Wheel adjusting mechanism of high-speed embroidery equipment for textile manufacturing and processing

An adjustment mechanism and textile technology, which is applied in the field of textile equipment, can solve the problems that the adjustment structure cannot be easily disassembled, the movement distance of the treasure wheel cannot be controlled, and the adjustment structure cannot be disassembled, maintained, and replaced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

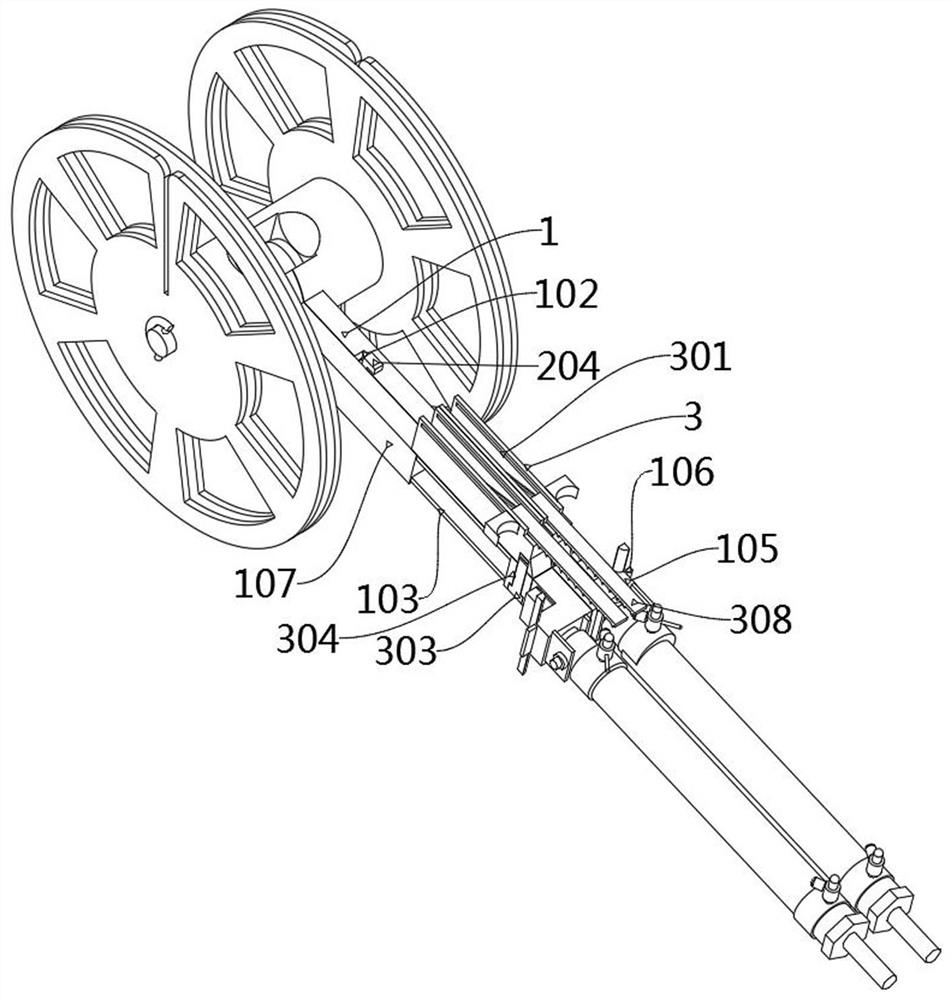

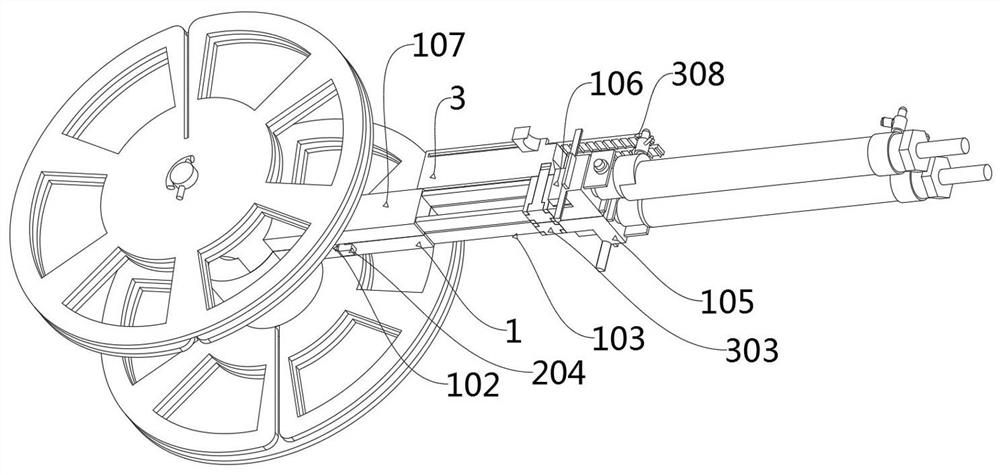

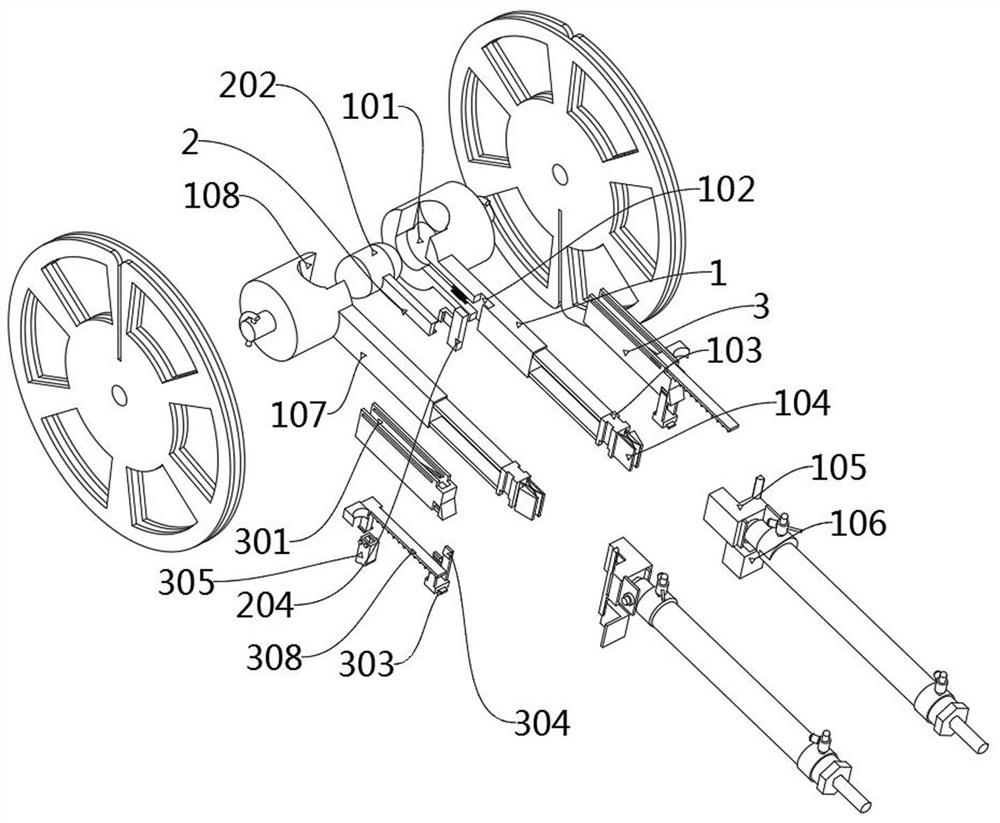

[0028] as attached figure 1 to attach Figure 8 Shown:

[0029]The invention provides a treasure wheel adjustment mechanism for textile manufacturing and processing high-speed embroidery equipment, including a main body 1; the main body 1 is an L-shaped structure, and the left end of the main body 1 is a cylindrical structure, and a treasure wheel is installed on the outside of the left end of the main body 1 through a bolt and a shaft , the inner side of the main body 1 is installed with an installation part 2, and the upper right end of the main body 1 is installed with an adjustment part 3. The main body 1 plays the role of connecting with the treasure wheel and moving together, so that the treasure wheel can move together; the installation part 2, the installation part 2 The right end is installed with a limit mechanism, the mounting part 2 is a rectangular plate structure, and the mounting part 2 is embedded in the left end of the card slot 102, and the mounting part 2 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com