Four-shaft character carving machine for tire molds and character carving method thereof

A technology of tire molds and cutting plotters, which is applied in the fields of processing models, decorative arts, etc., to achieve the effects of reducing mold damage costs, improving work efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The lettering on the four-axis tire mold of the present invention reduces the time cost of the customer and the mold damage cost caused by human factors, and improves the overall work efficiency and product qualification rate.

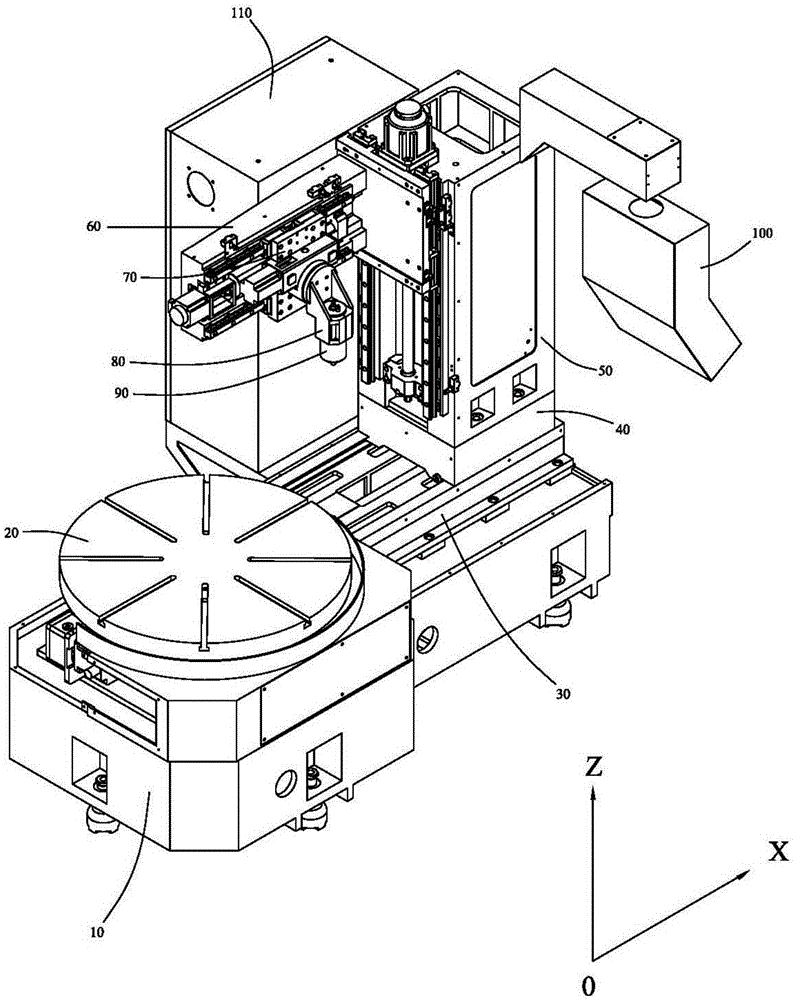

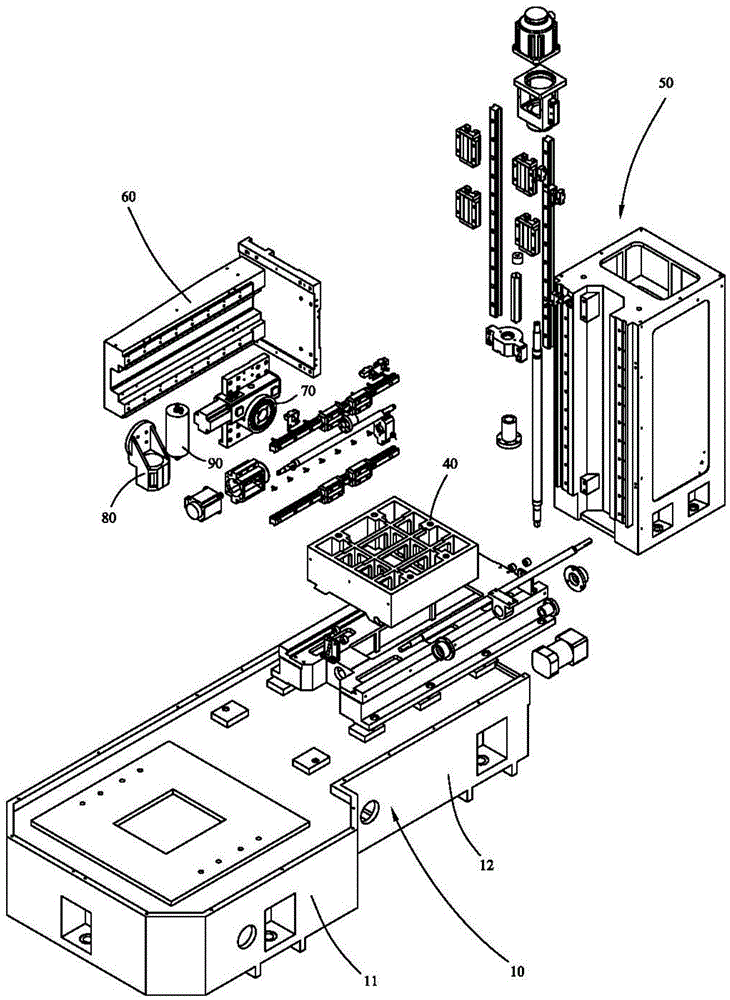

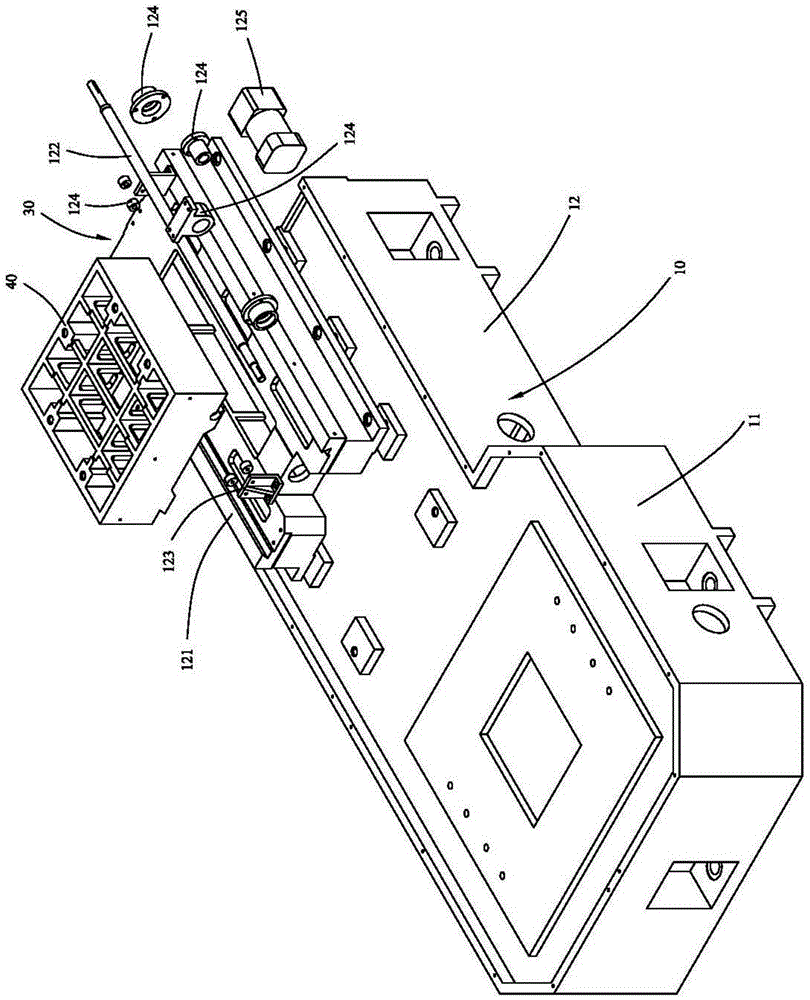

[0028] The invention discloses a four-axis tire mold cutting plotter, such as figure 1 As shown, the four-axis tire mold cutting plotter includes: a base 10, a rotary table 20 located at one end of the base 10, a column base 30 located at the other end of the base 10, and a column slider 40 slidably fixed on the column base 30 , the column 50 fixed on the column slide seat 40, the main shaft saddle 60 slidably fixed on one side of the column 50, the 125 rotary index plate 70 slidably fixed on the main shaft saddle 60, fixed on the 125 The main shaft coupling seat 80 at the end of the rotary index plate 70, the water-cooled electric spindle 90 located in the main shaft coupling seat 80, the display 100 hanging outside the column 50, and the four-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com