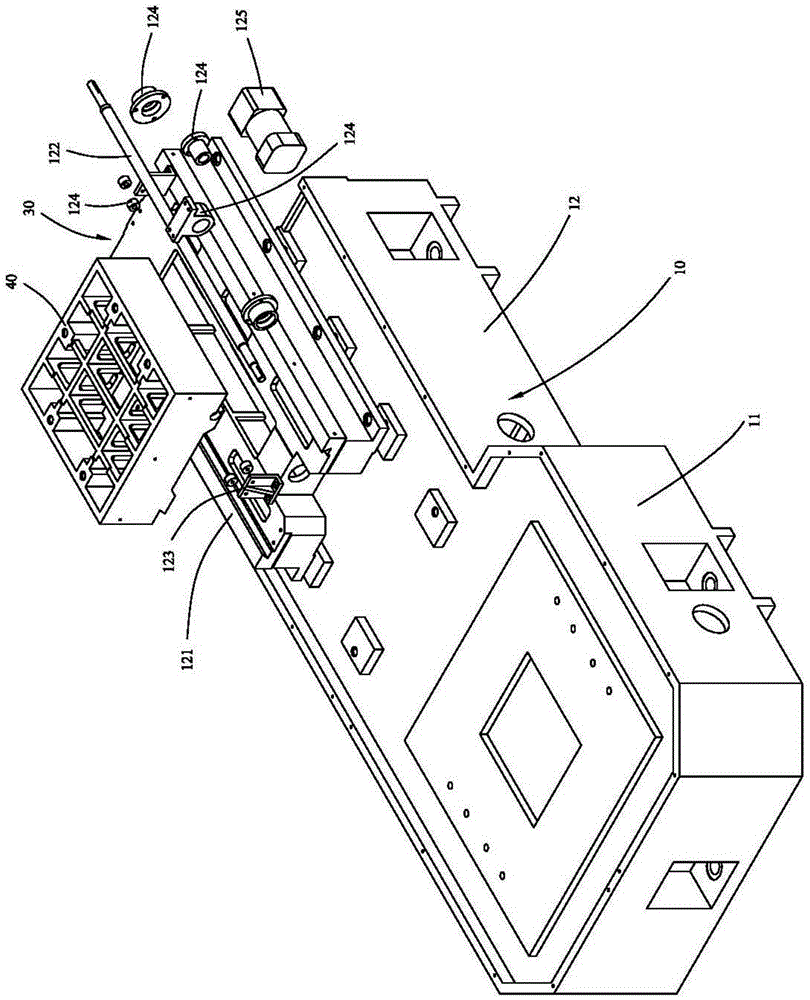

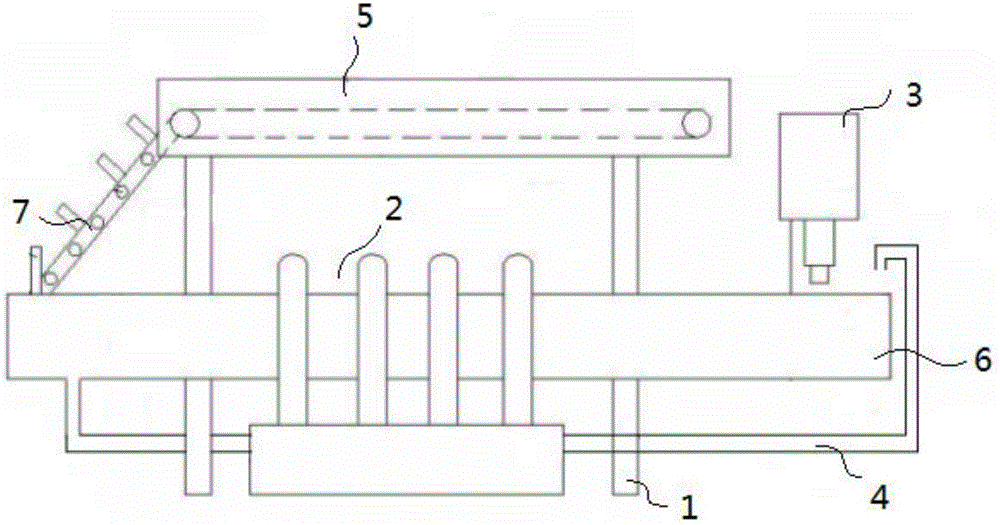

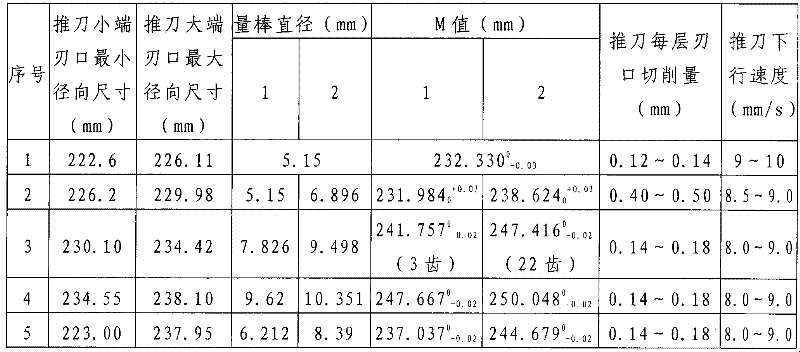

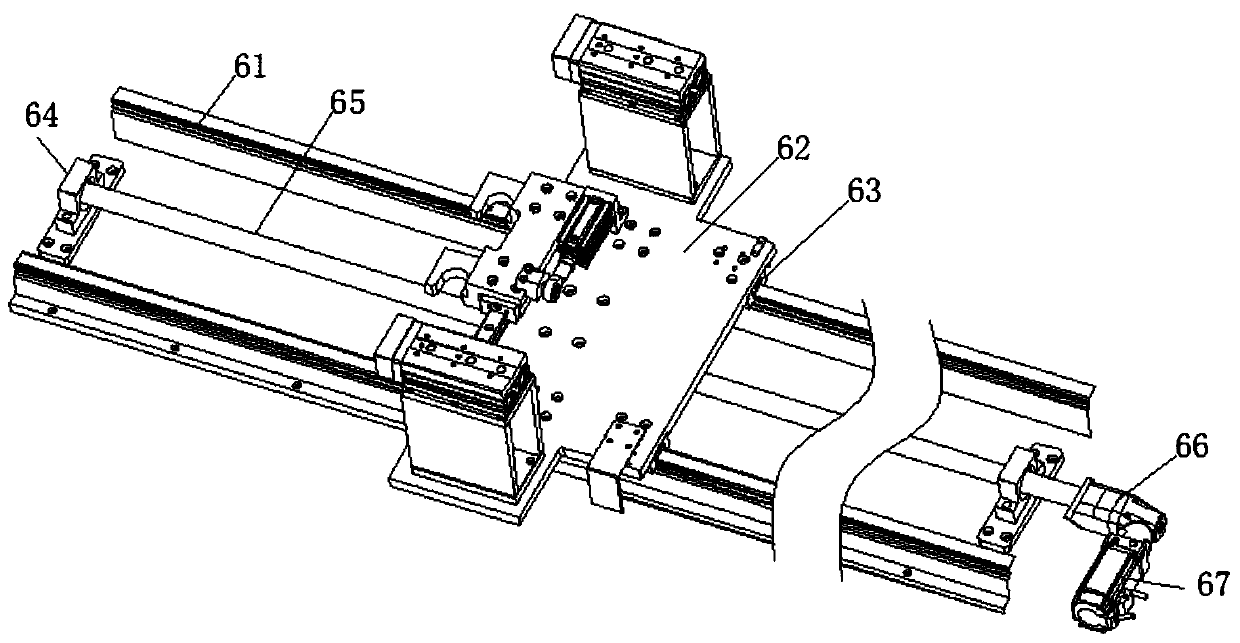

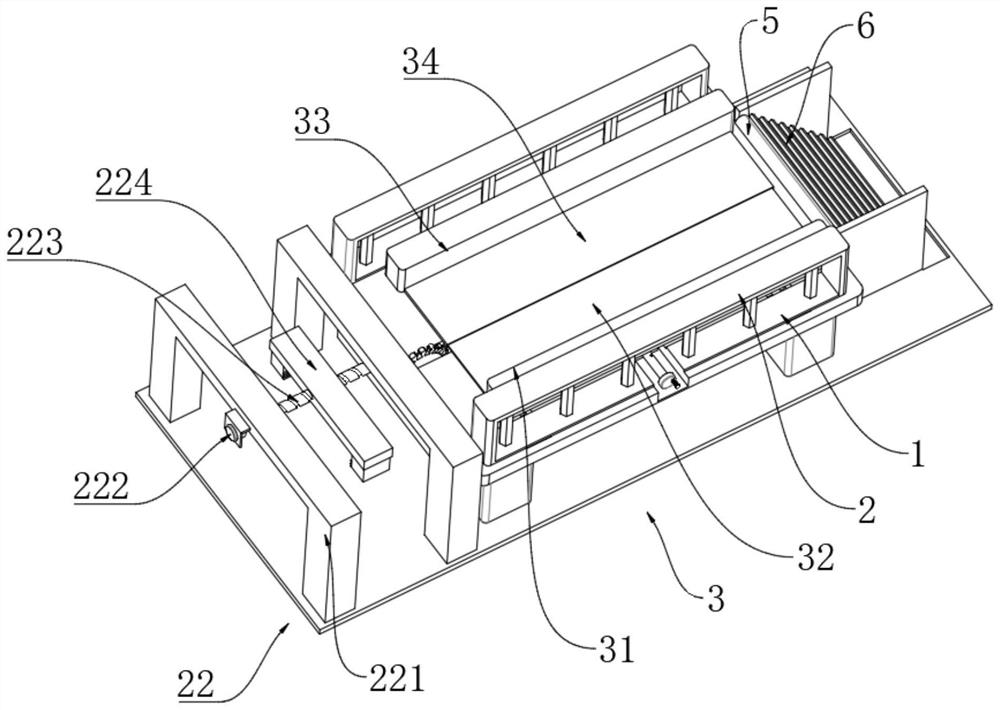

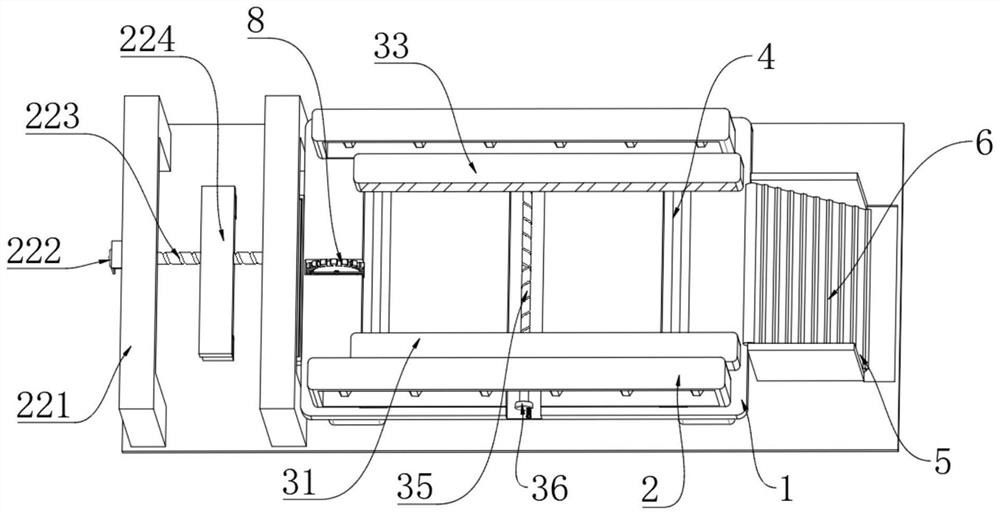

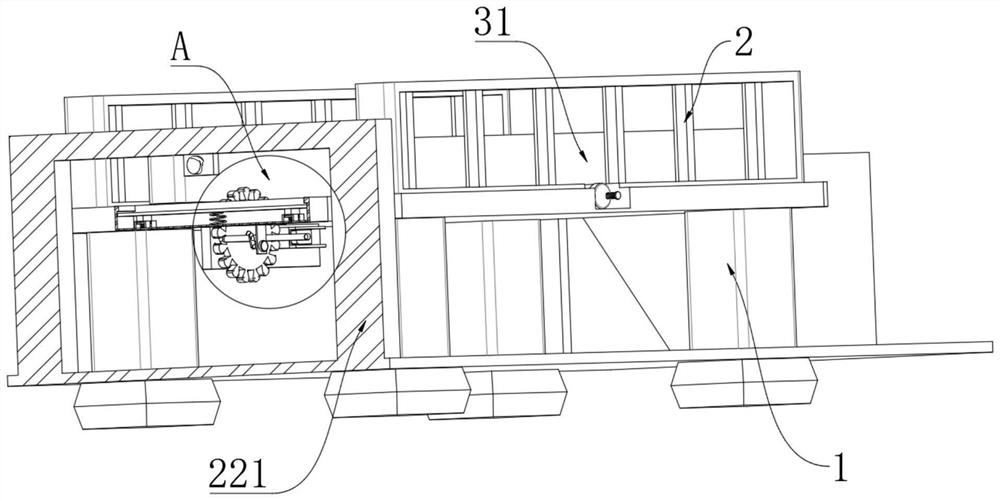

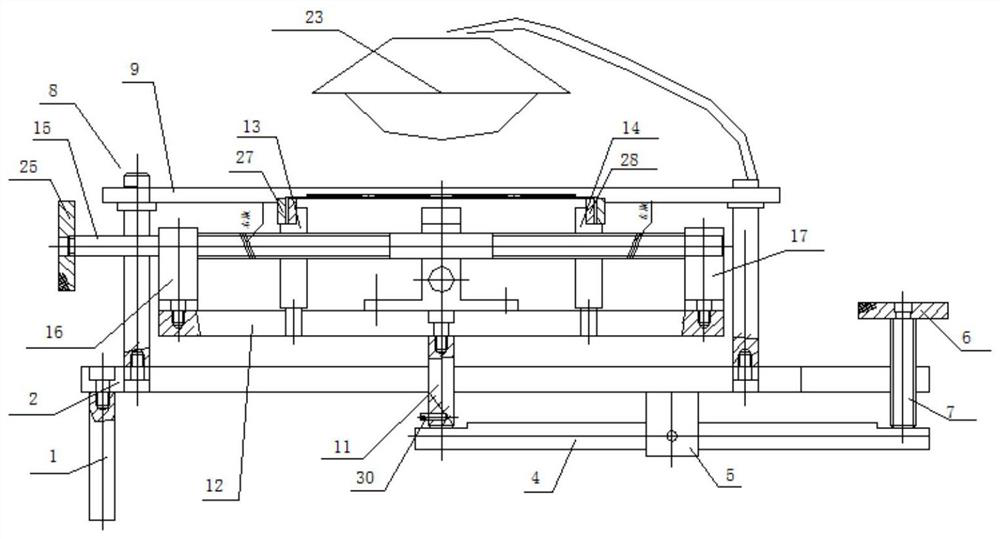

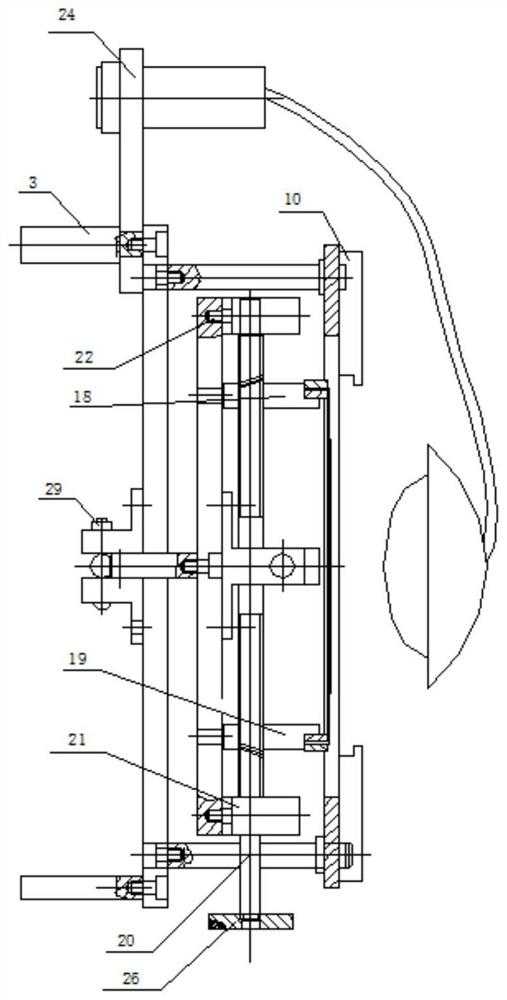

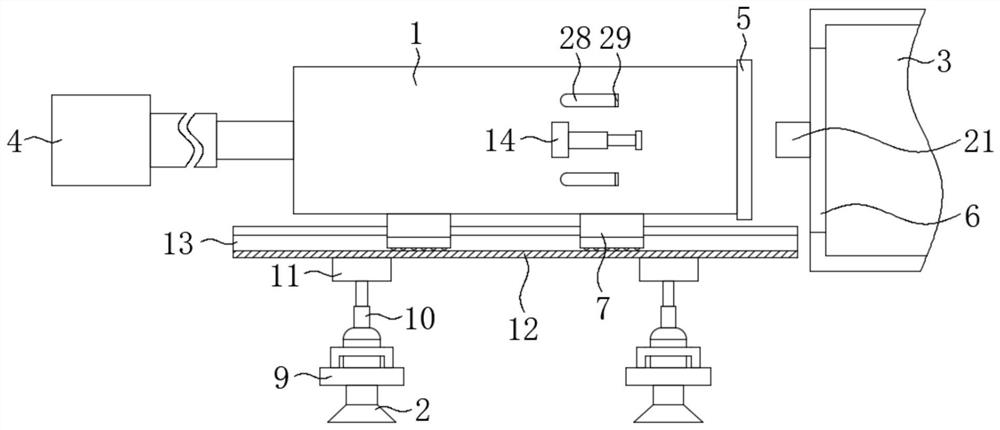

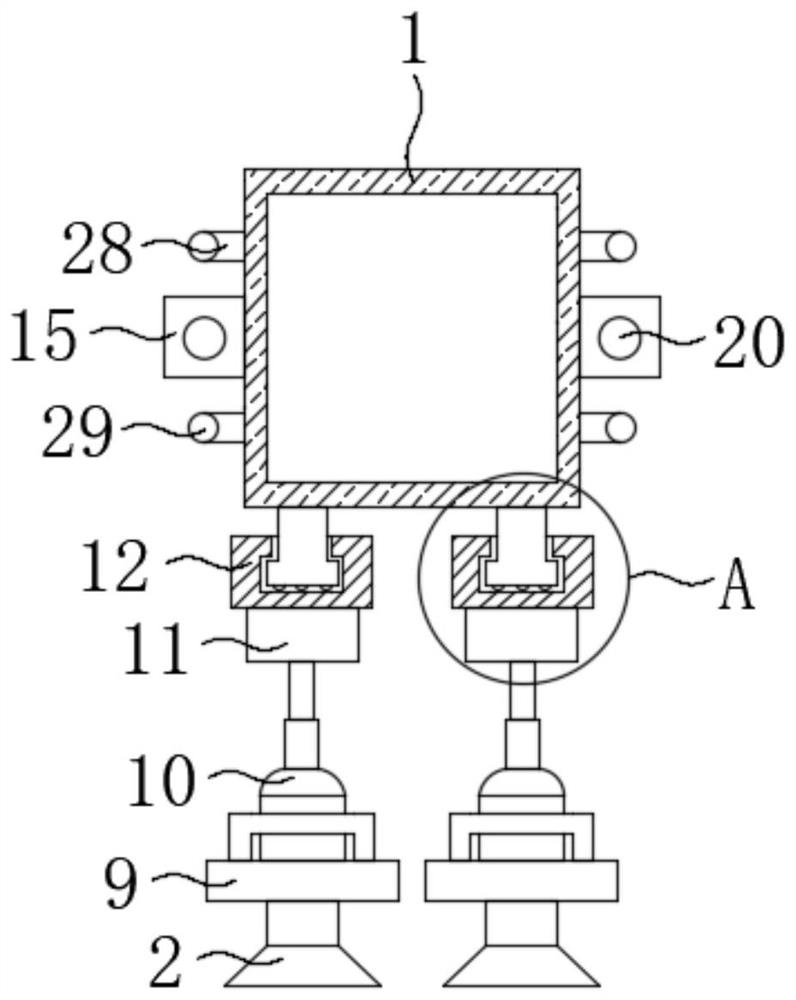

Four-shaft character carving machine for tire molds and character carving method thereof

The invention provides a four-shaft character carving machine for tire molds and a character carving method thereof. The four-shaft character carving machine comprises a base, a rotary work table located at one end of the base, a vertical column base fixed to the base in a sliding mode, a vertical column fixed to the vertical column base, a main shaft saddle fixed to one side surface of the vertical column in a sliding mode, a rotary index plate fixed to the main shaft saddle in a sliding mode, a main shaft combination base fixed to the end of the rotary index plate and an electric main shaft located in the main shaft combination base; a first transmission device is arranged on the side surface of the vertical column, a second transmission device is arranged on the main shaft saddle, the main shaft saddle is fixed to the first transmission device in a sliding mode, and the rotary index plate is fixed to the second transmission device in a sliding mode. According to the machine and the method, the transmission devices in multiple directions control the four-shaft character carving machine for the tire molds, the machining depth direction of the electric main shaft is always perpendicular to the curved surfaces of the tire molds, the cost of mold damage caused by human factors is lowered, the overall work efficiency is improved, and the qualification rate of products is increased.

Owner:群基精密工业(苏州)有限公司

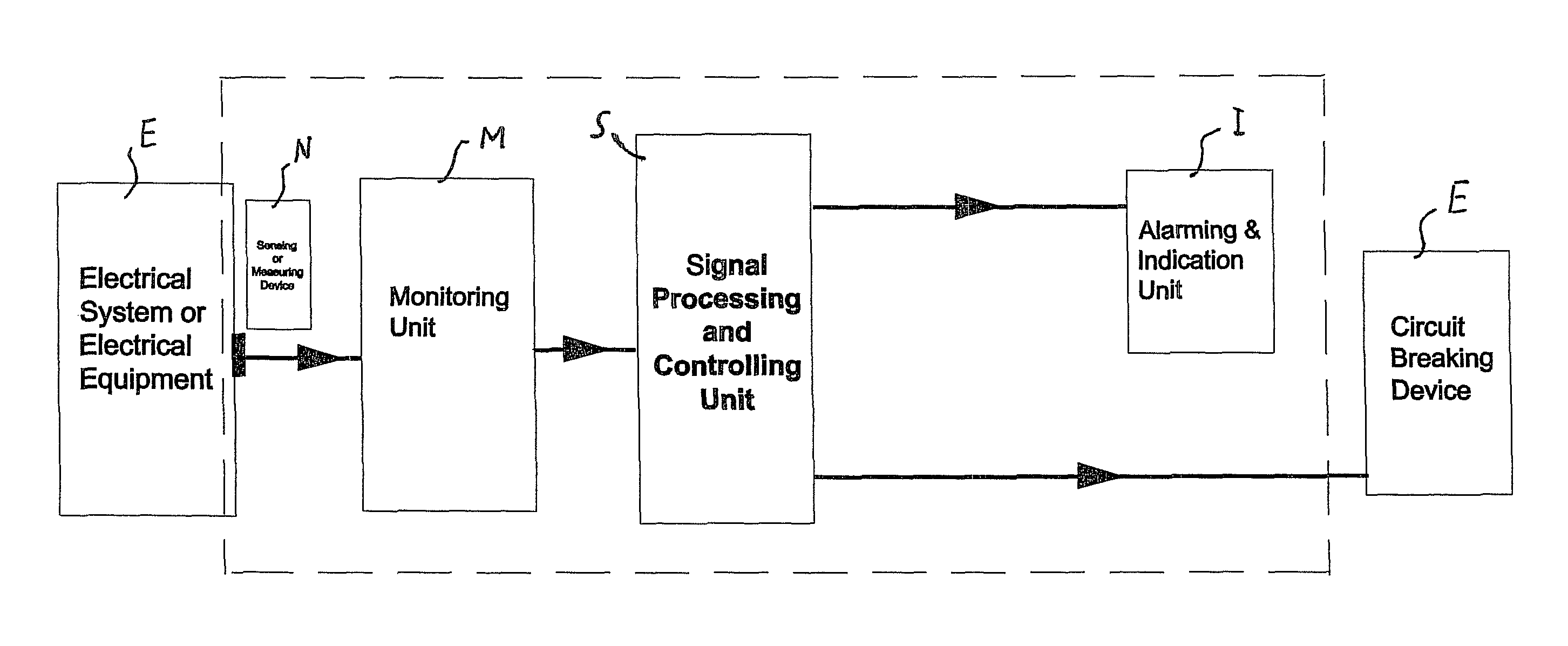

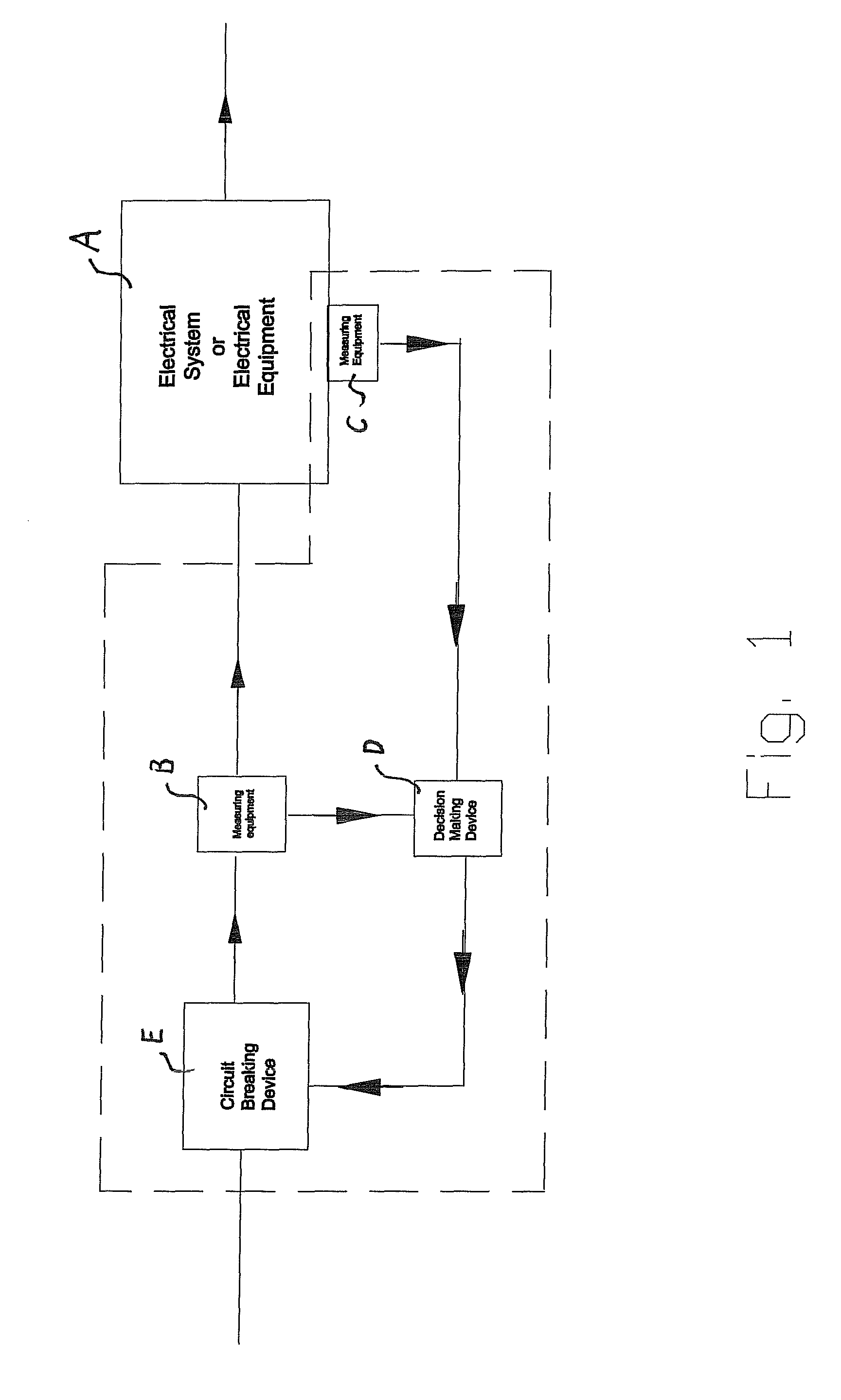

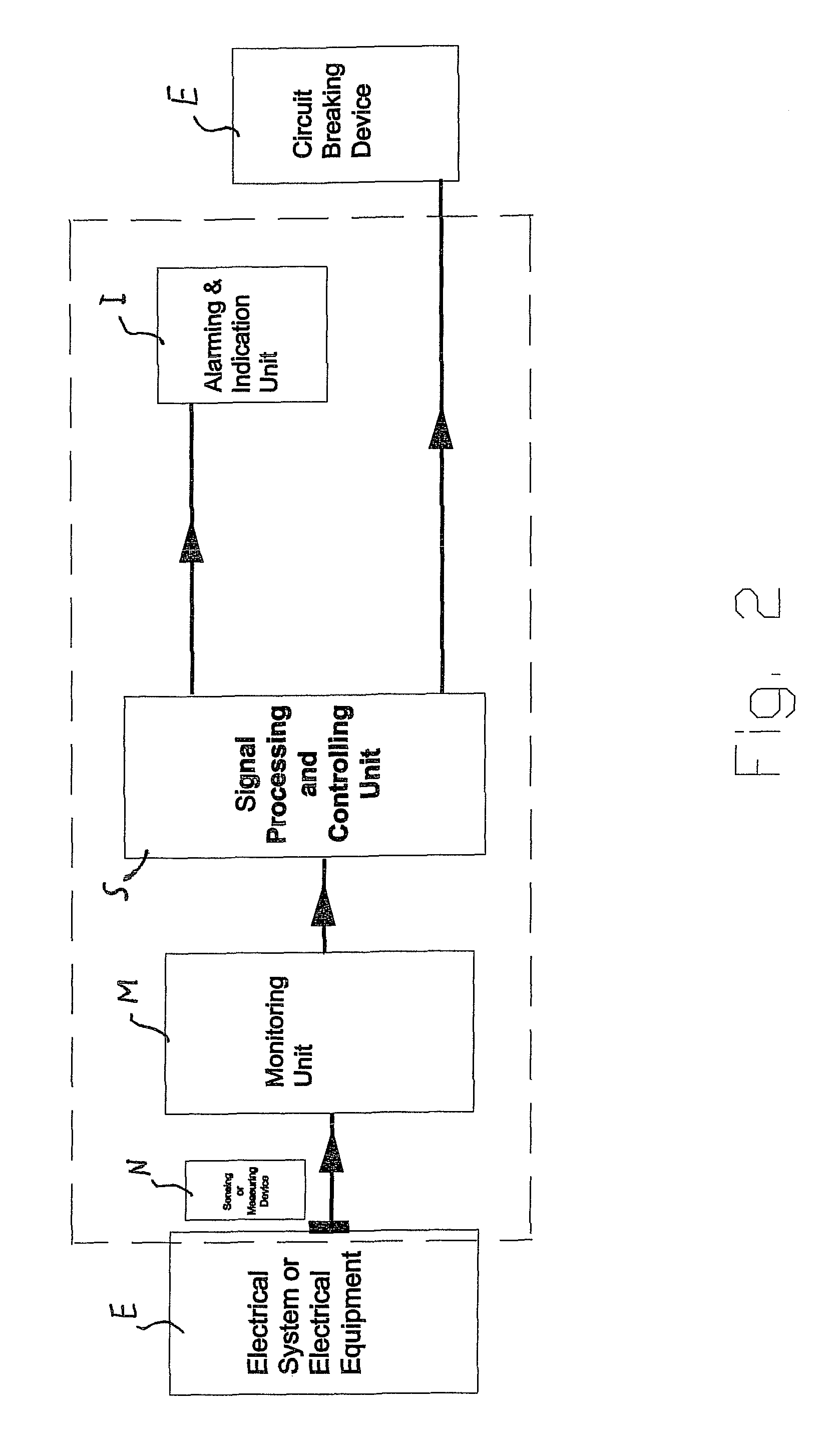

Electrical fault restricting system

InactiveUS8339755B2Reduce harmReduce damage costsEmergency protective arrangements for automatic disconnectionAlarmsElectrical FailureElectrical devices

Electrical fault restricting system for an electrical equipment and / or electrical system has a monitoring unit placed at location of interest to sense or measure electrical fault occurred with the help of sensing or measuring device which is further connected to signal processing and controlling unit which receives data collected by the monitoring unit that provides output for fault identification, alarming and controlling actions to alarming. An indication unit and command for trip signal to circuit breaking device where processed data of data collecting and processing unit are stored at data history storage. A display unit for back reference monitoring unit provides images to image receiver. A processor and controlling unit further provides processed images to an additional data history storage and display unit for future analysis of conditions where plurality of signal processing and controlling unit is inter connected with additional remote central controlling and data handling unit.

Owner:JOSHI MUKUNDLAL

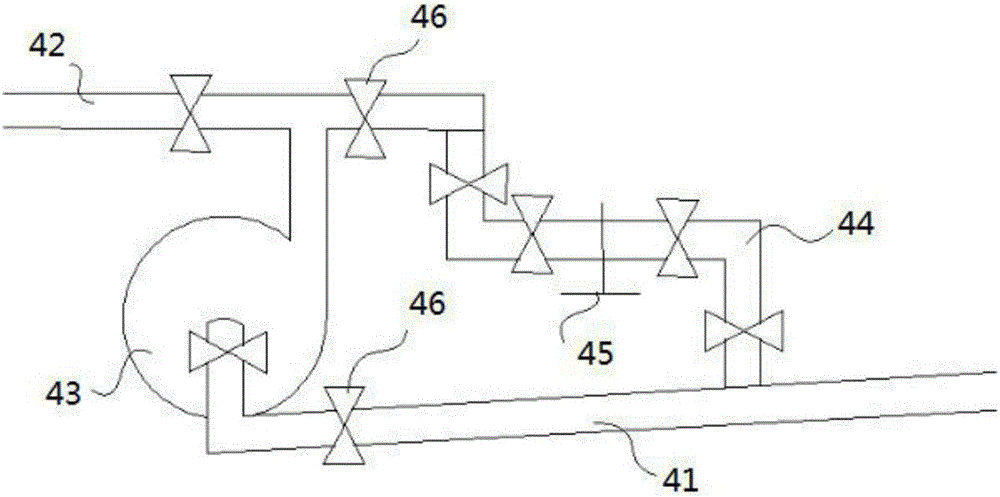

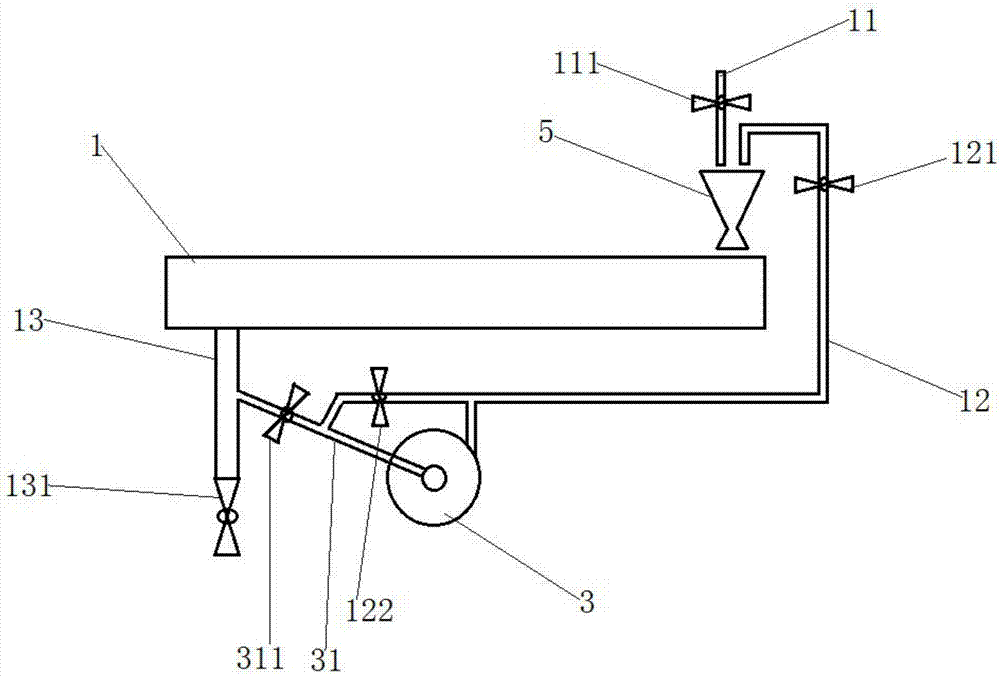

Yuba production apparatus based on slurry returning system hydraulic pressure

PendingCN106417638AAvoid damageRelieve pressureCheese manufactureFood scienceSlurryPulp and paper industry

The invention discloses a yuba production apparatus based on an adjustable slurry returning system hydraulic pressure, and belongs to the field of yuba processing. The yuba production apparatus comprises an upper layer rack and a lower layer rack, wherein a crusting system is positioned on the lower layer the rack, a drying system is positioned on the upper layer of the rack, a slurry inlet system is positioned on the front end of the crusting system, a yuba shrinkage system is positioned on the rear end of the crusting system, a slurry returning system is positioned on the lower portion of the crusting system and comprises a slurry returning pipeline, a slurry conveying pipeline and a slurry sucking pump, one end of the slurry returning pipeline is communicated to the terminal end of a crusting groove, one end of the slurry conveying pipeline is communicated to the slurry inlet end of the crusting groove, the other end of the slurry returning pipeline is communicated to the other end of the slurry conveying pipeline through the slurry sucking pump, the slurry returning system is provided with a buffer pipeline, one end of the buffer pipeline is communicated to the slurry returning pipeline, and the other end of the buffer pipeline crosses the slurry sucking pump and is directly communicated to the slurry conveying pipeline. According to the present invention, with the yuba production apparatus, the liquid pressure in the slurry returning pipeline can be reduced according to the requirements, such that the damage of the slurry leakage on the slurry returning pump can be avoided, and the normal production performing can be ensured.

Owner:淮南徽旺豆制品设备有限公司

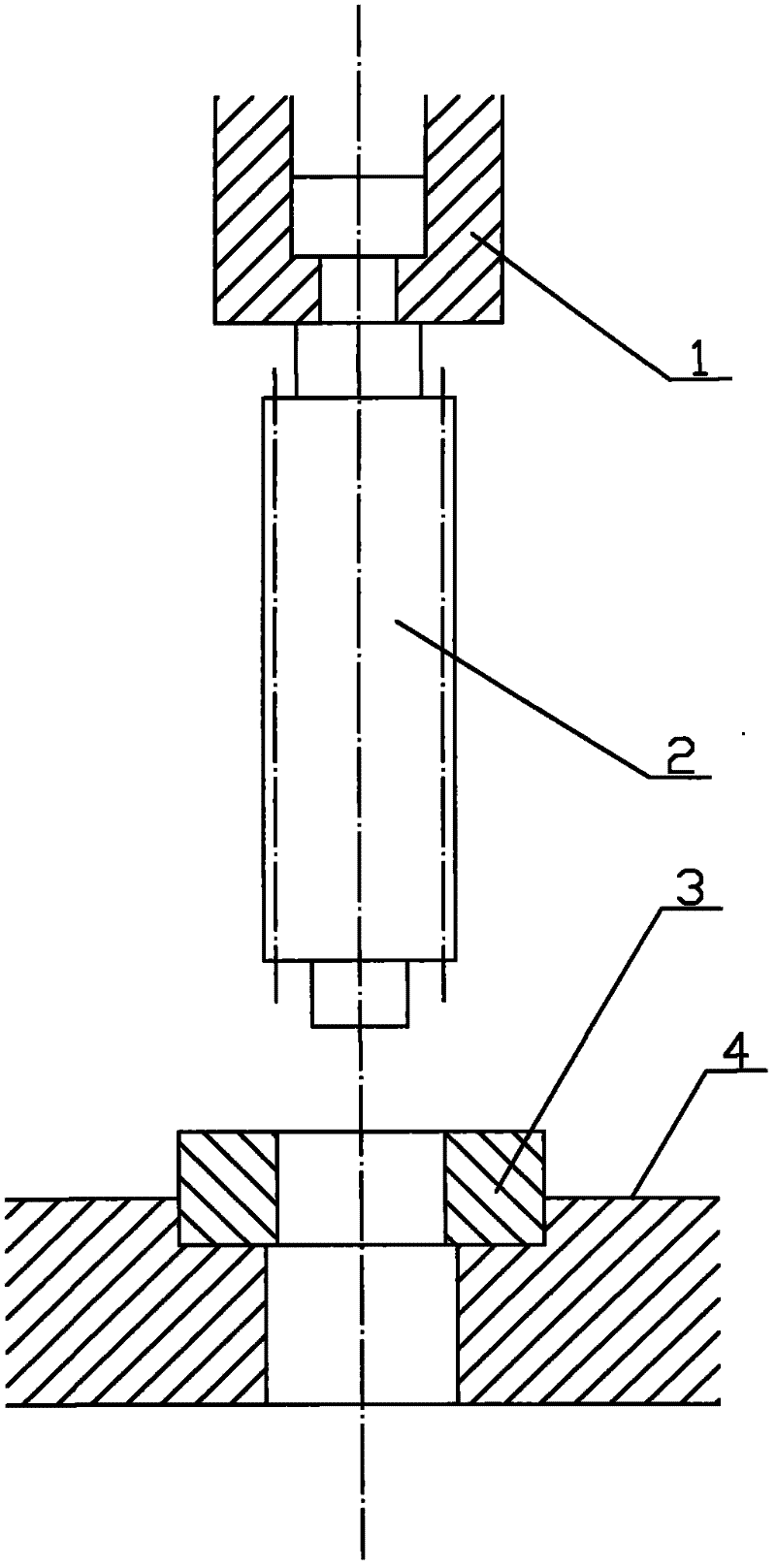

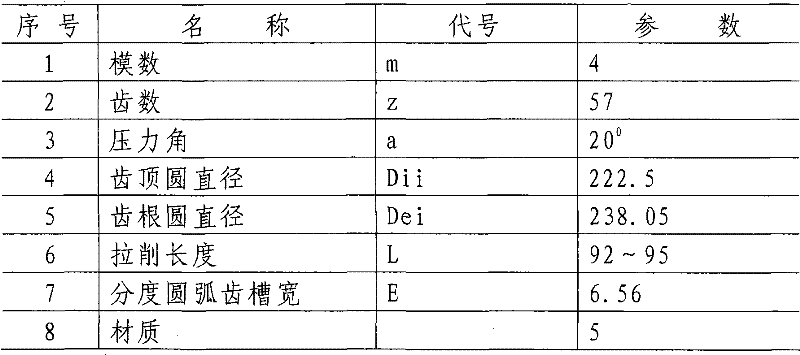

Push-broaching molding process of gear part of ring gear

ActiveCN102069237BImprove structural strengthHigh compressive strengthOther manufacturing equipments/toolsGear teethEngineeringMechanical engineering

The invention discloses a push-broaching molding process of a gear part of a ring gear. The process sequentially comprises the following steps that: (1) firstly a ring gear billet which is horizontally arranged is located and mounted on a worktable; (2) set push broaches are sequentially and vertically mounted on a pressure head respectively, wherein, the push broaches and the ring gear billet are coaxial, small ends of the push broaches are positioned on the bottom ends thereof, and big ends of the push broaches are positioned on the upper ends thereof; and (3) in the case of push broaching,the direction of thrust of the pressure head acting on the upper ends of the push broaches is consistent with the motion direction of the push broaches, the descending speed of the push broaches is 8-10mm / s, and the ascending speed of the push broaches is 14-18mm / s, wherein, (3.1) a push broach No.1 is adopted for locating and push-broaching the gear part under a cooling condition; (3.2) a push broach No.2 is adopted for push-broaching the gear part for rough molding under a cooling condition; and (3.3) the push broaches No. 3, 4, 5 are sequentially adopted for push-broaching the gear part for precision molding under a cooling condition. The adopted push broaches have short axial size and good rigidity, thus the push-broaching molding process has the advantages of fast push-broaching speed, stable quality and high production efficiency; and short stroke is required for the pressure head of a press machine in the push-broaching molding process, thus the press machine is easily purchased.

Owner:TAIZHOU LIHUA MACNINERY

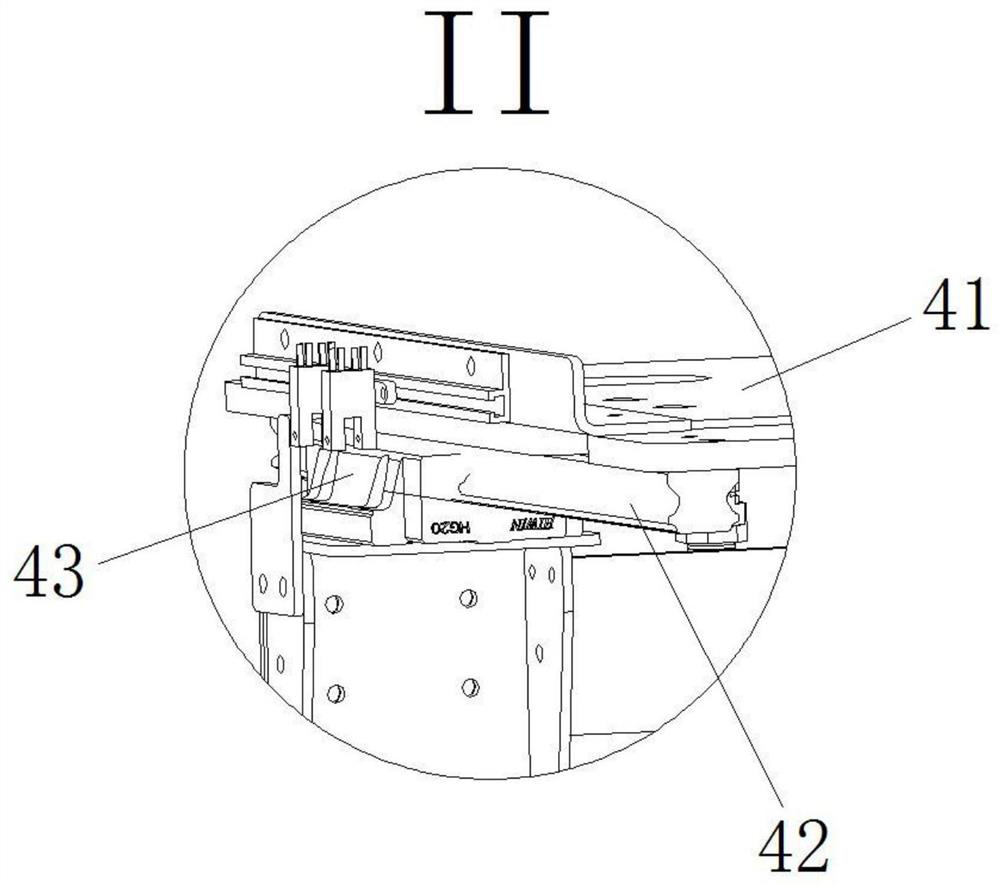

Four-axis tire mold cutting plotter and its marking method

The invention provides a four-shaft character carving machine for tire molds and a character carving method thereof. The four-shaft character carving machine comprises a base, a rotary work table located at one end of the base, a vertical column base fixed to the base in a sliding mode, a vertical column fixed to the vertical column base, a main shaft saddle fixed to one side surface of the vertical column in a sliding mode, a rotary index plate fixed to the main shaft saddle in a sliding mode, a main shaft combination base fixed to the end of the rotary index plate and an electric main shaft located in the main shaft combination base; a first transmission device is arranged on the side surface of the vertical column, a second transmission device is arranged on the main shaft saddle, the main shaft saddle is fixed to the first transmission device in a sliding mode, and the rotary index plate is fixed to the second transmission device in a sliding mode. According to the machine and the method, the transmission devices in multiple directions control the four-shaft character carving machine for the tire molds, the machining depth direction of the electric main shaft is always perpendicular to the curved surfaces of the tire molds, the cost of mold damage caused by human factors is lowered, the overall work efficiency is improved, and the qualification rate of products is increased.

Owner:群基精密工业(苏州)有限公司

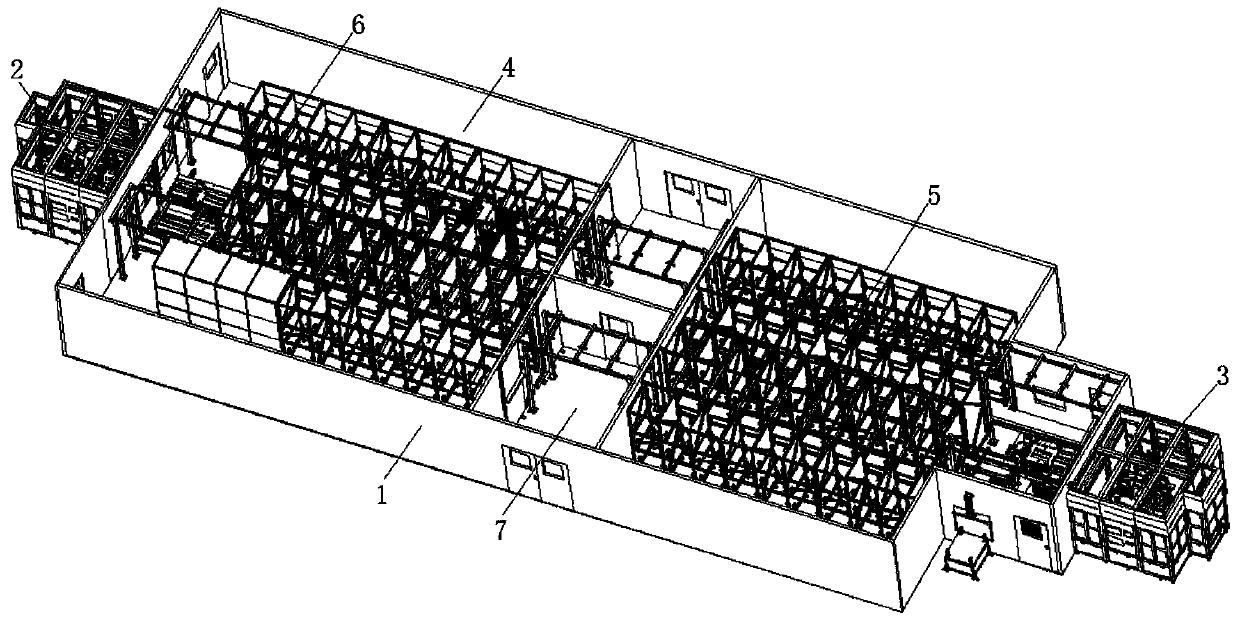

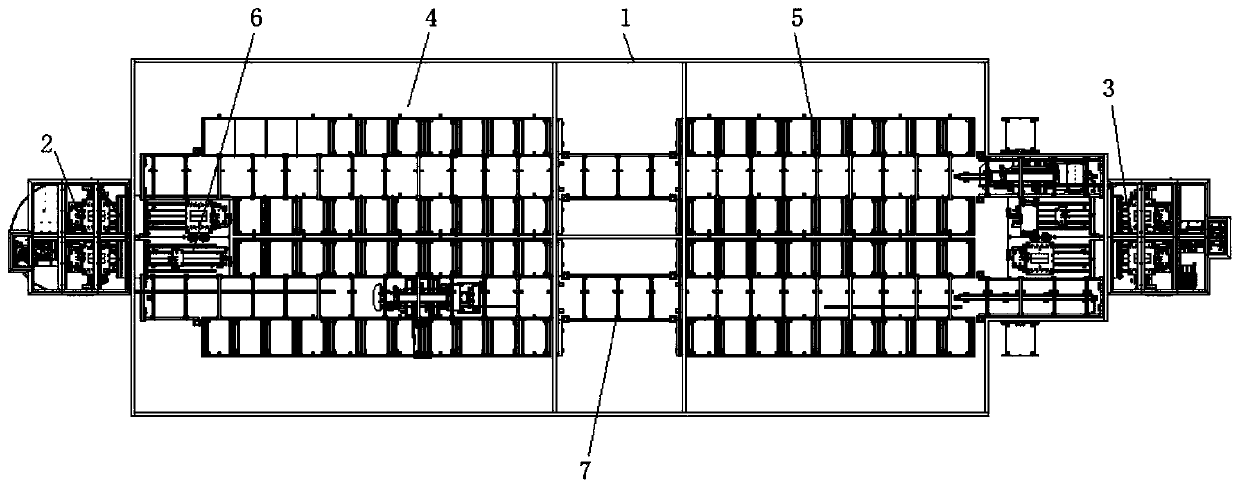

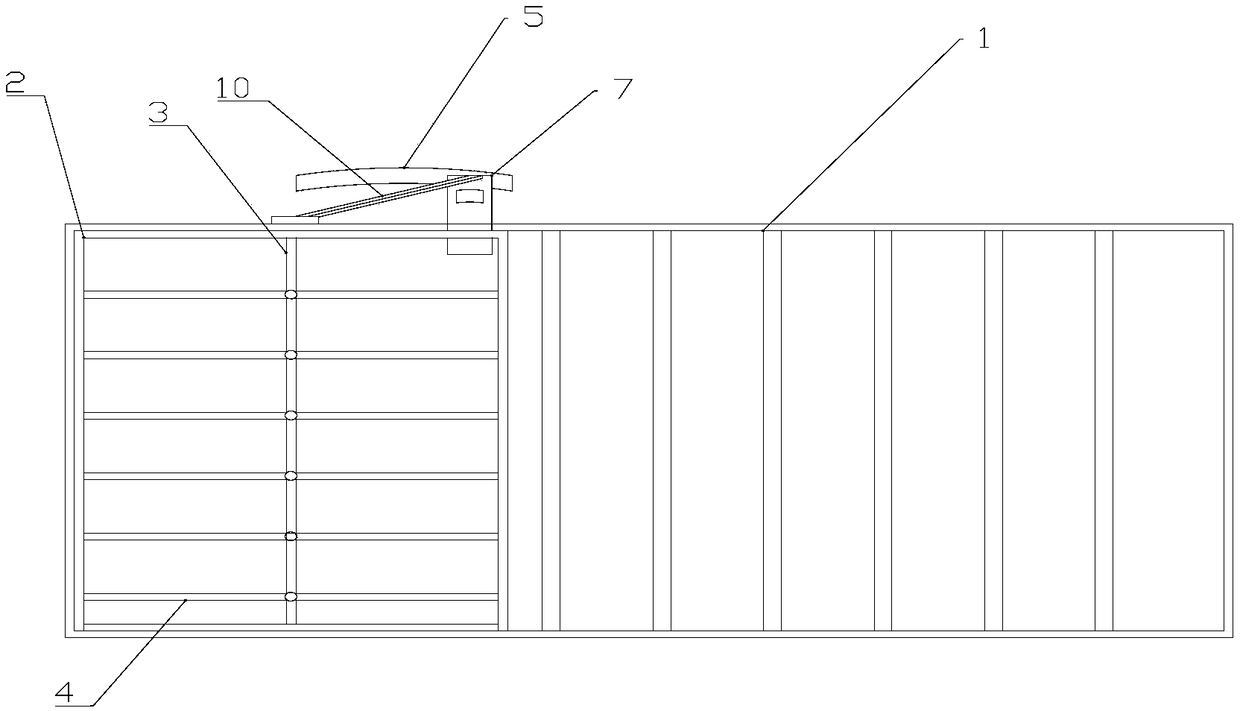

High-temperature static room

The invention relates to the technical field of lithium battery production, and discloses a high-temperature static room. The high-temperature static room comprises a static room main body part, a feeding part, storage parts, a goods shelf, an RGV transportation part and an RGV maintenance part, wherein the feeding part is positioned in the middle of the left side of the body part of the static room, the discharging part is located in the middle of the right side of the static room main body part, the two storage parts are located on the two sides of the static room main body part respectively, the goods shelf is located in the storage part, and the RGV transport part is located in the middle of the interior of the body part of the static room. According to the high-temperature static room, the purpose of automatically conveying a lithium battery is achieved, and meanwhile, the temperature of the room can be uniformly controlled and recycled through the main body part of the high-temperature static room, the energy is saved, the environment is protected, the space is saved, the operation is simple, the full-automatic feeding and discharging are realized, the efficiency is high, and the productivity is improved.

Owner:SHENZHEN TENGDA IND AUTOMATIC EQUIP

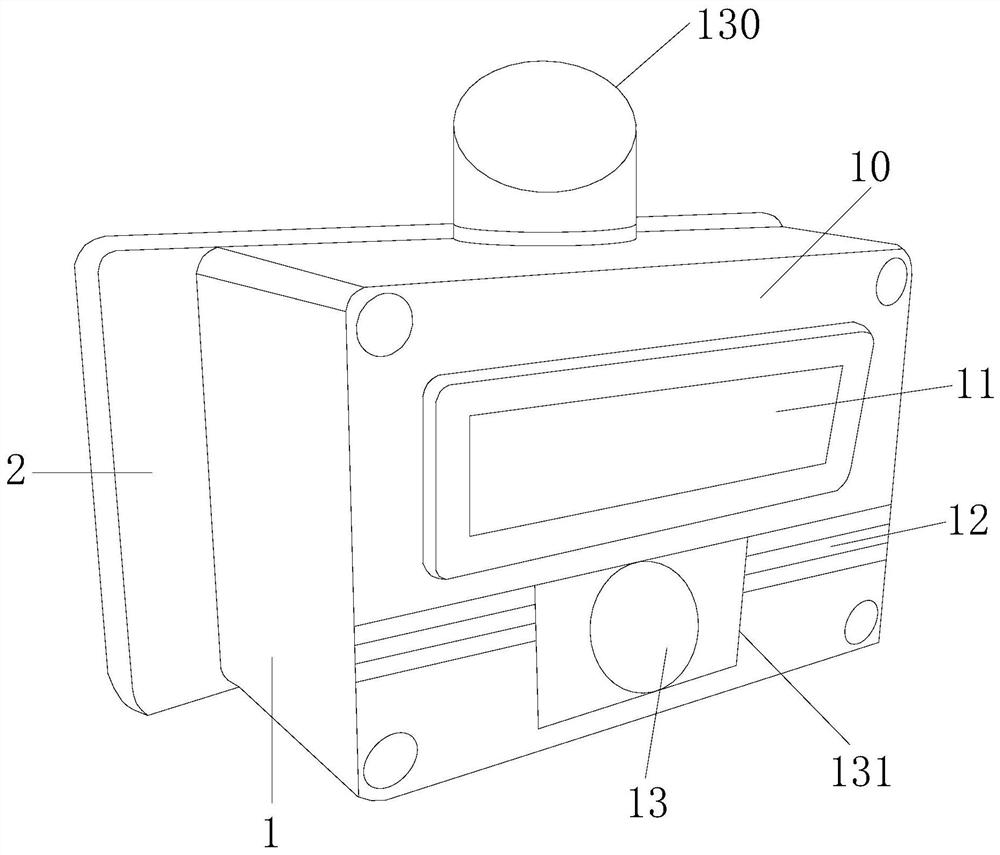

Key device of instrument

InactiveCN105118719APrevent hooking and pulling outThe preventer is set offElectric switchesKey pressingDamage cost

The invention provides a key device of an instrument. The key device comprises a groove, a key and a lantern ring, wherein the groove is formed in the outer frame of the instrument; a through hole is formed in the groove; the key is arranged in the through hole of the groove in a penetrating manner; a clamping flange is arranged at the bottom of the key in a convex manner, and is clamped on the bottom surface of the through hole in the groove; the height of the outer edge of the key is smaller than the depth of the groove; the lantern ring sleeves the bottom of the key. The design provided by the invention prevents the key of a motorcycle instrument from being hooked, pulled out or raised, instrument damage caused by rain water penetration is avoided, and damage cost is reduced.

Owner:CHONGQING DACHENG GRACE NC TECH CO LTD

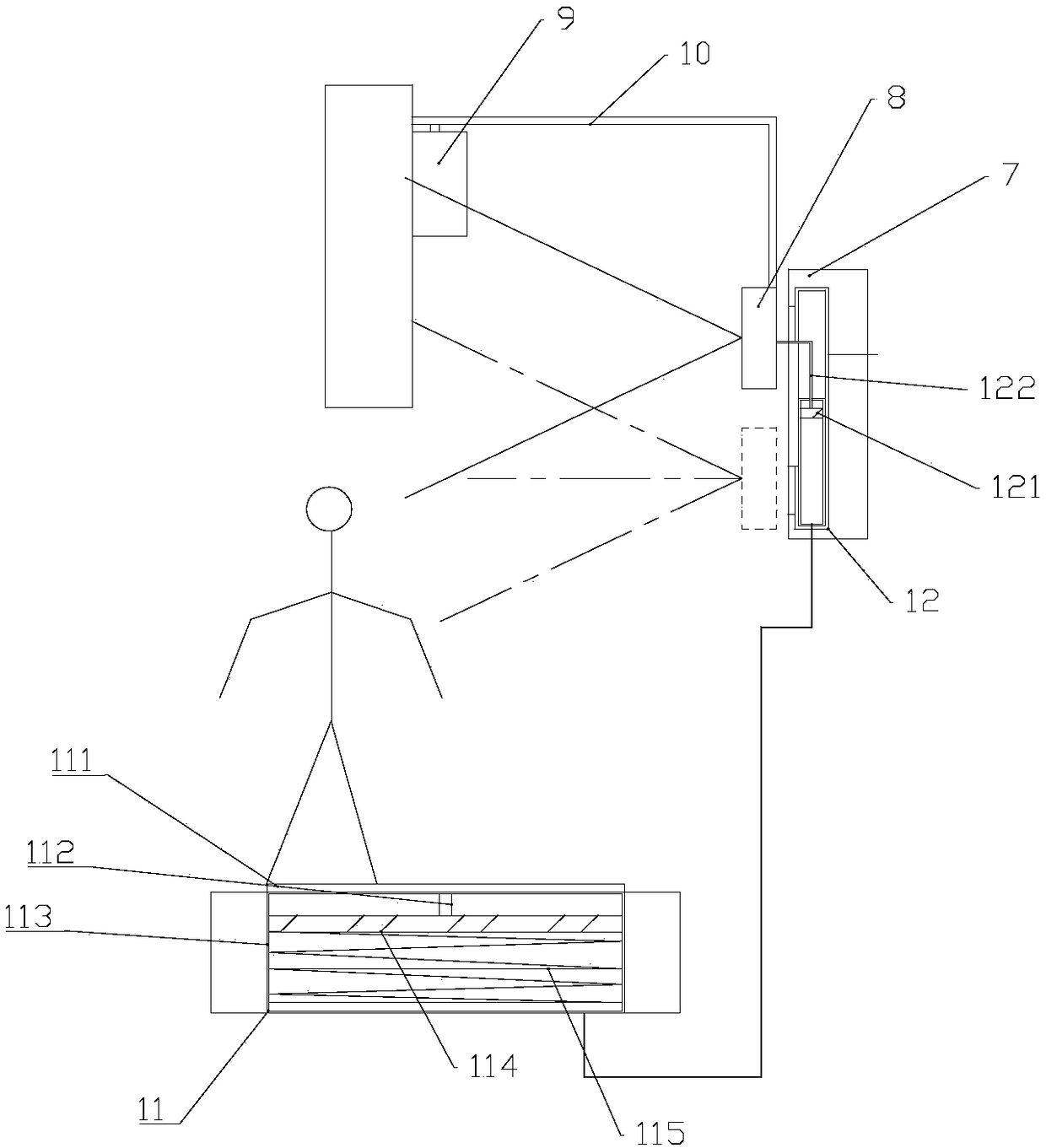

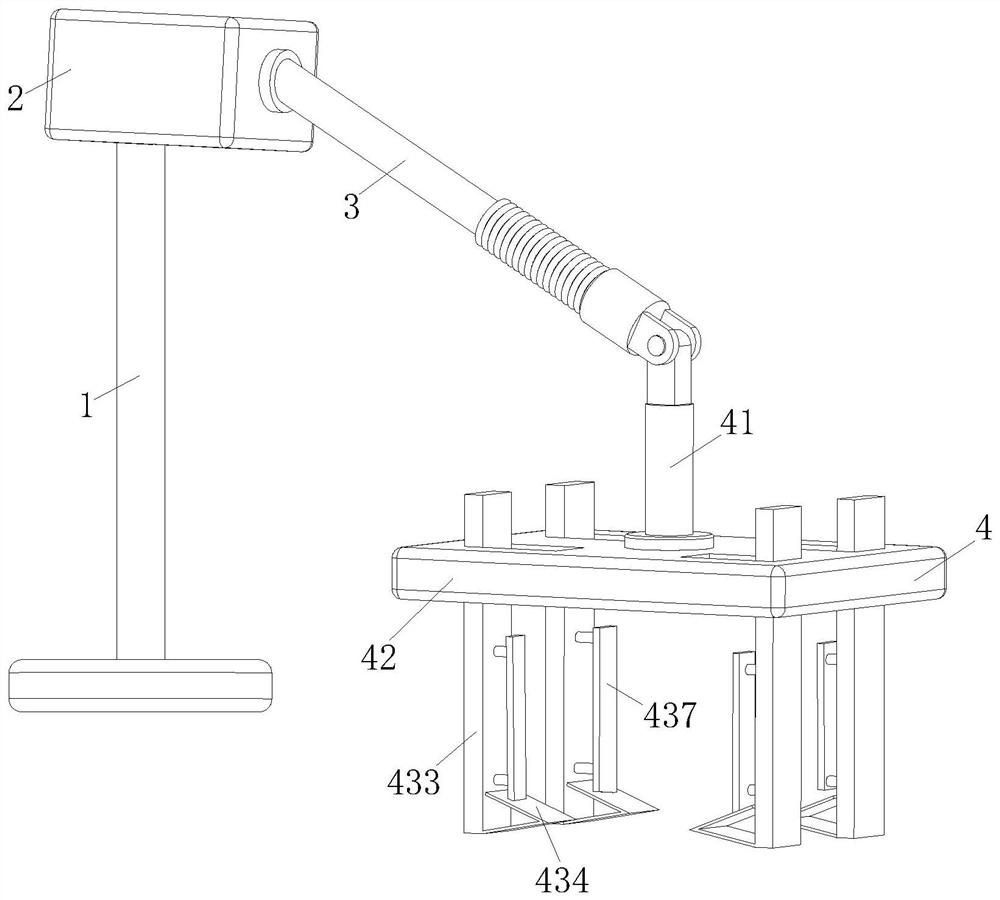

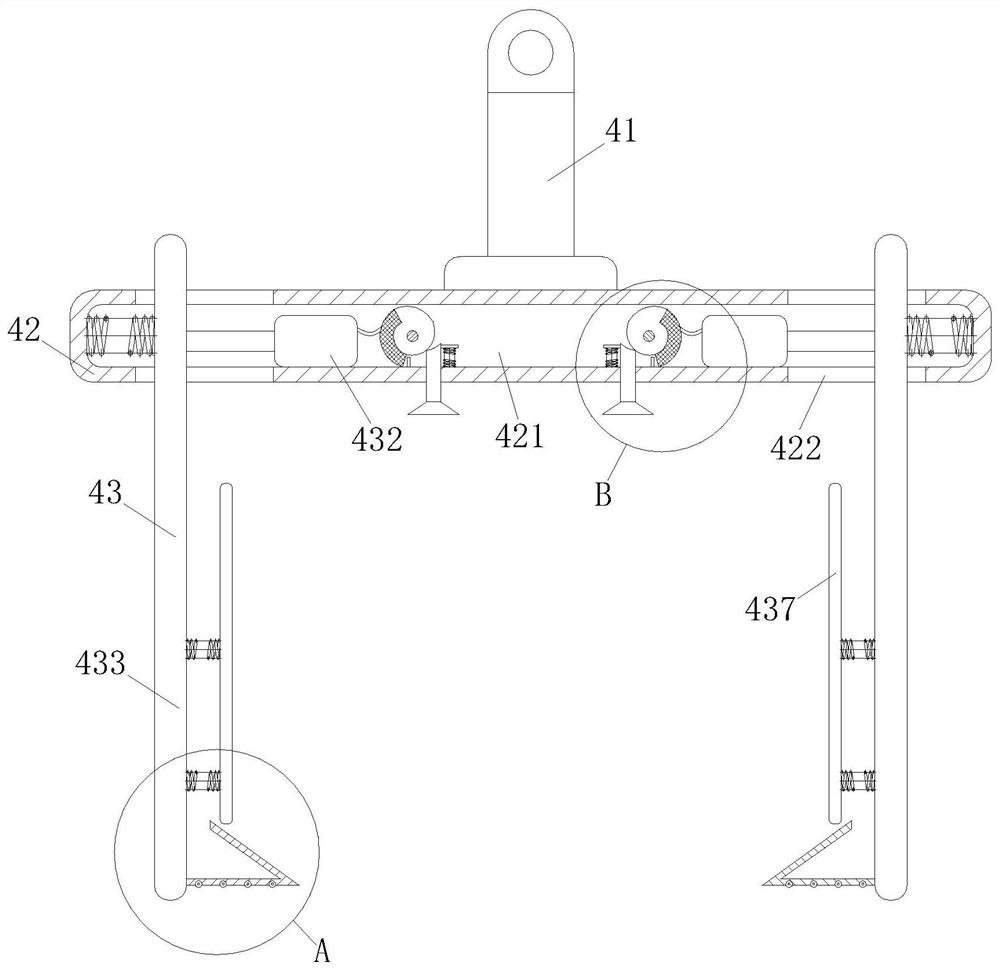

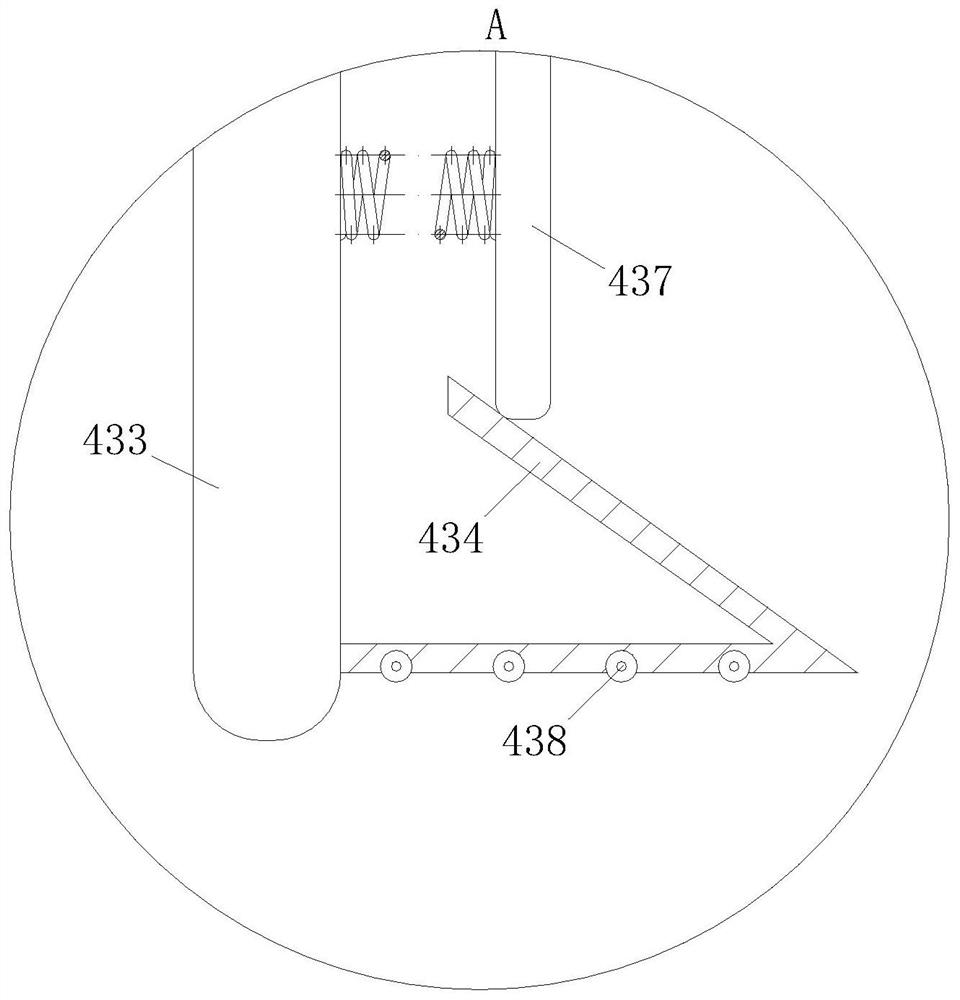

Data acquisition device for building entrance guard management

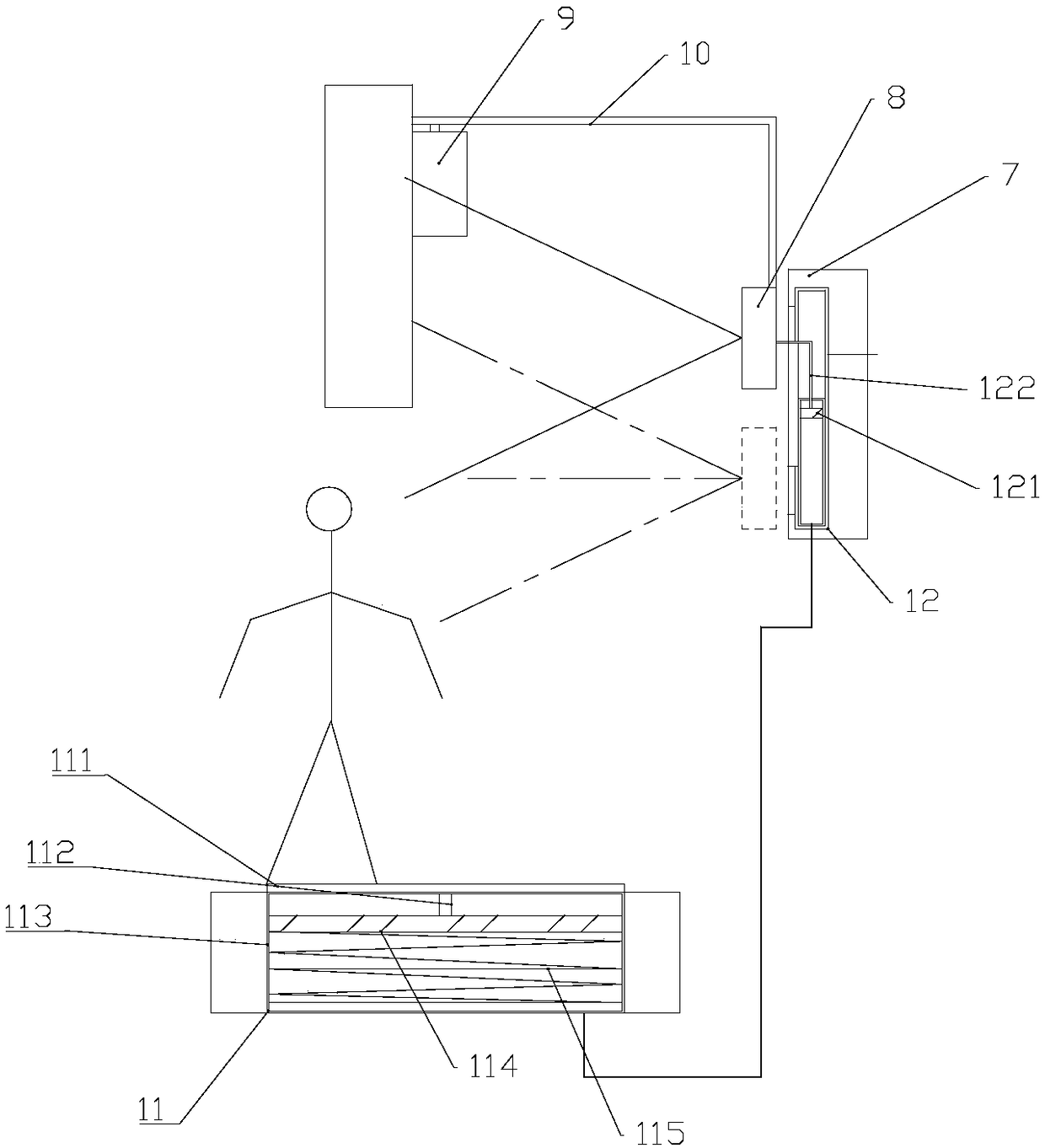

PendingCN108765667AHigh precisionEasy to collectCharacter and pattern recognitionIndividual entry/exit registersData acquisitionInformation acquisition

The invention relates to an information acquisition part of an entrance guard system, in particular to a data acquisition device for building entrance guard management. The data acquisition device forbuilding entrance guard management comprises a door main body and a rotary doorsill installed on the door main body and also comprises an image acquisition part, an acquisition driving mechanism andan arc-shaped sliding rail, wherein the arc-shaped sliding rail is installed on the inner side of the rotary doorsill, and the acquisition driving mechanism comprises a plurality of push rods peripherally fixed to a rotary shaft, an installing frame for installing the image acquisition part, a buffer spring installed in the arc-shaped sliding rail and arranged on one side of the installing frame and a reset spring installed in the arc-shaped sliding rail and arranged on the other side of the installing frame. When an entrance guard user pushes the rotary doorsill, the push rods push the installing frame to slide, the shape of the arc-shaped sliding rail makes the installing frame gradually away from the push rods and break away from the push rods in the pushed process, and the image acquisition part shoots radial images of the rotary shaft in the sliding process. The data acquisition device can acquire face data of more persons passing an entrance guard.

Owner:CHONGQING HUIJU INTELLIGENT ELECTRONICS

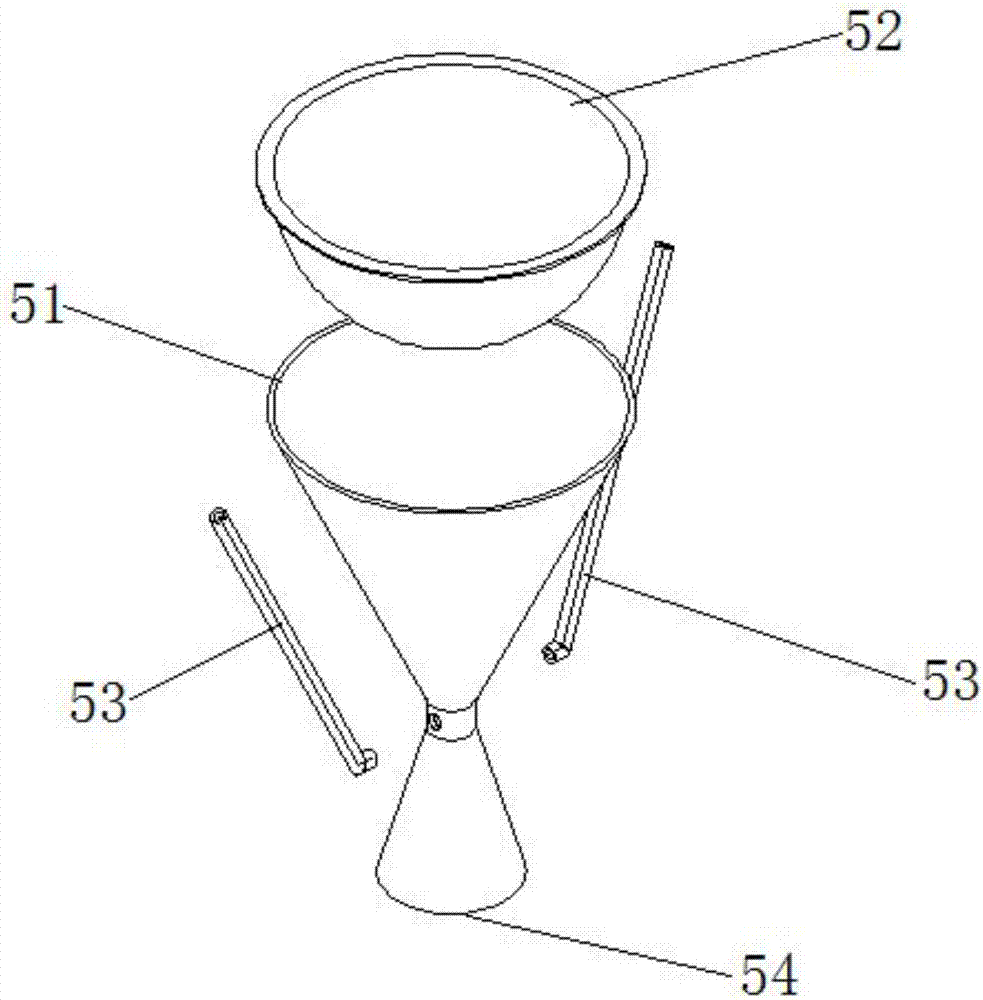

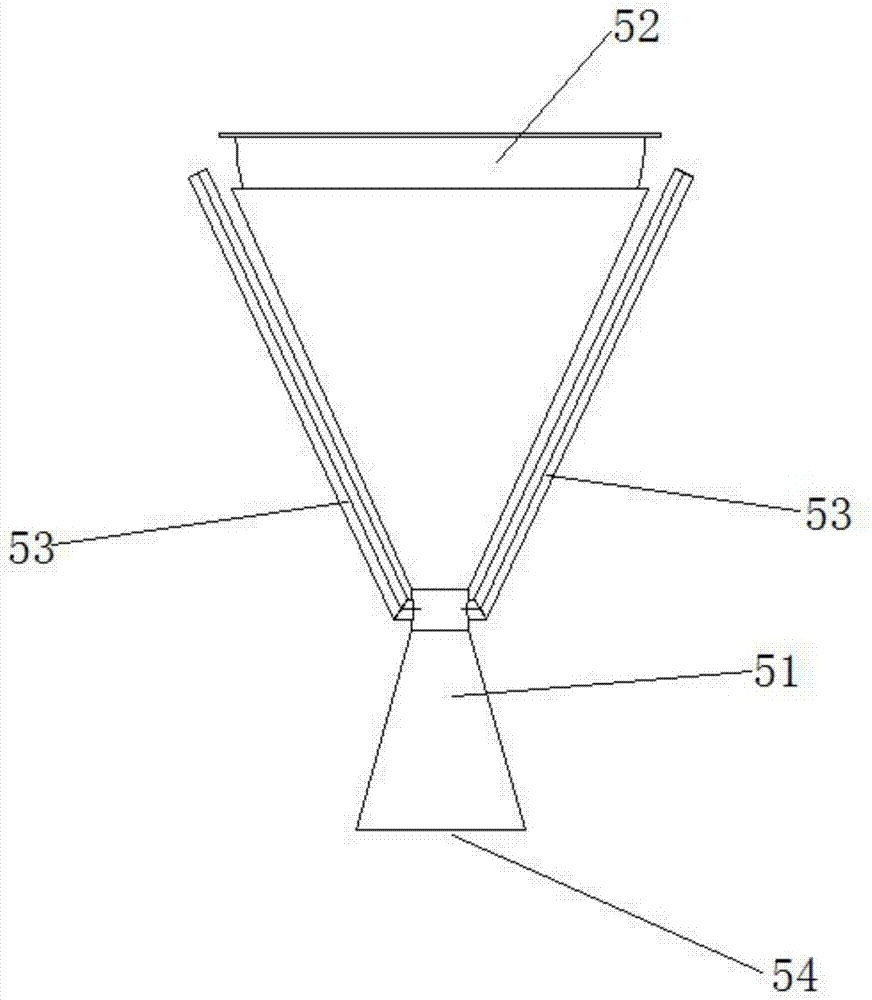

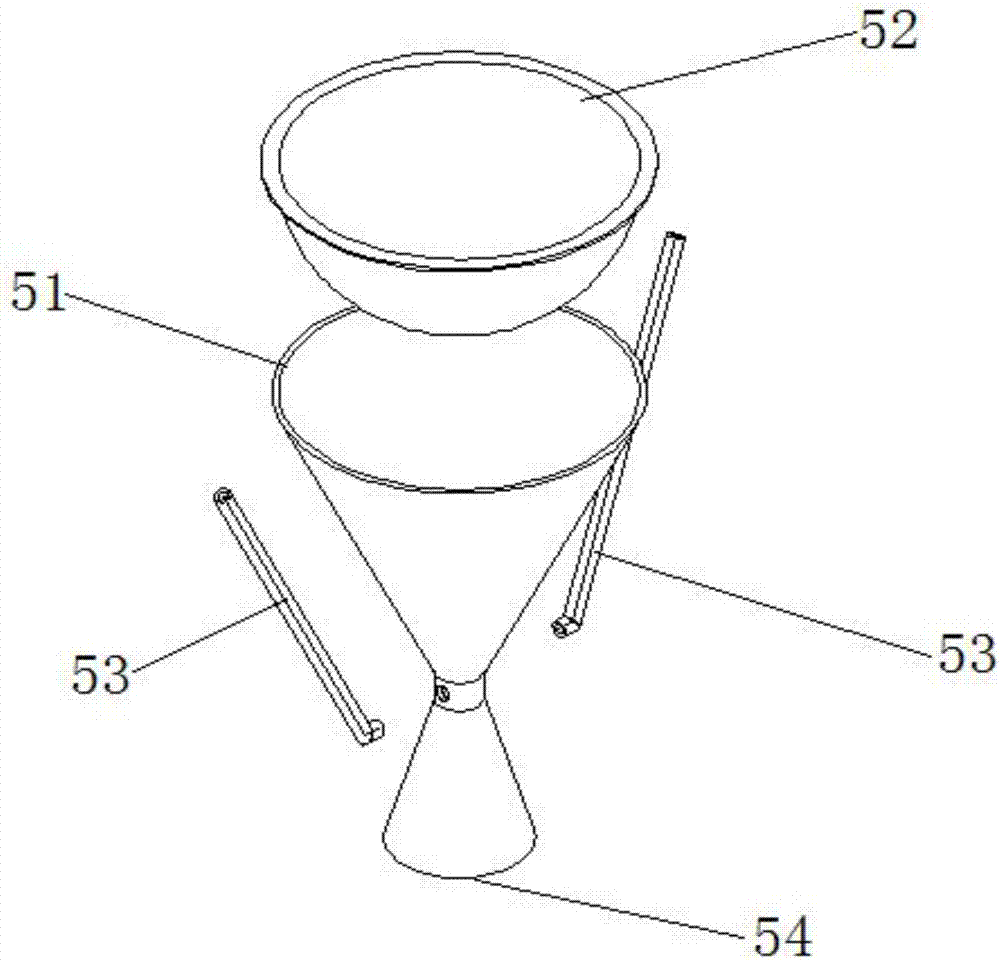

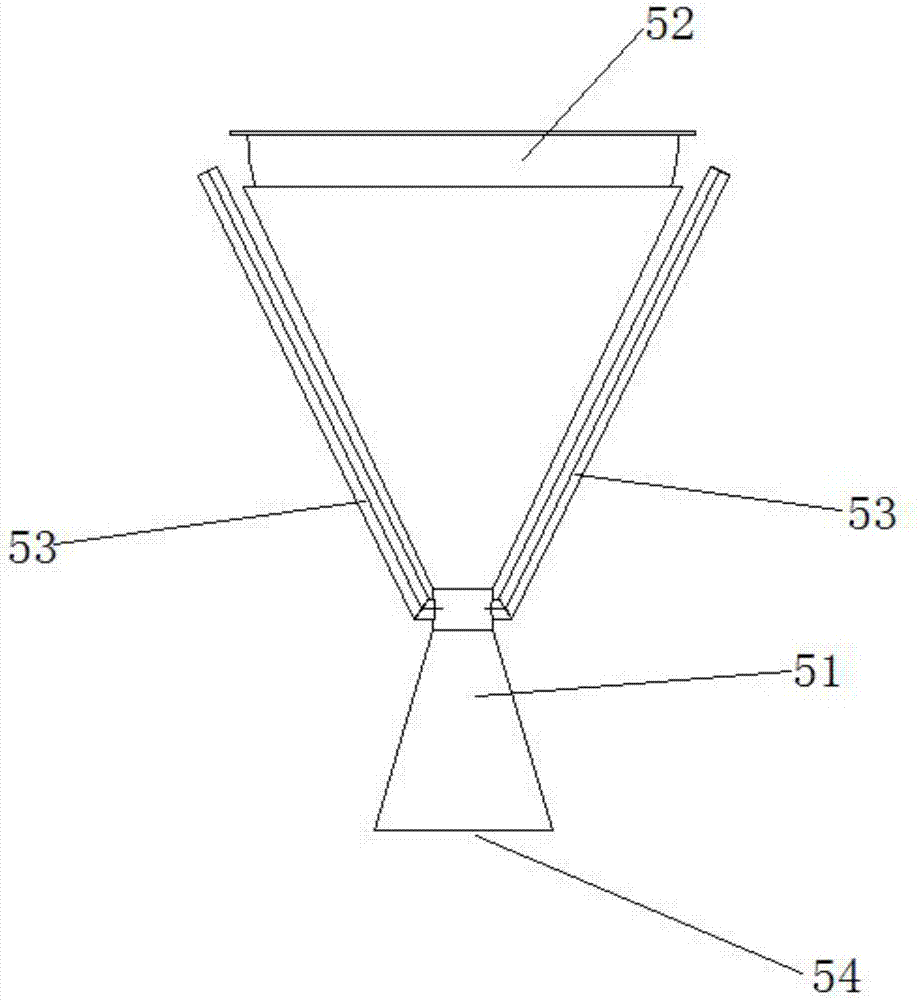

Soybean milk mixer

PendingCN107980914ASimple structureNo energy consumptionMilk substitutesFood scienceSoybean productEngineering

The invention discloses a soybean milk mixer and belongs to the field of soybean product processing. The soybean milk mixer comprises a net-shaped diffuser, a mixer main body, a milk outlet and gas channels, wherein the net-shaped diffuser is positioned at the top end of the mixer main body; the milk outlet is formed in the tail end of the mixer main body; the mixer main body is of a Venturi tubestructure; and the gas channels are positioned in two sides of the mixer main body and are communicated with the mixer main body. The invention discloses the soybean milk mixer which is applicable tomechanical or manual production process of soybean products, is capable of efficiently mixing former and new soybean milk, and is simple in structure, free of energy consumption and convenient to clean.

Owner:淮南徽旺豆制品设备有限公司

Automatic pipe loading and feeding mechanism

InactiveCN114162520AAvoid getting stuckSmooth feedingConveyorsLoading/unloadingControl engineeringStructural engineering

The invention relates to an automatic pipe loading and feeding mechanism which comprises a table body, a guardrail is installed at the top of the table body, a limiting assembly is arranged on one side wall of the table body, a connecting plate is installed on one side wall of the table body, a fixing frame is installed on one side wall of the connecting plate, and a plum blossom wheel is installed on one side wall of the fixing frame through a bearing. A sliding block is slidably connected to one side wall of the fixing frame, a connecting rod is installed on one side wall of the sliding block through a bearing, a shifting block is installed at one end of the connecting rod and connected with the plum blossom wheel in a clamped mode, a first servo motor is installed on one side wall of the table body, and the output end of the first servo motor is connected with a connecting rod; through the arrangement of the connecting plate, the plum blossom wheel, the fixing frame, the sliding block, the connecting rod, the first servo motor, the connecting rod and the shifting block, pipes can be continuously conveyed one by one, so that the situation that a plurality of pipes are clamped in the feeding process is effectively prevented, feeding is smoother, the working efficiency is improved, and the feeding speed is increased.

Owner:佛山市明州智能设备有限公司

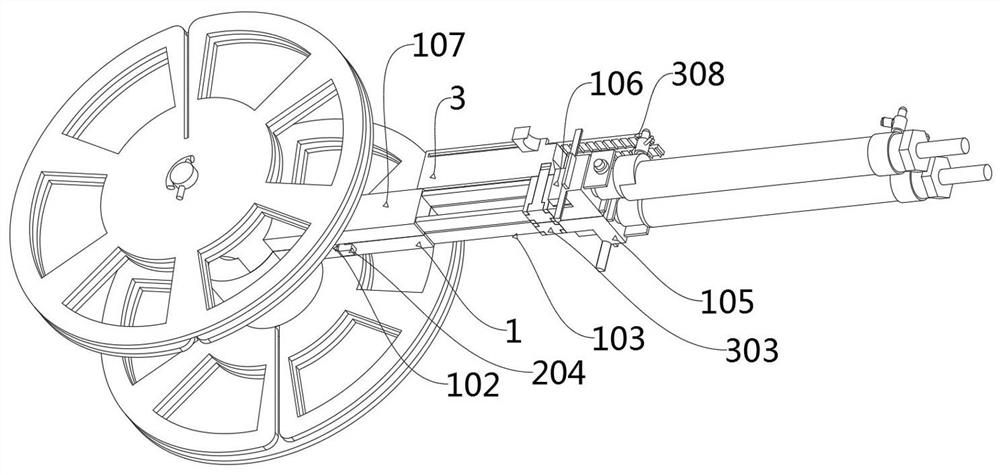

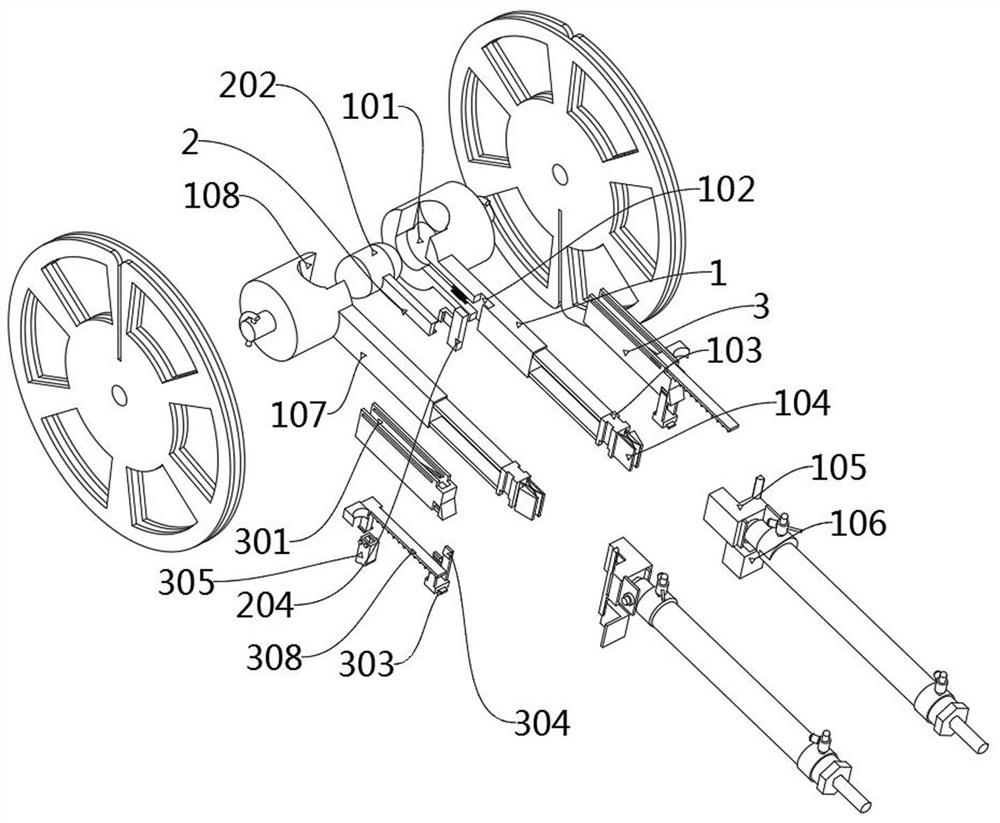

Baolun adjustment mechanism of high-speed embroidery equipment for textile manufacturing and processing

ActiveCN113373608BAvoid damageLow costAutomatic machinesAuxillary devicesTextile manufacturingMechanical engineering

Owner:南通福端达纺织有限公司

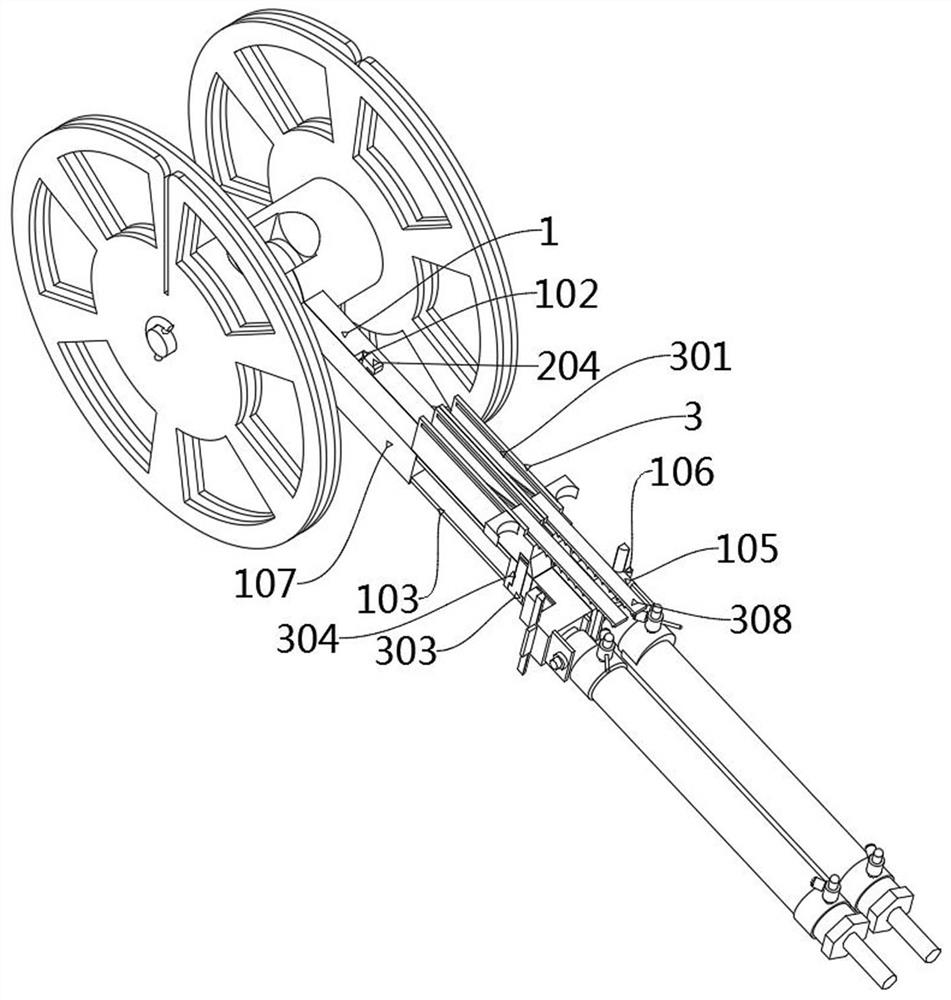

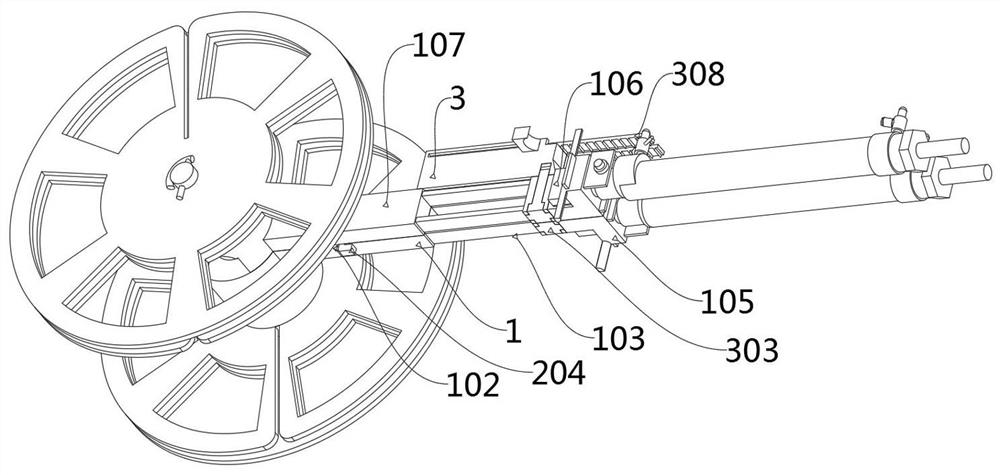

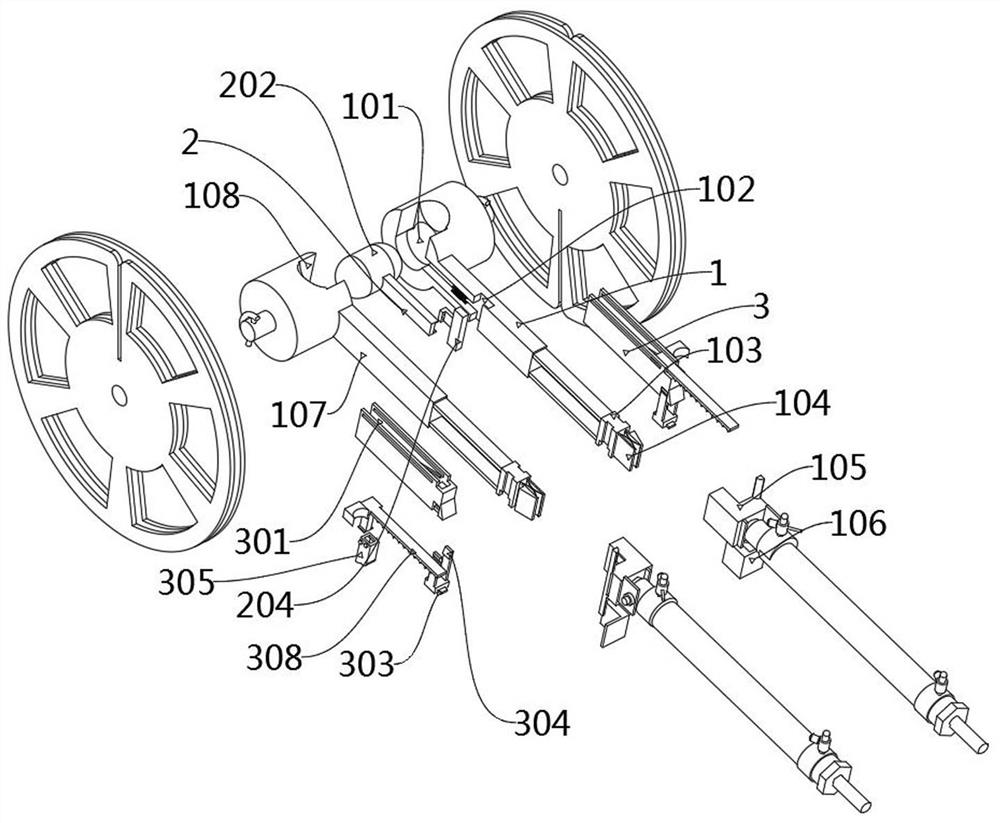

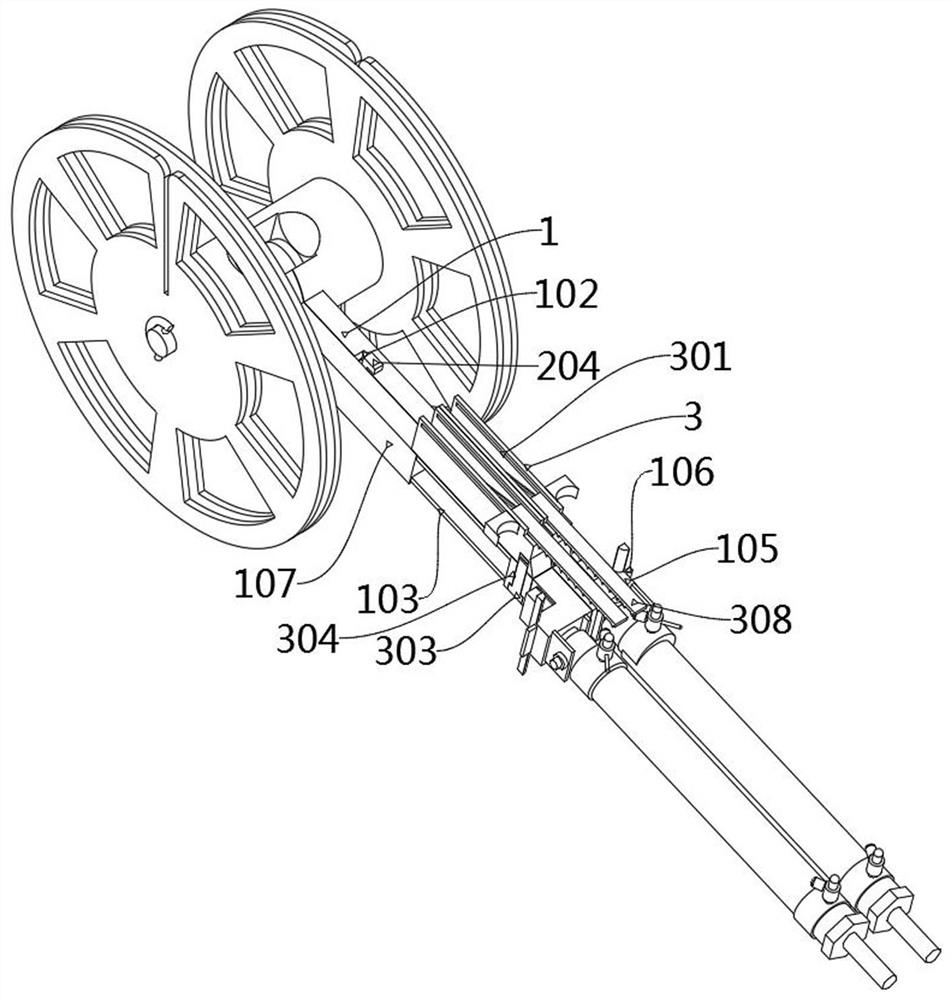

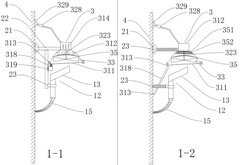

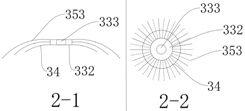

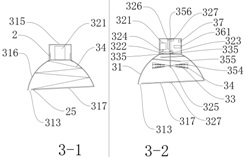

Wheel adjusting mechanism of high-speed embroidery equipment for textile manufacturing and processing

ActiveCN113373608AAvoid damageLow costAutomatic machinesAuxillary devicesTextile manufacturingMechanical engineering

The invention provides a wheel adjusting mechanism of high-speed embroidery equipment for textile manufacturing and processing, relates to the field of textile machinery, and aims to solve the problems that an existing wheel adjusting mechanism of the embroidery equipment is not convenient to adjust, the moving distance of wheels cannot be controlled, and the adjusting structure cannot be conveniently disassembled after a vacancy exists between the wheels. The wheel adjusting mechanism of high-speed embroidery equipment for textile manufacturing and processing comprises a main body and a mounting part, wherein the main body is of an L-shaped structure; the left end of the main body is of a cylindrical structure; the wheels are mounted on the outer side of the left end of the main body through a plug pin and a shaft rod; the mounting part is mounted on the inner side of the main body; an adjusting part is mounted above the right end of the main body; and a limiting mechanism is mounted at the right end of the mounting part. An adjusting plate is controlled to move leftwards, a wedge-shaped block can be in contact with the top end of an inner groove, the bottom of a pushing block can push a spring plate of a control rod to be bent, the moving distance of the wheels is adjusted, and then the wheels can be effectively used for sheet feeding, so that the service life of the wheels is longer, and the maintenance and replacement cost is reduced by 5000 yuan per month.

Owner:南通福端达纺织有限公司

Chip taut manual pick-up device

ActiveCN110335846BIncrease distanceImprove the efficiency of manual pickingSemiconductor/solid-state device manufacturingStructural engineeringMechanical engineering

Owner:QINGDAO AEROSPACE SEMICON RES INST

Novel dried bean curd stick production device

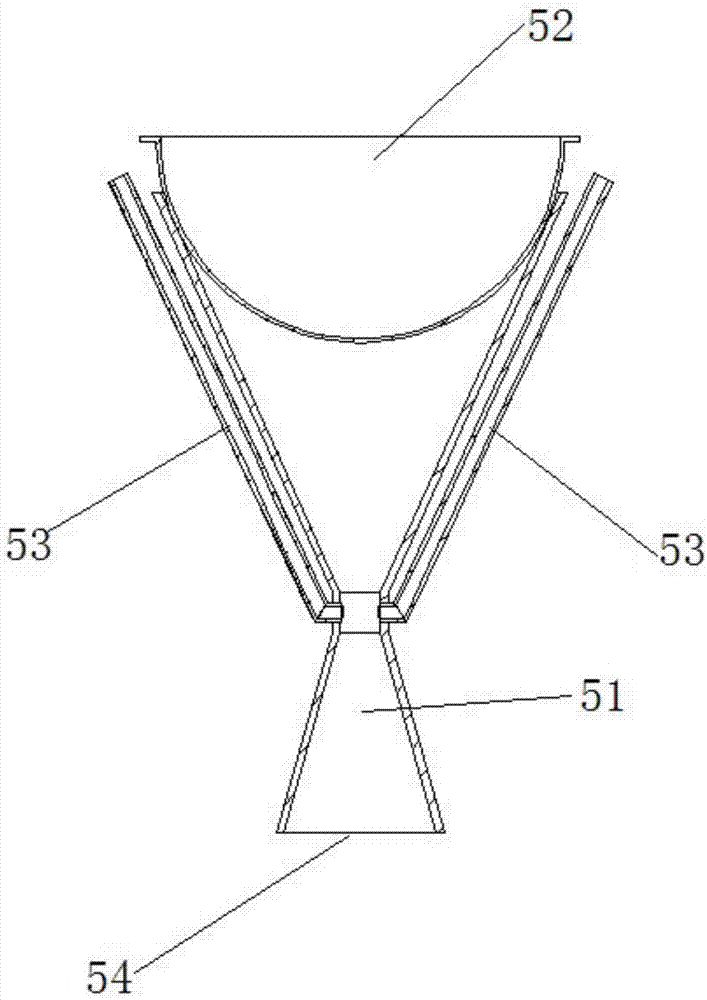

PendingCN107960484AEfficient mixingSimple structureCheese manufactureFood sciencePulp and paper industryDry bean

The invention discloses a novel dried bean curd stick production device, and belongs to the field of dried bean curd stick processing. The device comprises a peeling pot, a new pulp inlet pipe, a pulpreturning pipe, a pulp discharging pipe, a pulp extraction pump and a soybean milk mixer, the soybean milk mixer comprises a hemispherical disperser, a mixer body, a pulp outlet and gas air channels,the disperser is positioned at the top end of the mixer body, a screen is arranged at the bottom of the disperser, the pulp outlet is positioned in the tail end of the mixer body, an upper screen isarranged on the top surface with a maximum radius, a centre point of the upper screen is provided with a bearing, the bearing is connected with a rotating shaft, rotating blades are arranged on the rotating shaft, the mixer body is of a Venturi tube structure, the gas air channels are formed in two sides of the mixer body and communicated with the mixer body, the netted disperser is abutted to thenew pulp inlet pipe and the pulp returning pipe, and the pulp outlet is abutted to the peeling pot. According to the dried bean curd stick production device with the soybean milk mixer, new soybean milk and old soybean milk can be efficiently mixed, and the soybean milk mixer is simple in structure, free from energy consumption and convenient to clean.

Owner:淮南徽旺豆制品设备有限公司

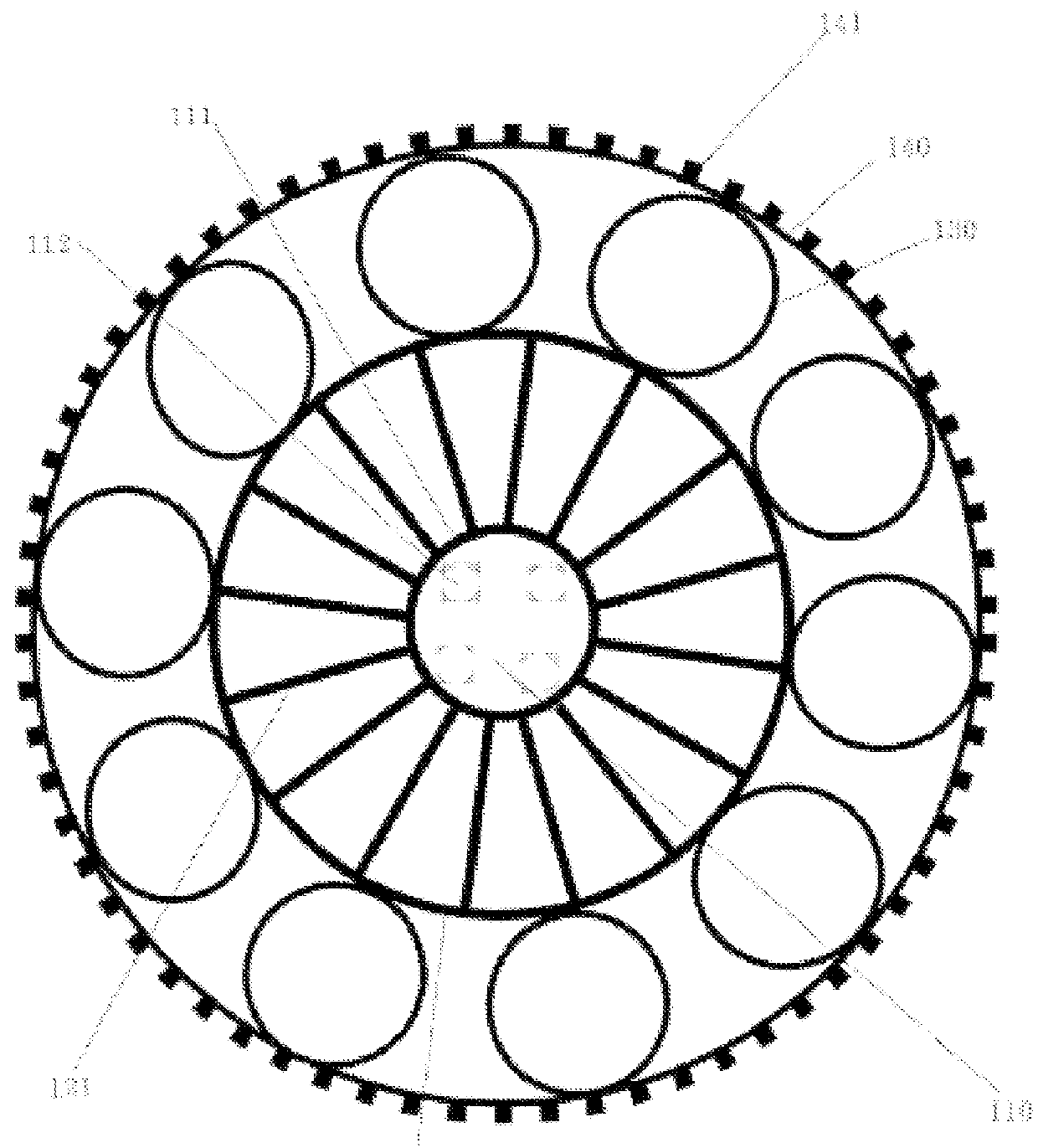

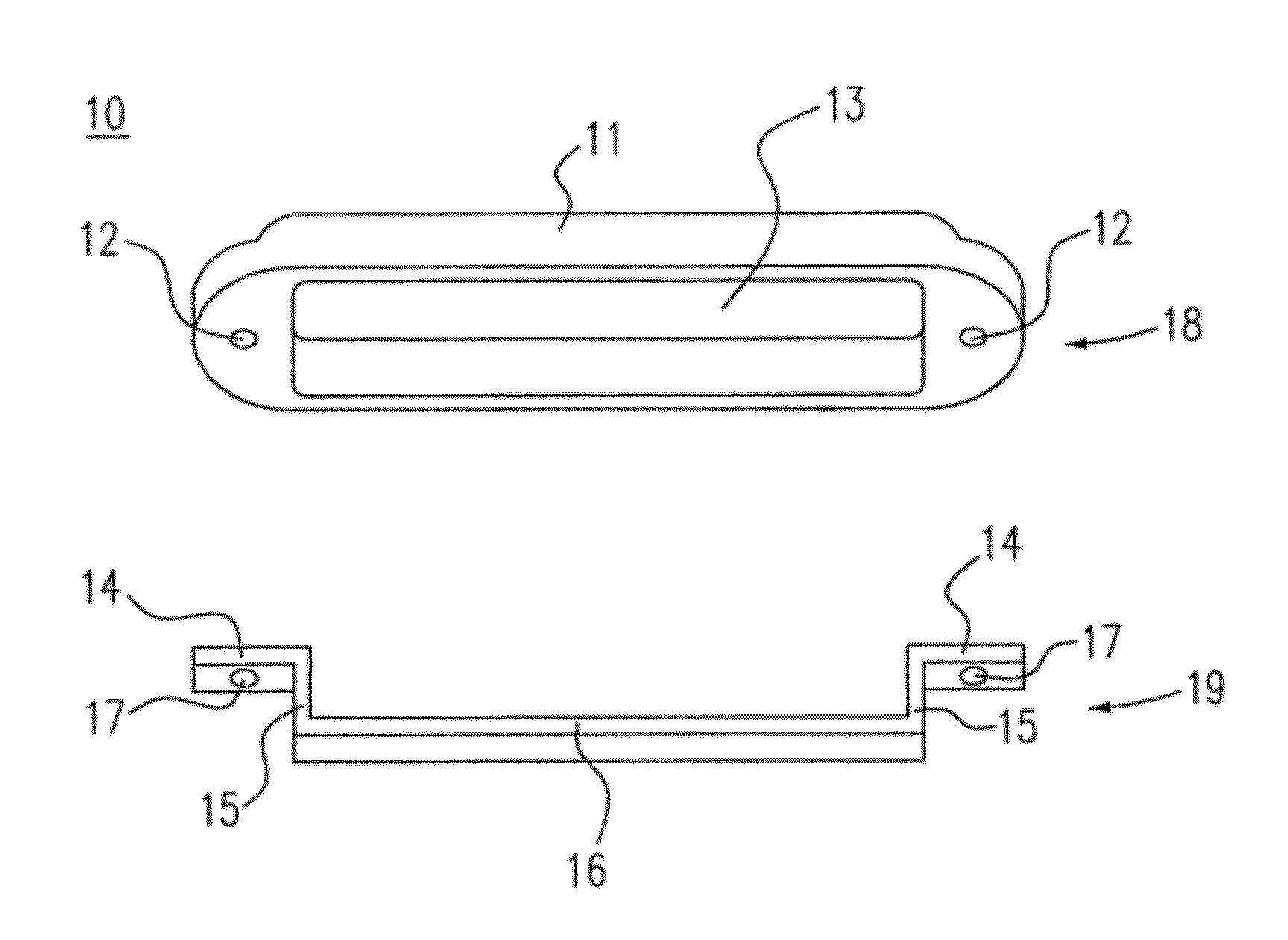

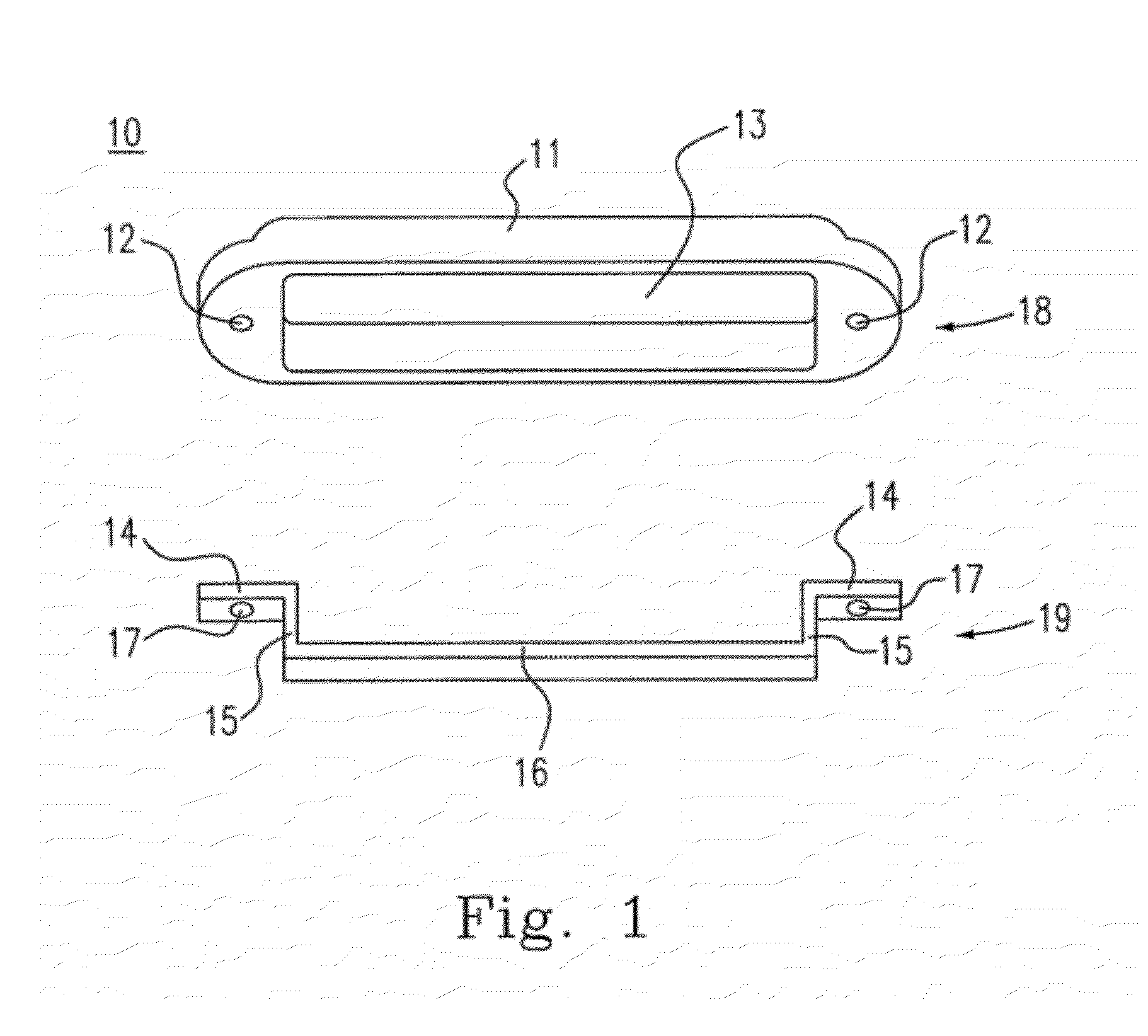

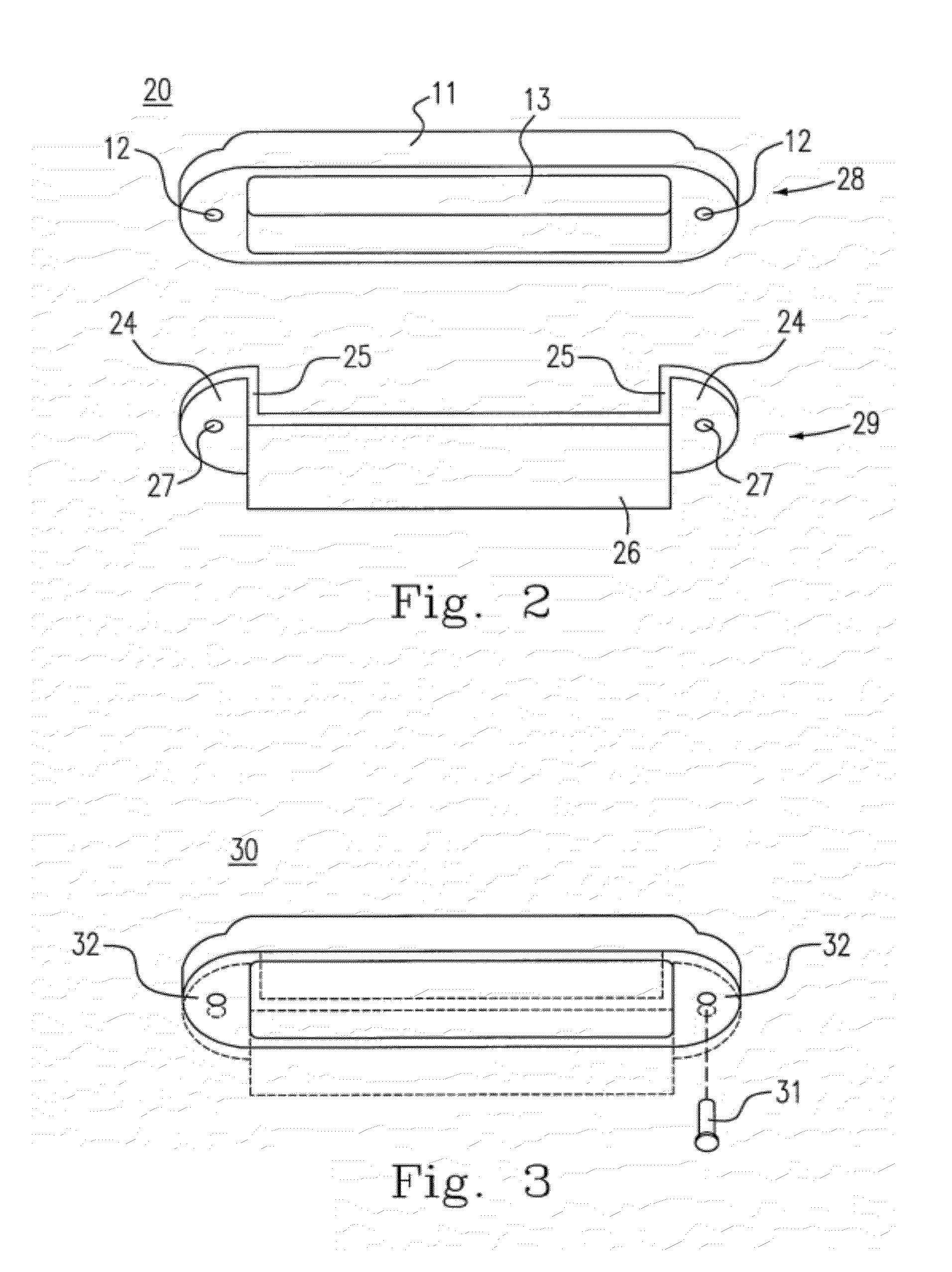

Nonslip circular flange

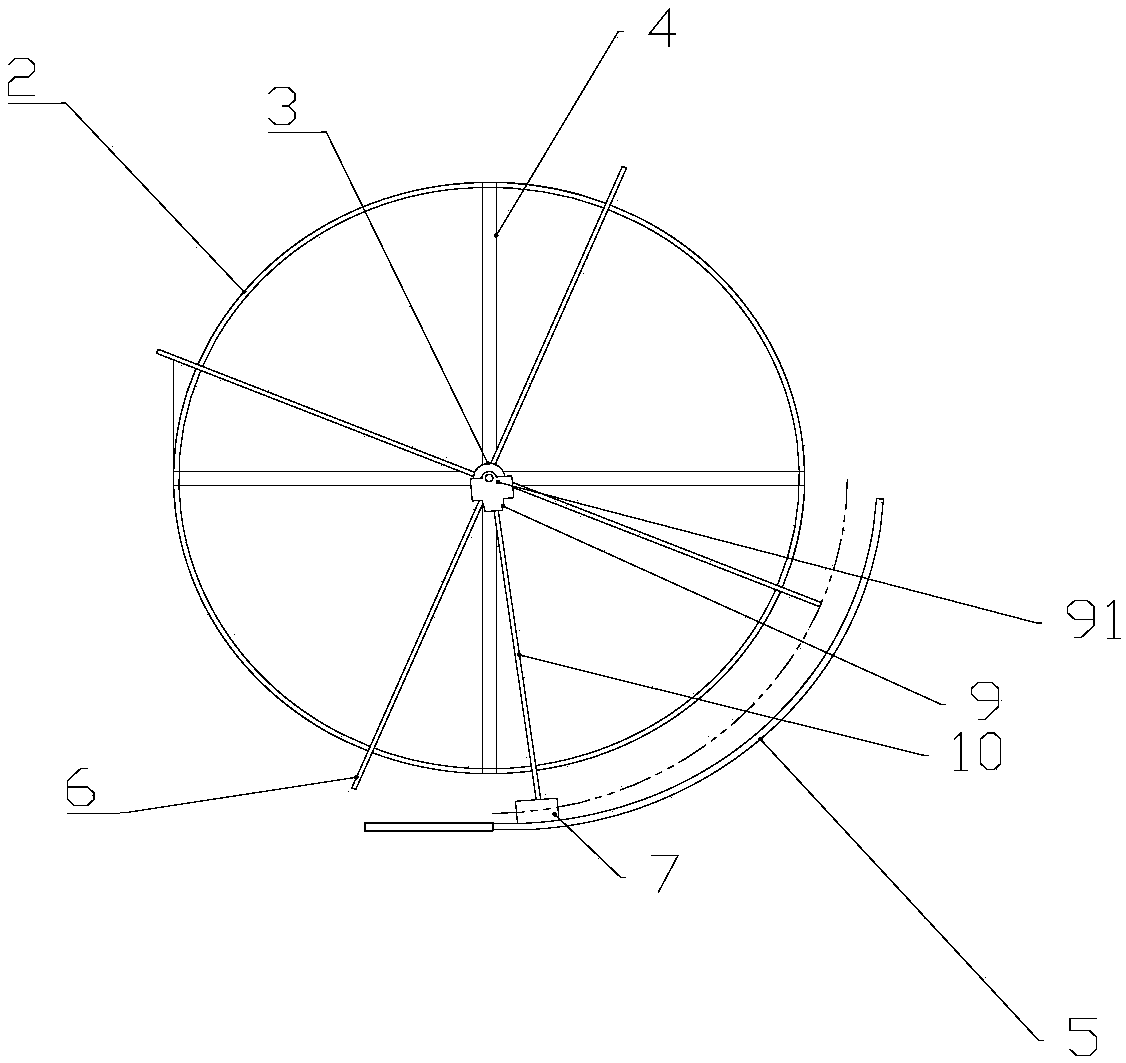

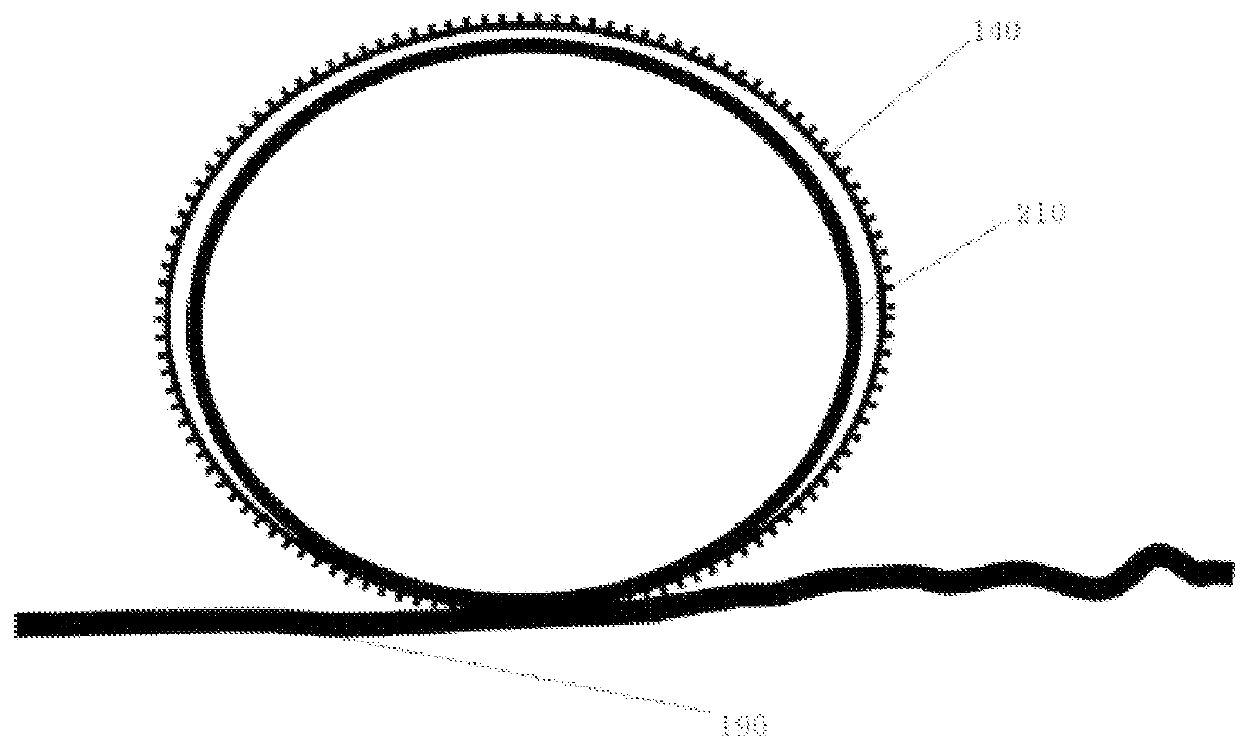

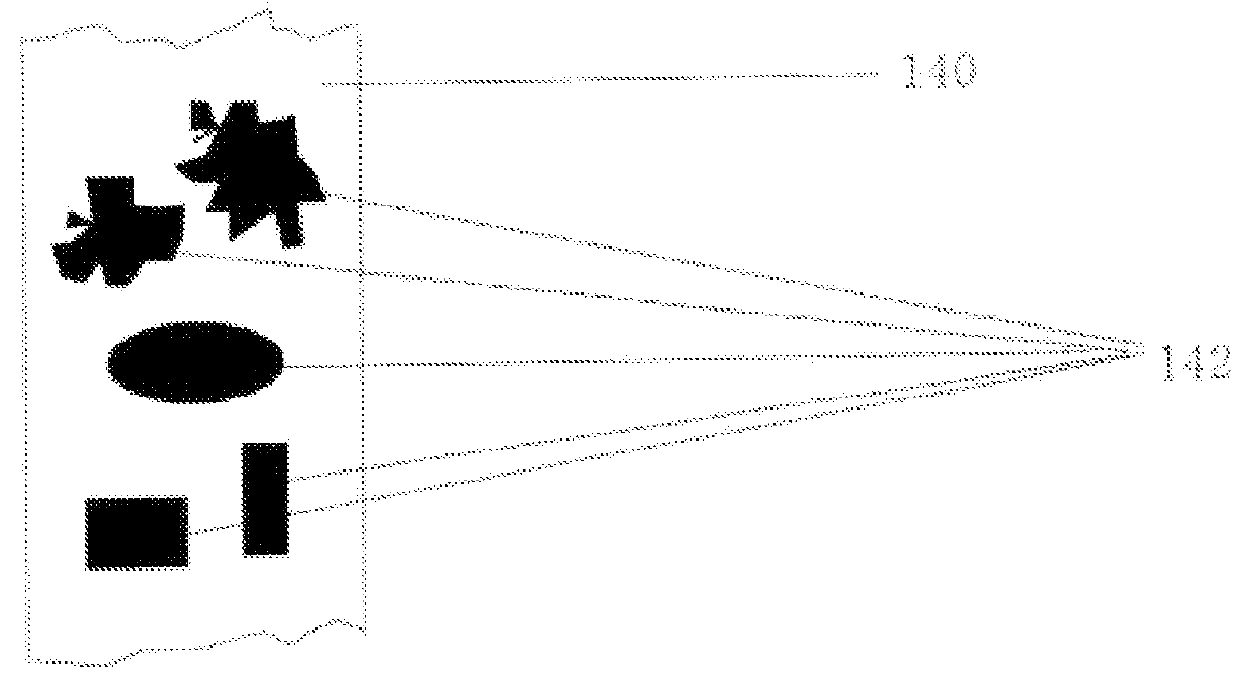

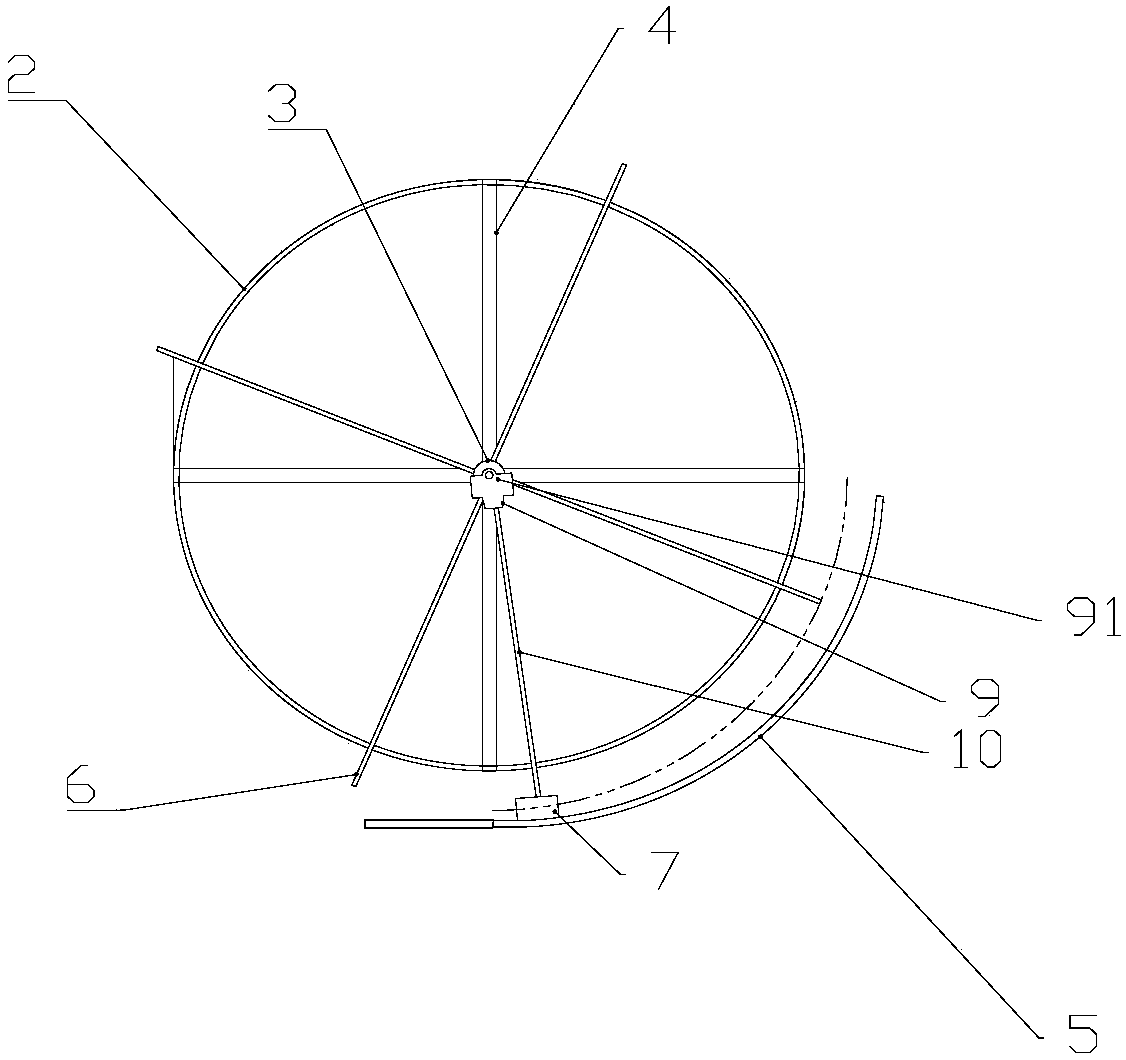

InactiveUS20160052353A1Improve overall utilizationReduce damage costsAuxillary traction increasing equipmentNon-skid devicesSpokeWheel and axle

The present invention discloses a nonslip device for preventing a vehicle from falling into a difficult situation causing the vehicle to be unable to move or be controlled because of slipping between the tires and the road, characterized by comprising: a fixing plate for fastening a nonslip circular flange onto the wheel axle or an aluminum wheel; a middle circular flange with a middle spoke assembly connected to a fixing circular flange formed perpendicular to the surface of the fixing plate so as to strengthen the nonslip circular flange by preventing it from being twisted or bent; a resilient body part arranged between the middle circular flange and a frictional circular flange for imparting resilience to the nonslip circular flange, the frictional circular flange enhancing the frictional resistance to a slippery road surface; and an assisting device for quickly and easily mounting the device to the vehicle.

Owner:JUNG SANG GWANG

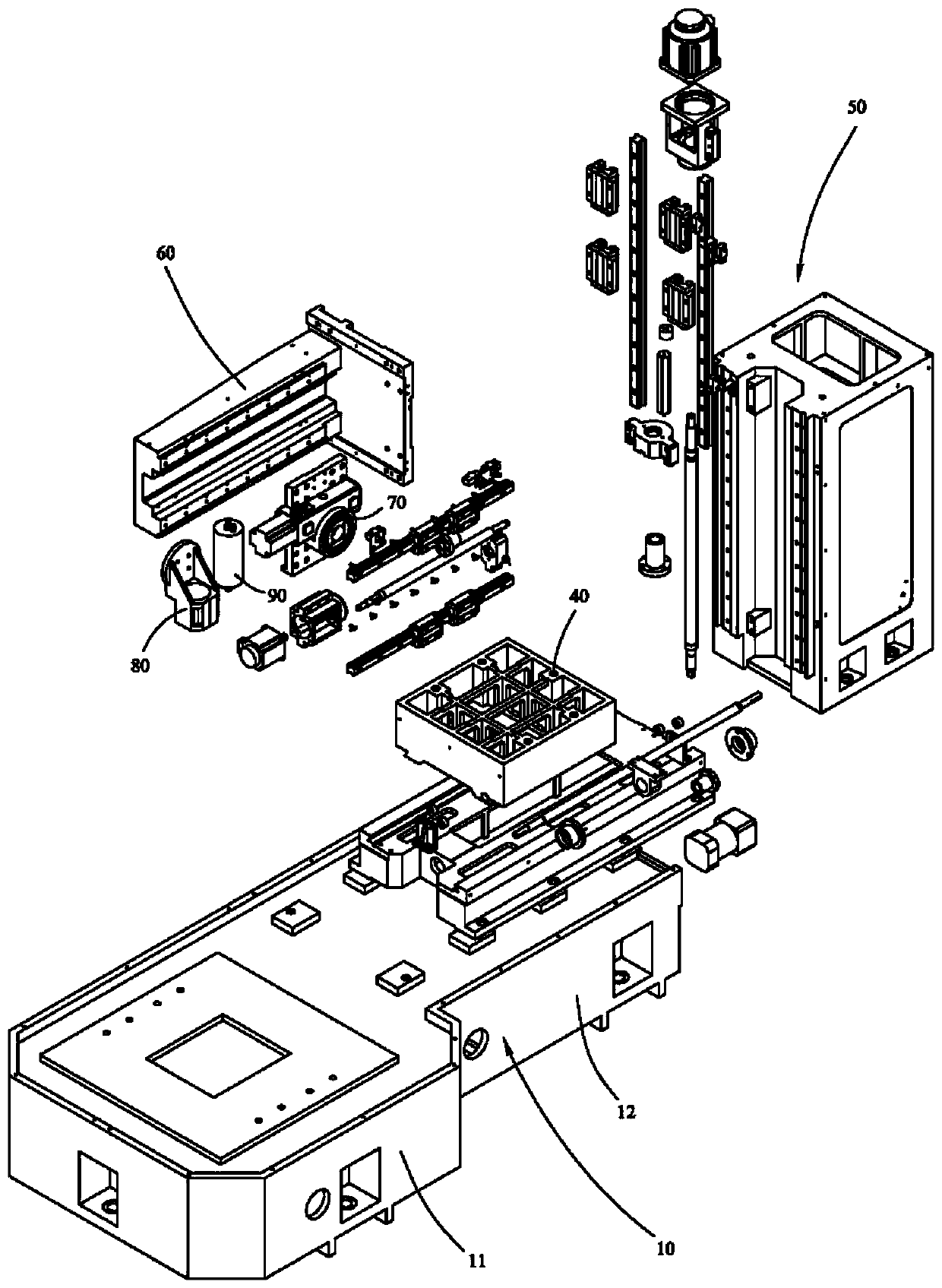

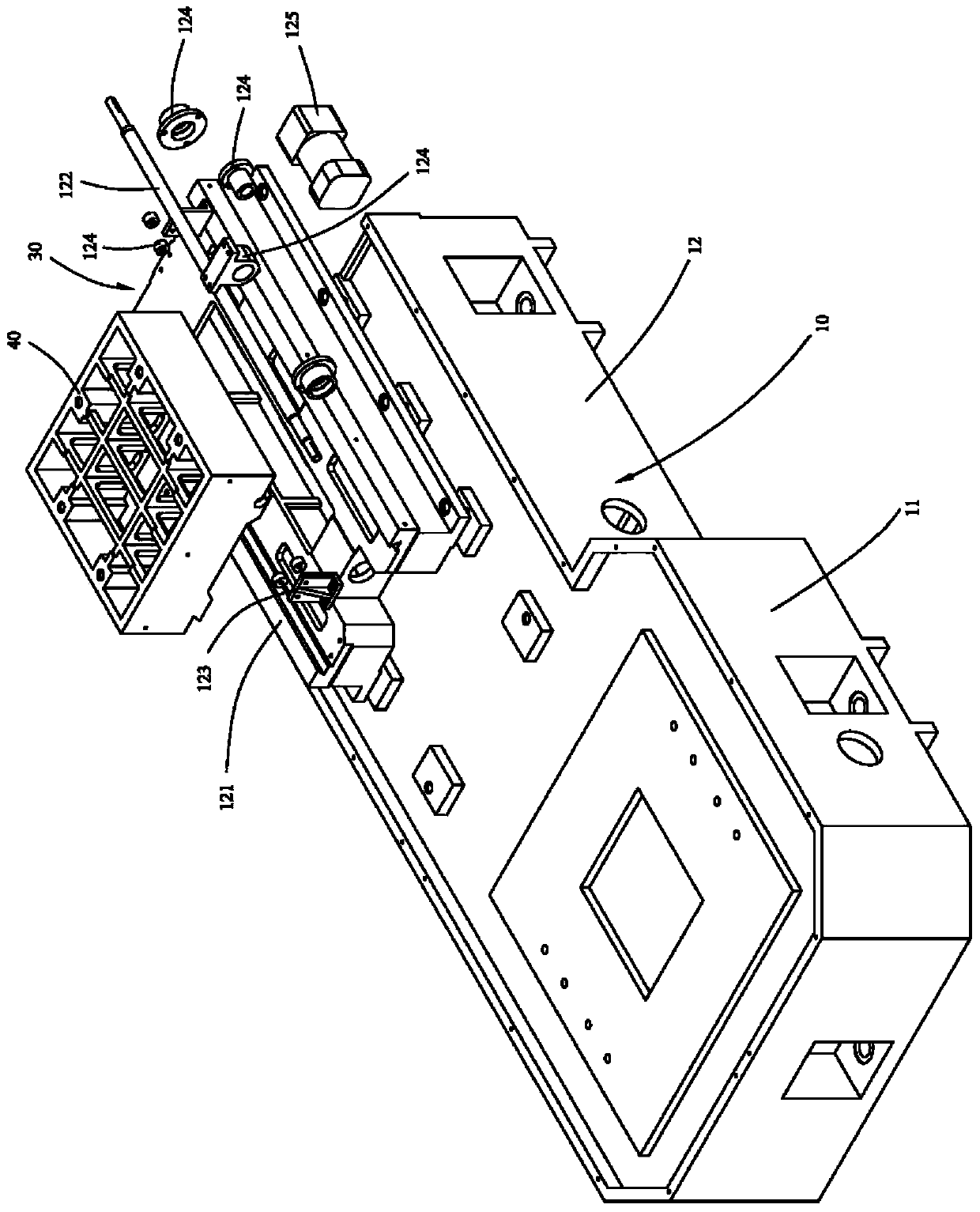

Material sheet conveying equipment and material sheet detection method

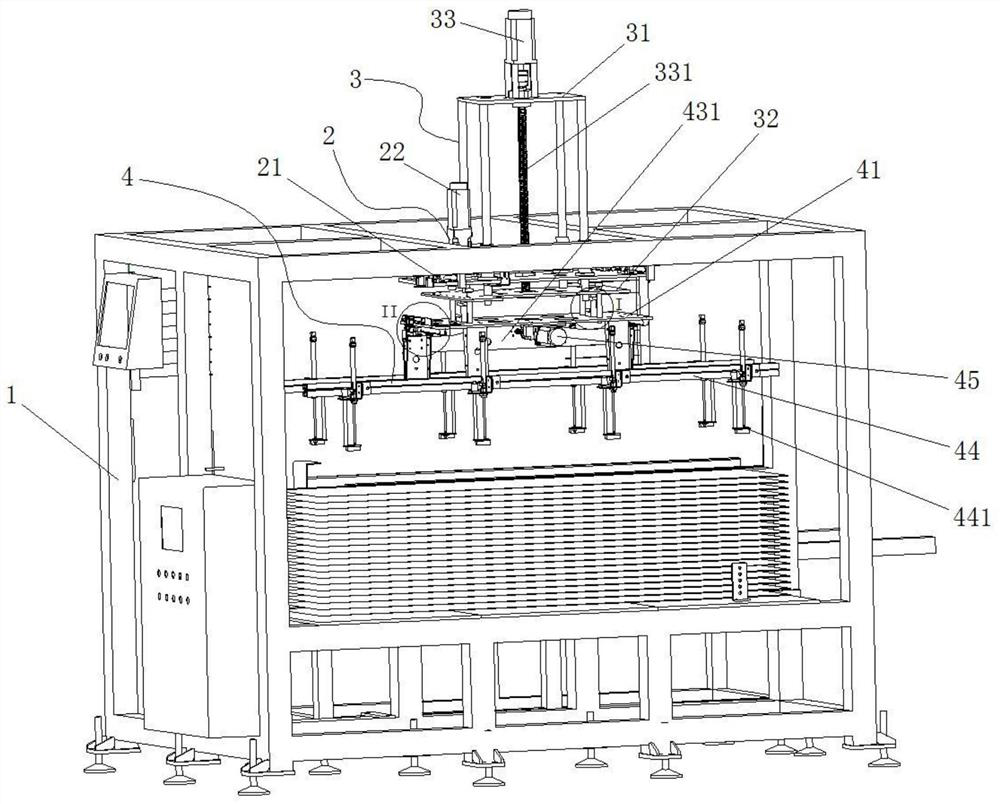

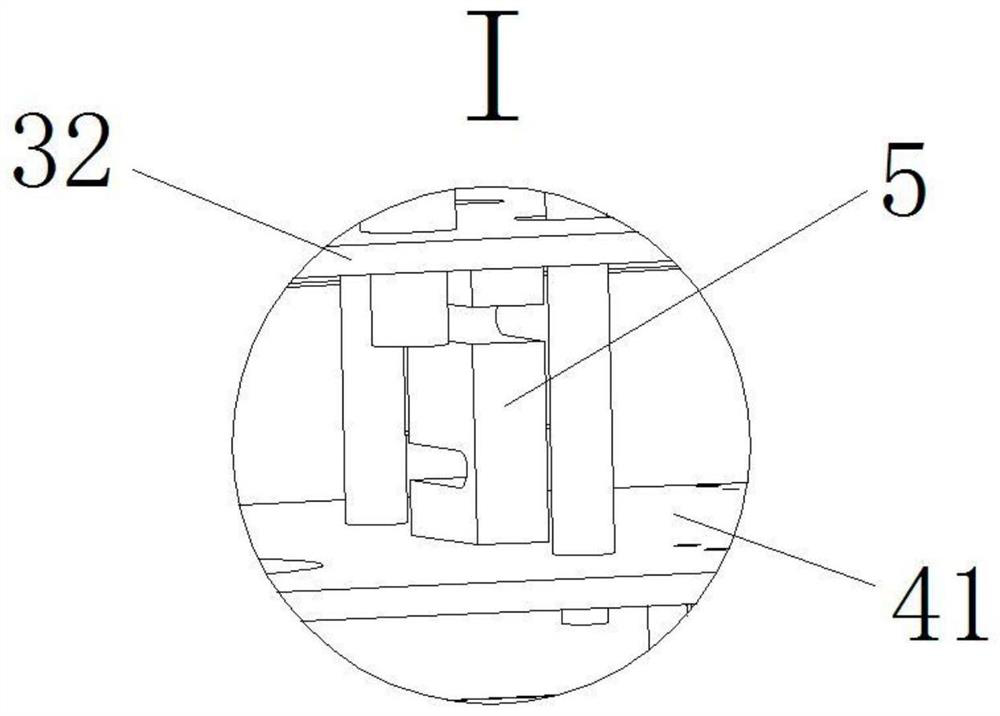

InactiveCN112722844AReduce scrap costsReduce damage costsConveyorsMetal-working feeding devicesRobot handEngineering

The invention provides material sheet conveying equipment which comprises an equipment main body frame. A mechanical arm translation mechanism, a mechanical arm lifting mechanism and a mechanical arm material taking mechanism are arranged in the equipment main body frame; the mechanical arm lifting mechanism is installed on the mechanical arm translation mechanism and is driven by the mechanical arm translation mechanism to translate; the mechanical arm material taking mechanism is installed on the mechanical arm lifting mechanism and is driven by the mechanical arm lifting mechanism to ascend and descend; a weighing sensor is arranged between the mechanical arm lifting mechanism and the mechanical arm material taking mechanism; and the material taking state is detected through the weighing sensor. According to the material sheet conveying equipment and the material sheet detection method provided by the invention, through ingenious design, the weighing sensor is arranged between the mechanical arm lifting mechanism and the mechanical arm material taking mechanism, so that the weight change during material taking can be detected, whether material taking is normal or not can be accurately judged, the production efficiency is improved, and meanwhile, the material scrap cost and the stamping die damage cost are saved.

Owner:苏州奥拓自动控制有限公司

Water vapor treatment part, shower head and cleaning system

InactiveCN112619913AReduce humidityReduce disease riskSpray nozzlesWater vaporEnvironmental engineering

The invention discloses a water vapor treatment part, a shower head and a cleaning system, and relates to the field of cleaning. The cleaning system comprises the shower head, the shower head comprises a water vapor treatment part combined with the shower head; the air inlet end of the water vapor treatment part corresponds to the water outlet of the shower head, or the air inlet end and the air outlet end of the water vapor treatment part respectively correspond to the water outlet of the shower head; the water vapor treatment part comprises a shell, a driving device, an impeller and a flow guide device, wherein the driving device is fixedly arranged in the shell, and the output end is connected with the impeller; and the flow guide device is used for guiding and separating water vapor, establishing a fluid channel and establishing a fluid channel cooperating with the impeller. The air humidity is reduced during cleaning activity, so that the comfort level of a user is improved, the temperature difference generated by ventilation and dehumidification is reduced, the disease risk of the user is reduced, dehumidification is conducted close to the water outlet of the shower head, energy consumed by dehumidification work is saved, the probability of bacterium breeding is reduced, and the bathing comfort level of the user is improved.

Owner:赵莉莉

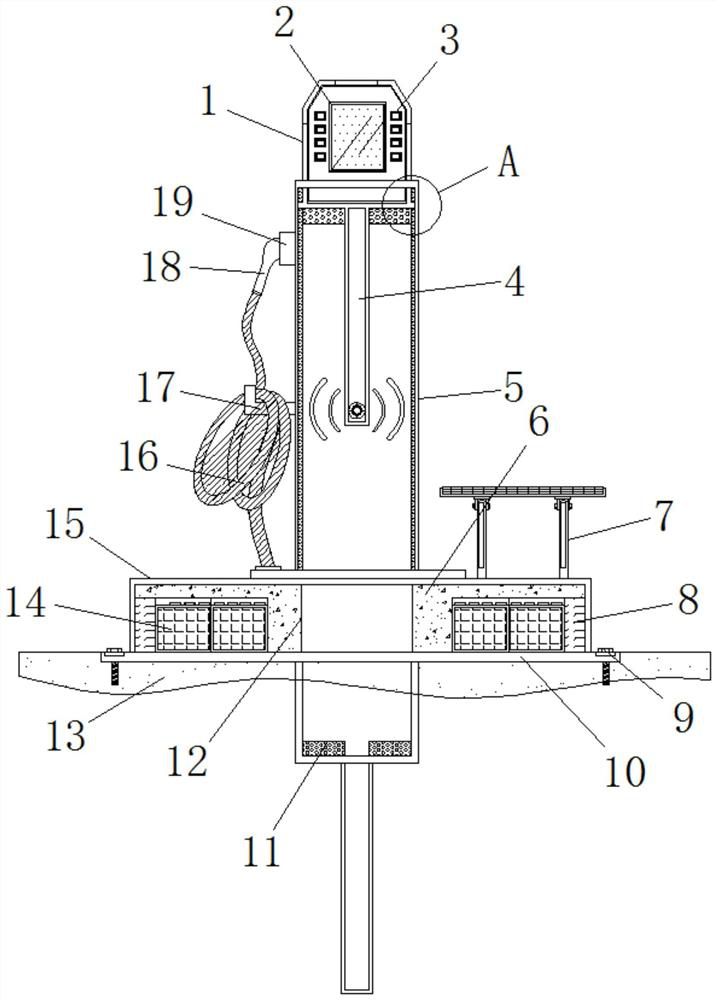

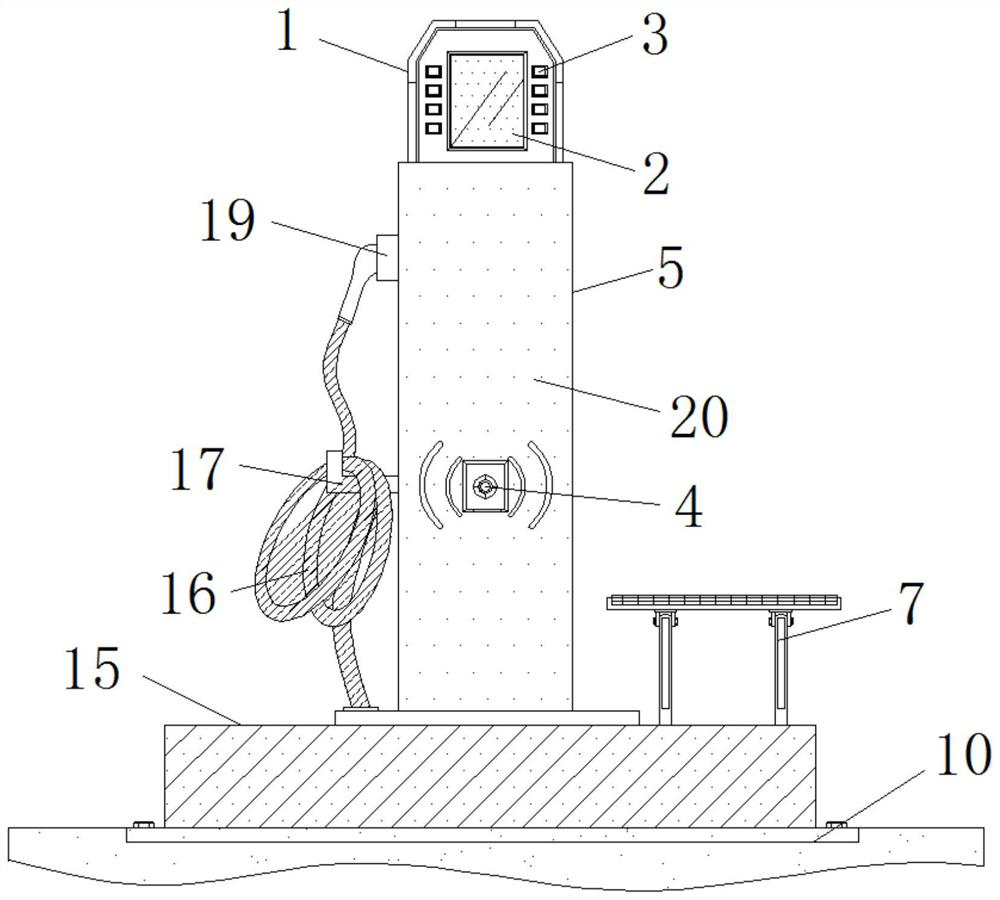

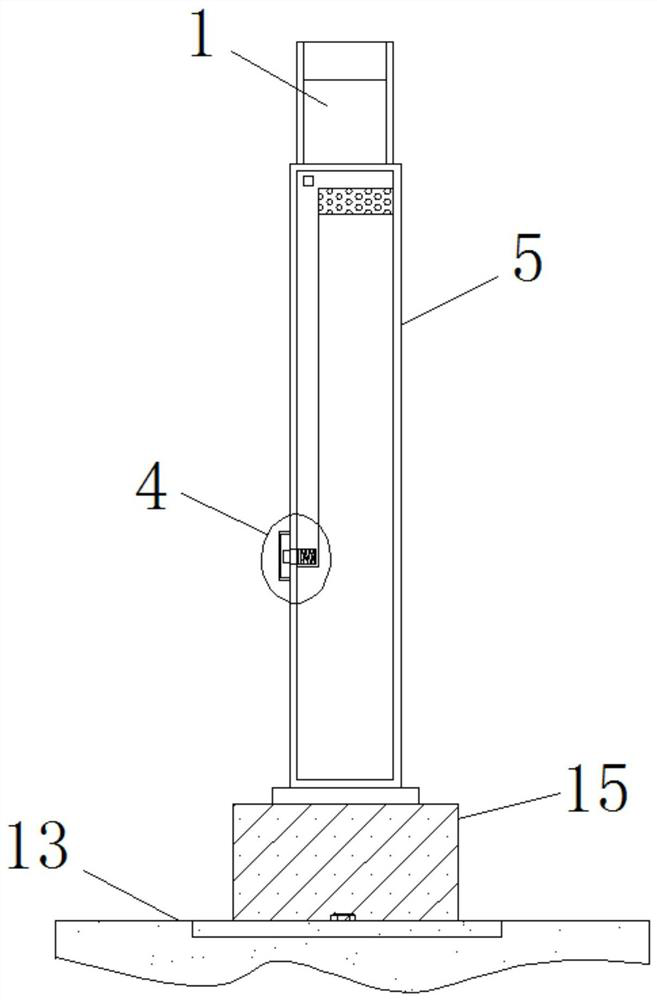

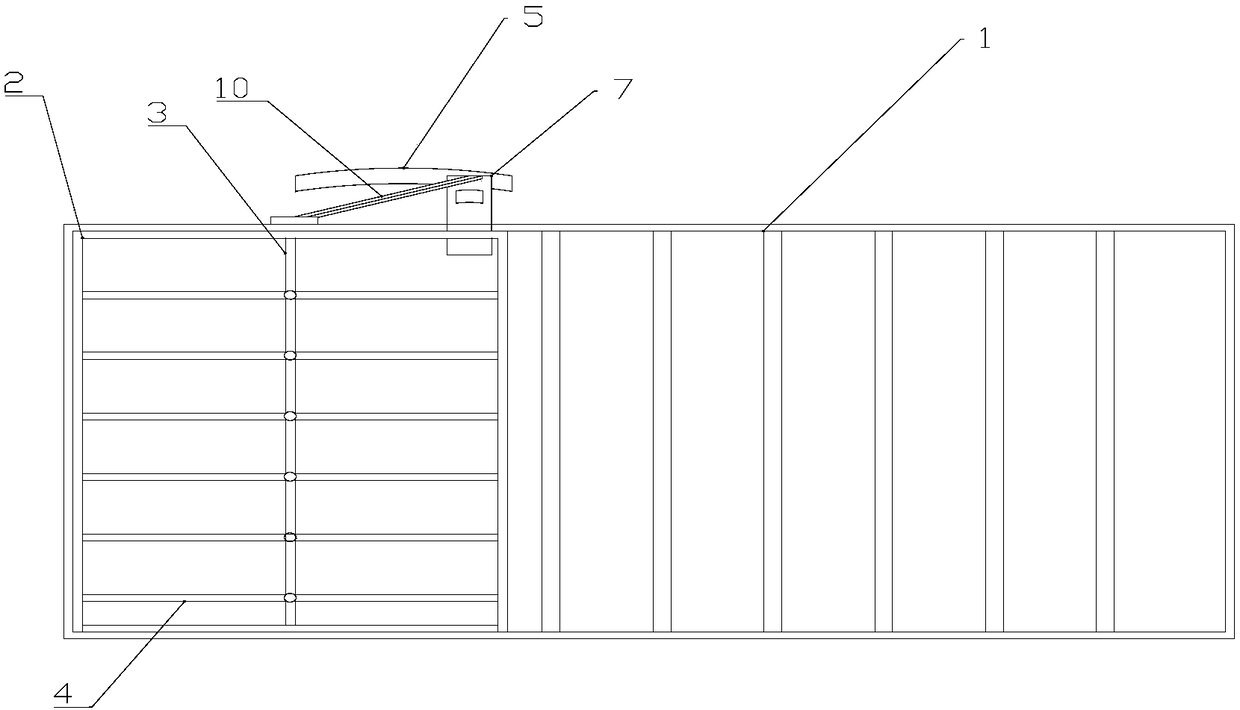

A new energy vehicle charging pile with energy saving function

ActiveCN112590588BAvoid damageNo damagePhotovoltaic supportsCharging stationsNew energyStructural engineering

The invention discloses a charging pile for a new energy vehicle with an energy-saving function, comprising a main body, a casing, a bottom plate and a protective steel cover, and the top of the casing is movably connected with the main body. In the present invention, a self-protection structure is installed at the bottom end of the main body, and when the car makes a mistake in reversing or collides with the charging pile shell in an emergency, the contact height of the impacted vehicle is flush with the protective cover, and the protection When the cover collides, it is pressed against the snap-on block provided inside, so that it retracts into the inner groove through the action of the elastic ring, so that the main body and the shell can fall quickly inside the shell after losing the fixed connection. The setting of the retaining groove is connected with the reserved structure connected to the bottom of the bottom plate to complete the fall protection. When falling, the buffer pad installed at the bottom of the main body can contact the protective pad set inside the reserved structure, effectively hiding the falling to the ground and avoiding the charging pile. The main structure is damaged when it is hit, which effectively reduces the damage cost.

Owner:镇江领驭立方智能装备有限公司

Multi-mode access control passing system

PendingCN108564699AHigh precisionLow verification error rateTurnstilesIndividual entry/exit registersLocking mechanismEngineering

The invention relates to an access control system, in particular to a multi-mode access control passing system which comprises a door body, a rotating door sill and a door sill locking mechanism. Therotating door sill is mounted on the door body, and comprises a rotating shaft and a plurality of door panels mounted on the rotating shaft. A gear fixedly sleeves the rotating shaft. The door sill locking mechanism comprises a pawl matched with the gear and a retainer engaged with the gear. An exit channel and an entrance channel are arranged in the door body and at the rotating door sill. The exit channel is communicated with the outer side of the door body. The entrance channel is communicated with the inner side of the door body. The multi-mode access control passing system further comprises a human face image acquiring mechanism and a human face contact acquiring mechanism. The invention provides the system for passing through access control by adopting multiple verification modes.

Owner:CHONGQING HUIJU INTELLIGENT ELECTRONICS

A Low Temperature Alarm System for Resin Curing Drying Kiln for Resin Curing for Battery with Timely Loss Reduction

Owner:义乌市嘉诗电子科技有限公司

Mine vehicle in-out statistics device and method

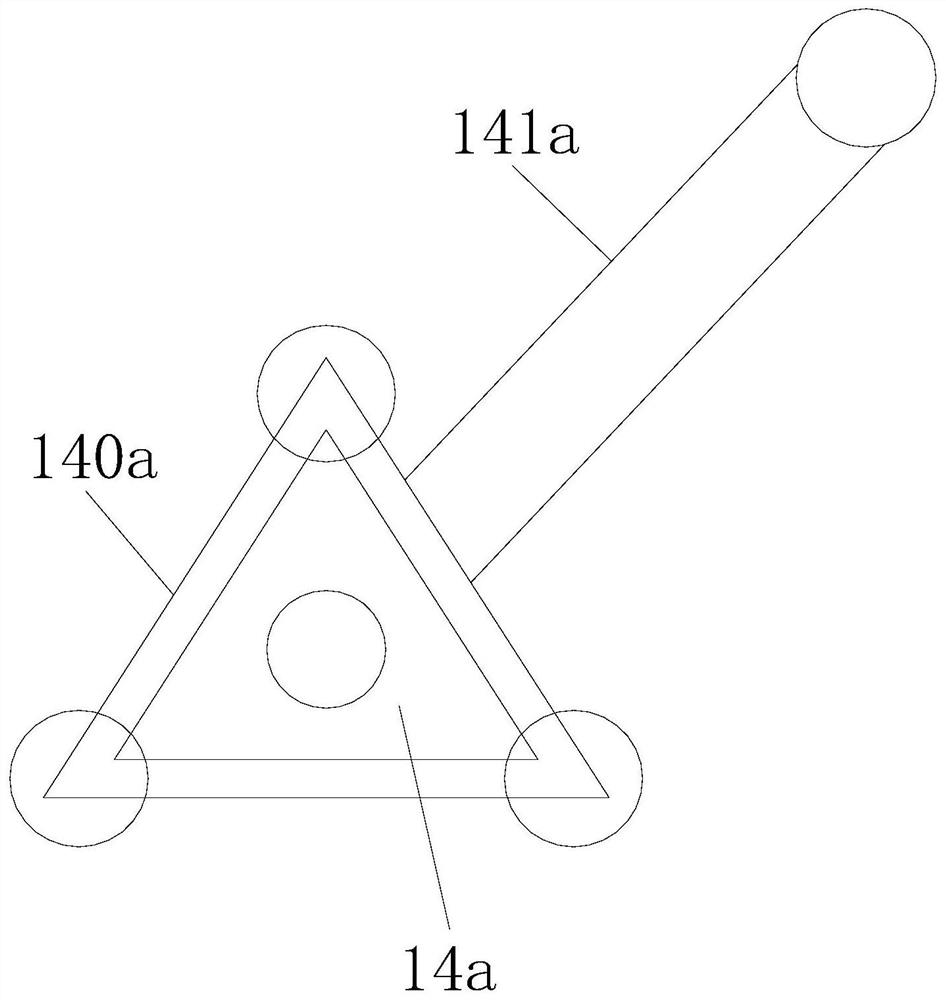

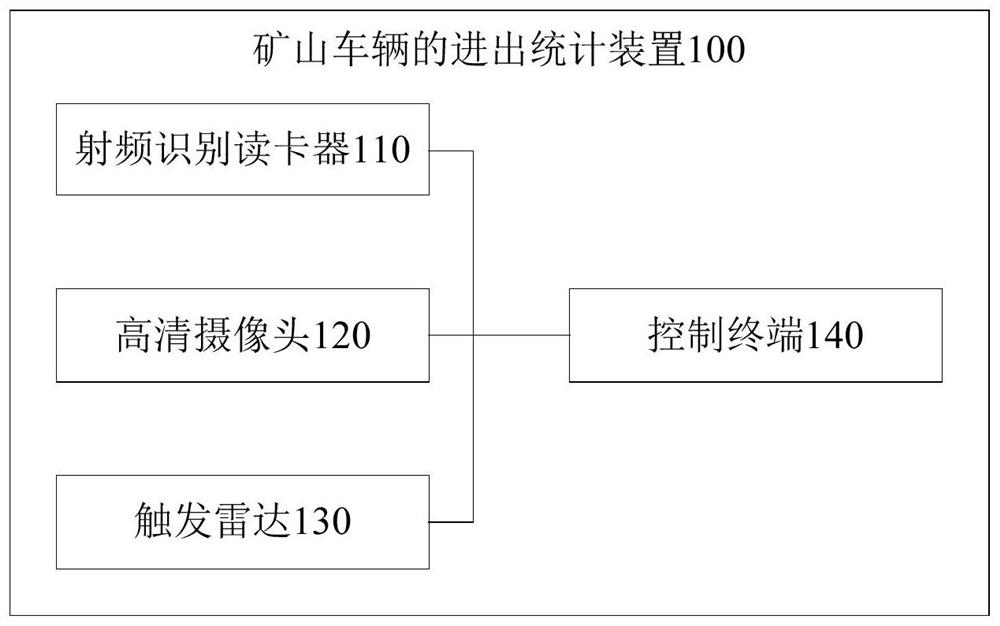

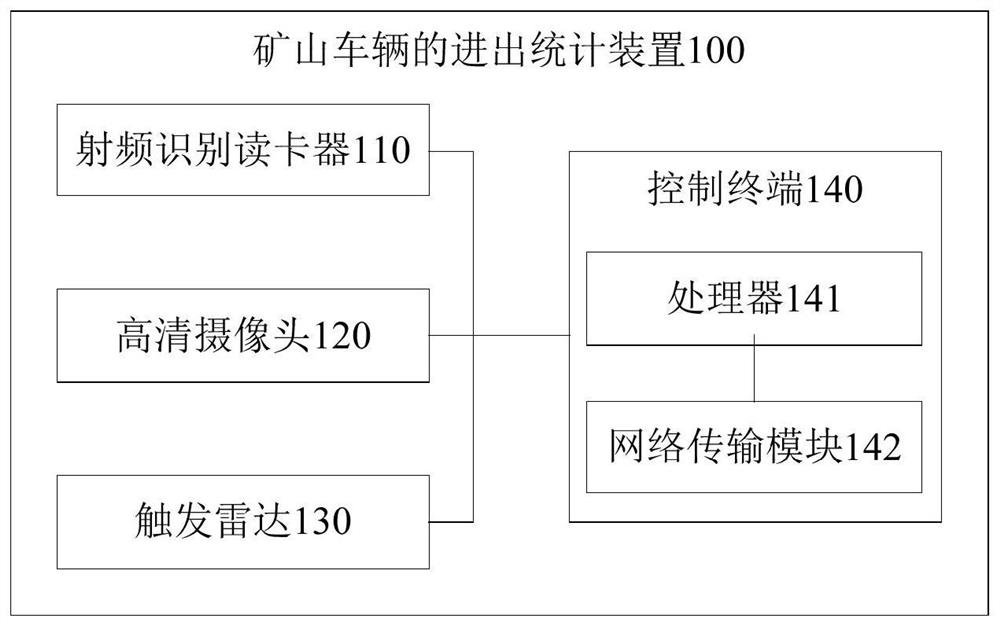

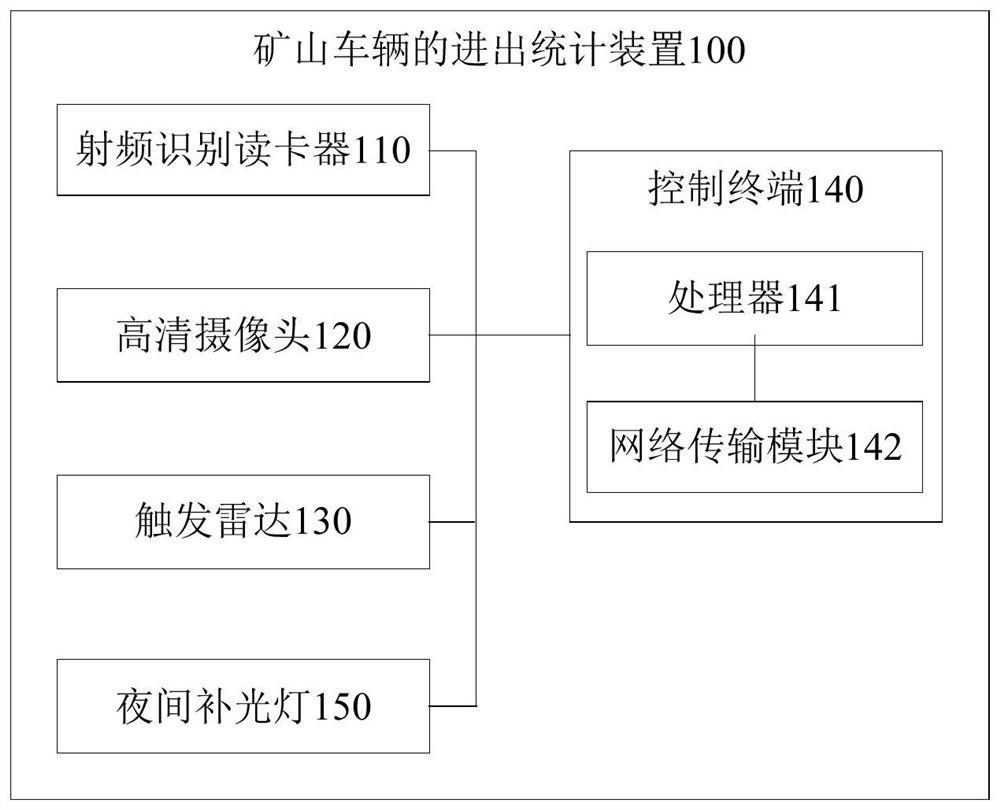

PendingCN111783553AReduce damage costsImprove supervision efficiencyCharacter and pattern recognitionSensing by electromagnetic radiationStatistical analysisRadar

The invention provides a mine vehicle in-out statistics device and method. The device comprises a radio frequency identification card reader, a high-definition camera, a trigger radar and a control terminal. When the radio frequency identification card reader reads the card number of the radio frequency tag card, the control terminal controls the trigger radar to perform radar positioning, acquires a trigger signal from the trigger radar, controls the high-definition camera to acquire a mine vehicle image according to the trigger signal, and uploads the acquired mine vehicle image to the server, so that the server performs statistical analysis on the unloading condition of the mine vehicle according to the received mine vehicle image. Therefore, statistical analysis is performed on the unloading condition of the mine vehicle according to the acquired mine vehicle image, so that the supervision efficiency of non-compliant conditions such as empty running or insufficient running in the operation process of the surface mine vehicle is improved, the oil consumption and the vehicle damage cost are saved for users, and meanwhile, the labor cost is saved.

Owner:东方浩联(北京)智能科技有限公司

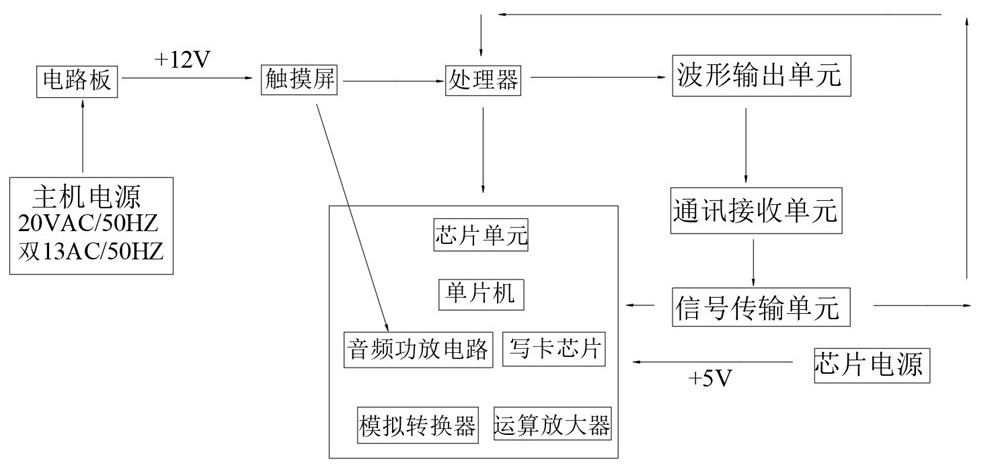

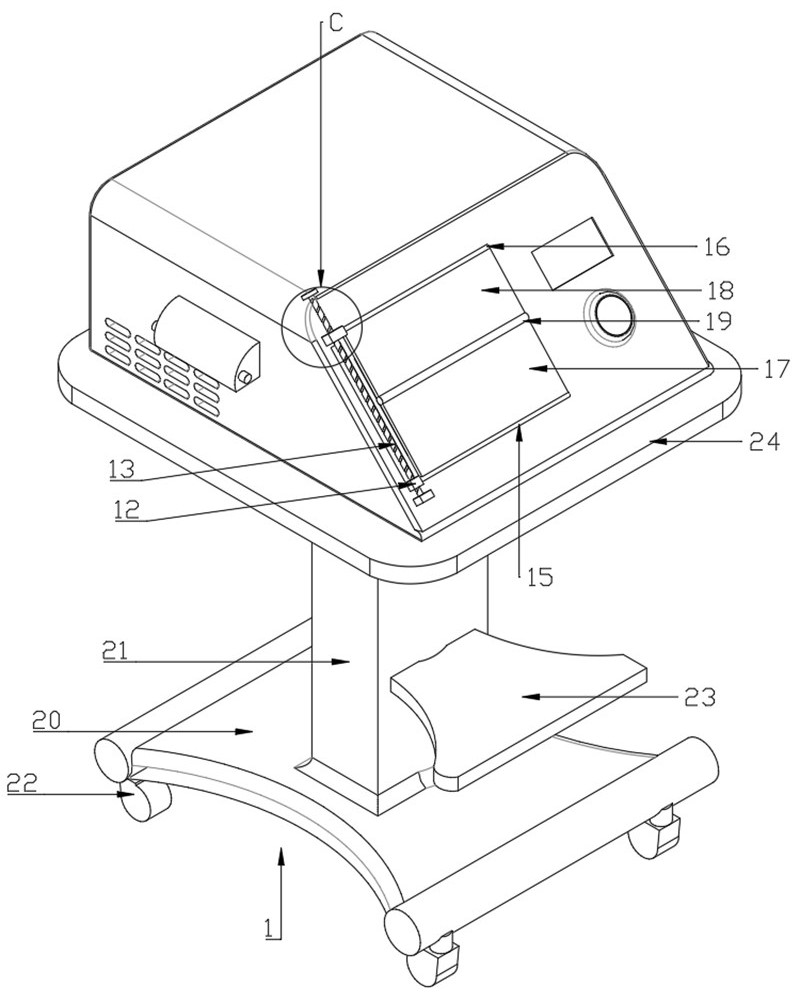

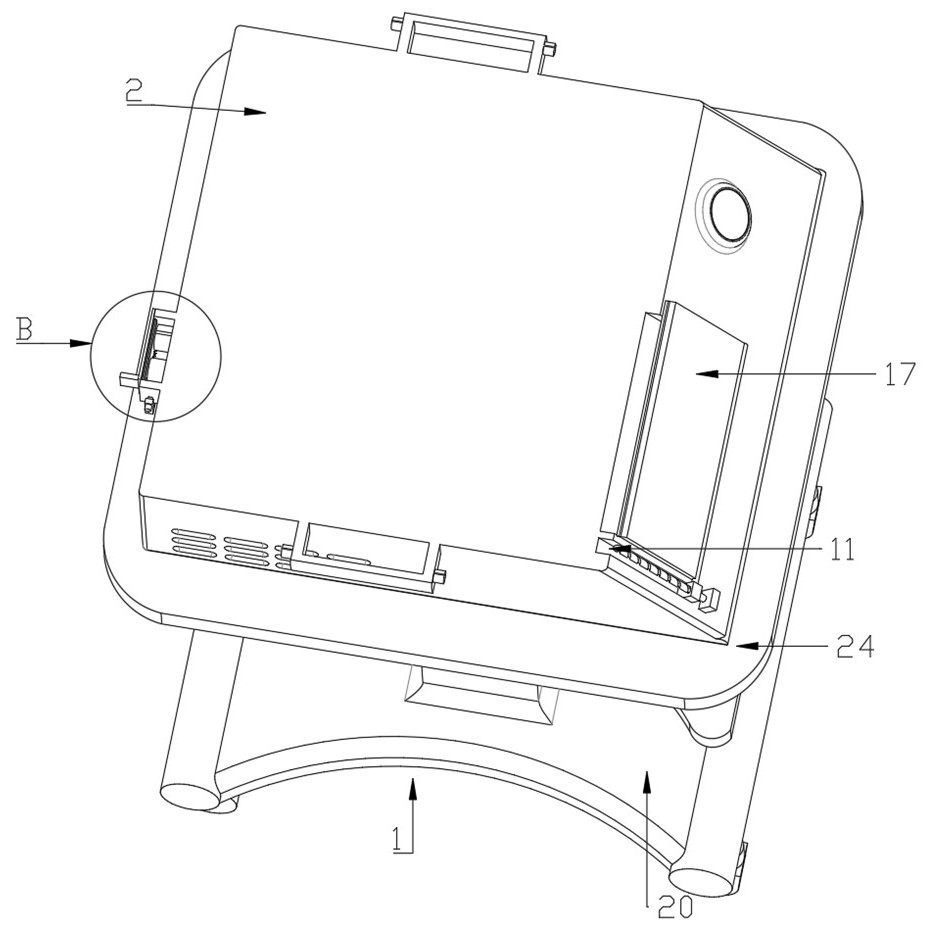

Waveform control system and copper therapy instrument with good protectiveness thereof

PendingCN113209472ATo promote metabolismReduce power consumptionElectrotherapyArtificial respirationCapacitanceSquare waveform

The invention discloses a waveform control system and a copper therapy instrument with good protectiveness thereof, and relates to the technical field of copper therapy instruments. The waveform control system comprises a touch screen; the touch screen is electrically connected with a circuit board; the touch screen is connected with a processor; the processor is connected with a waveform output unit; the waveform output unit is used for controlling the copper therapy instrument to generate pulse waveforms; the waveform output unit is connected with a communication receiving unit, and the communication receiving unit is connected with a signal transmission unit; the signal transmission unit is connected with a chip unit; and the processor is in capacitor connection with the chip unit. By arranging the chip unit, the chip unit controls the cooperation of a plurality of chips, so that the effects of low power consumption, high efficiency, rapidness, safety and stability are achieved, and square waves with a certain frequency are output, so that external execution elements are controlled, body metabolism is promoted, detoxification and beautifying are achieved, and body building is achieved.

Owner:诗颜医疗科技(东莞)有限公司

Contact type limiting device of coke pusher

ActiveCN112831327AAvoid influenceEasy to useCoke oven safety devicesElectro hydraulicStructural engineering

The invention discloses a contact type limiting device of a coke pusher. The device comprises a coke pushing rod, a base and a coke oven, wherein one side of the coke pushing rod is fixedly connected with a first electric hydraulic rod, the upper end of the base is fixedly connected with a supporting plate, the upper end of the supporting plate is fixedly connected with a second electric hydraulic rod, one side of the coke pushing rod is provided with a limiting assembly, a protective cover is fixedly connected to one side of the coke oven, a limiting switch is arranged in the protective cover, the push rod corresponds to the limiting switch, and an L-shaped limiting rod is fixedly connected to the outer wall of the coke pushing rod. When the device is in use, the stroke of the coke pusher is controlled by the limiting switch, and the limiting switch is in the protective cover so that influences of high temperature and dust on the limiting switch are avoided; the damage to the limiting switch is reduced by arranging the limiting assembly with a buffering function, the coke pushing rod can be lifted, and the coke pushing device is convenient to maintain and use.

Owner:西藏驰程环保科技有限公司

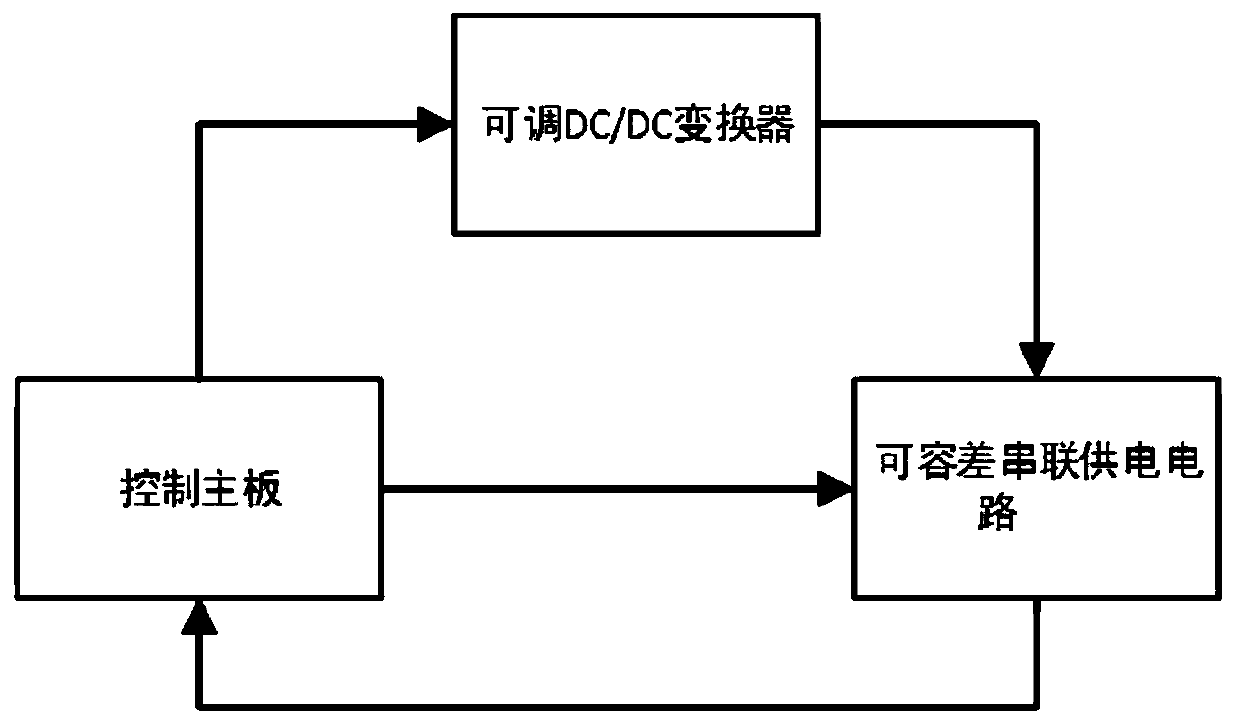

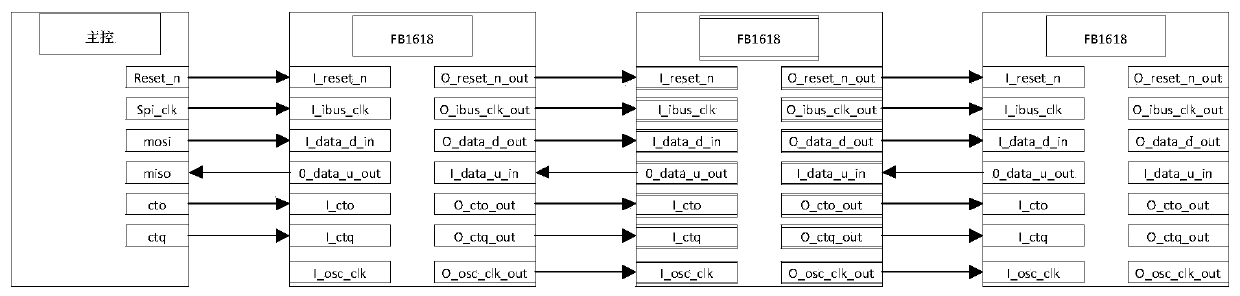

Tolerance high-power-density series power supply device, and method thereof

PendingCN110308781AAvoid paralyzing technical issuesReduce damage costsVolume/mass flow measurementPower supply for data processingDamage costHigh power density

The invention provides a tolerance high-power-density series power supply device and a method thereof. The tolerance high-power-density series power supply device comprises a control main board, an adjustable DC / DC converter and a tolerance series power supply circuit, wherein the control main board and the adjustable DC / DC converter are controlled in a master-slave mode; the control main board and the tolerance series power supply circuit are in two-way communication; and the adjustable DC / DC converter is in power connection with the tolerance series power supply circuit. The invention aims to provide a tolerance series power supply circuit, wherein barrier points can be automatically shielded in operation, and the damage cost can be reduced, and the circuit structure can effectively provide higher power density, so that the design and production can be optimized.

Owner:深圳大锄科技有限公司

Apparatus for removal of docking plate in semiconductor equipment

ActiveUS20120235338A1Efficient methodUnexpected effectPositioning apparatusMetal-working holdersMarine engineeringSemiconductor

The present invention relates to an apparatus for removal of docking plate, wherein comprising a docking plate base device; and a handle removably joined to the docking plate base device and causing the docking plate base device to be removed from the semiconductor equipment when the handle is joined to the docking plate base device.

Owner:MACRONIX INT CO LTD

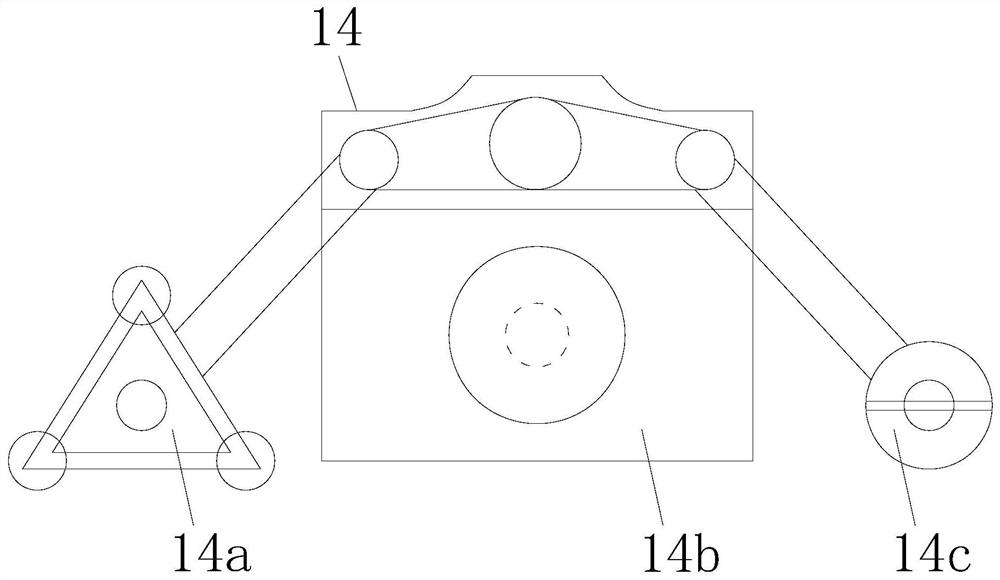

A palletizing robot

ActiveCN110525718BWeaken Rigid CollisionReduce bumpsShock-sensitive articlesRobot handMachine building

The invention belongs to the technical field of mechanical manufacturing, specifically a palletizing manipulator; including a rotating bracket, a control box, a rotating arm and a grabbing unit; the control box is installed at the end of the rotating bracket to control the work of the entire manipulator; The rotary arm is installed at the output end of the control box; the grabbing unit is hinged at the end of the rotary arm, and the grabbing unit includes a connecting rod, a grabbing platform and a clamping assembly; the clamping assembly includes a screw wheel, a piston cylinder, a clamping rod and Shaping teeth; through the cooperation of the rotating bracket, the control box, the rotating arm and the grabbing unit, the stacking and moving of the tiles can be realized to reduce the collision of the tiles. The rigid collision generated during the clamping process reduces the situation of tiles being bumped, improves the working efficiency and effect of the manipulator, reduces the damage cost during the tile processing process, and reduces a lot of manpower and material resources.

Owner:重庆智能电控技术有限责任公司

A contact limit device for coke pusher

The invention discloses a contact-type limiting device for a coke pusher, which comprises a coke pusher rod, a base and a coke oven. One side of the coke pusher rod is fixedly connected with a first electrohydraulic rod, and the upper end of the base is fixedly connected with a A support plate, the upper end of the support plate is fixedly connected with a second electro-hydraulic rod, one side of the coke pushing rod is provided with a limit assembly, one side of the coke oven is fixedly connected with a protective cover, and the inside of the protective cover A limit switch is set, the ejector rod and the limit switch are set correspondingly, and an L-shaped limit rod is fixedly connected to the outer wall of the coke pushing rod. And the limit switch is located inside the protective cover, avoiding the influence of high temperature and dust on the limit switch, and by setting the limit component with buffer function, the damage to the limit switch is reduced, and the focus pusher can also be adjusted. Lifting, easy maintenance, very convenient to use.

Owner:西藏驰程环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com