Yuba production apparatus based on slurry returning system hydraulic pressure

A production device and adjustable technology, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as differences in shapes, ingredients, tastes and cooking methods, damage to the pump 3, economic losses, etc., to achieve clear principles and reduce Effects of pressure and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

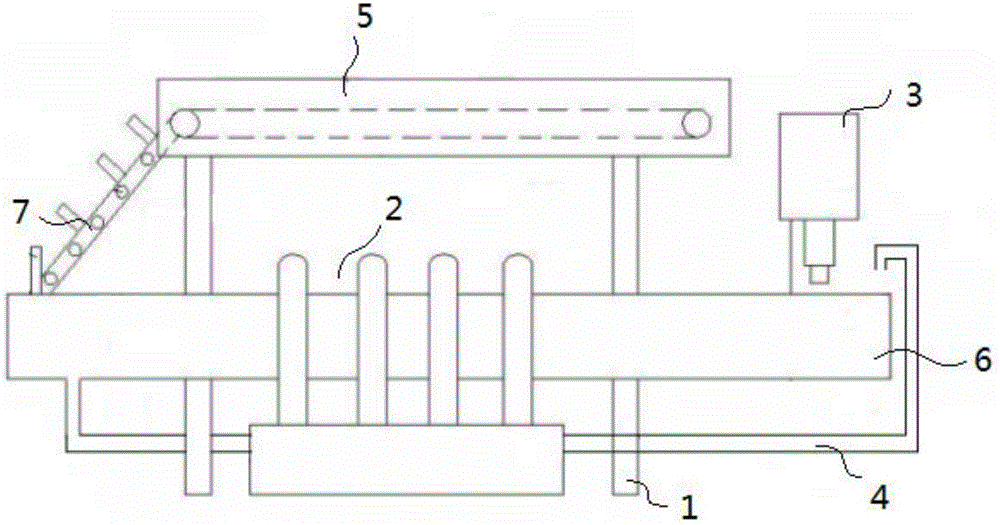

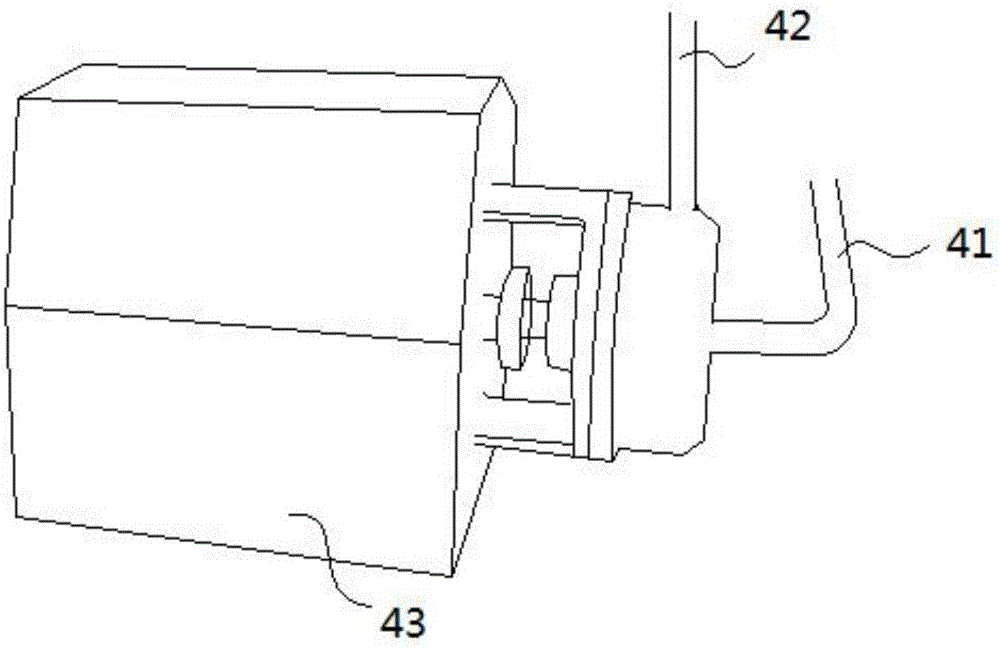

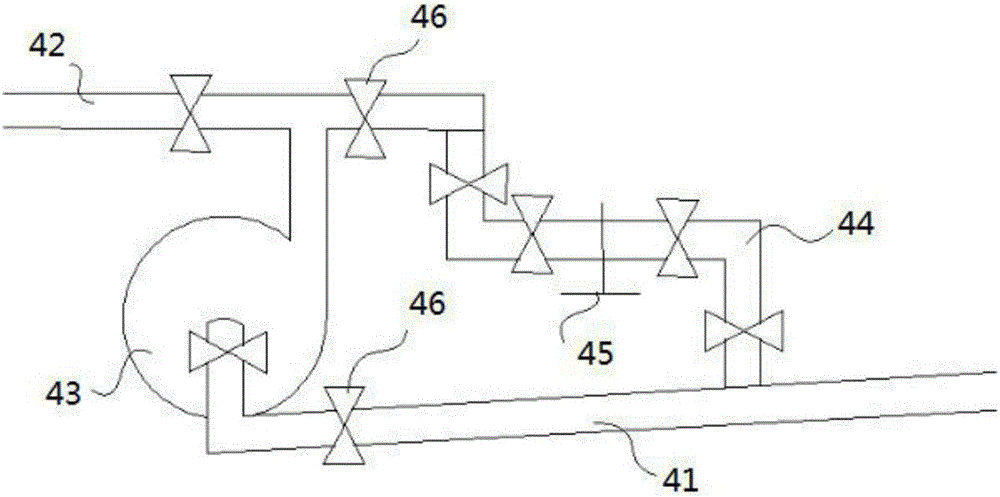

[0029] Such as figure 1 , image 3 As shown, a kind of bean curd stick production device based on the hydraulic pressure of the adjustable slurry return system of the present embodiment includes a tofu skin production unit, and the tofu skin production unit includes a frame 1, a skinning system 2, a slurry feeding system 3, and a slurry return system 4. Drying system 5 and bean curd stick shrinking system 7, frame 1 includes upper and lower layers, crusting system 2 is located on the lower layer of frame 1, drying system 5 is located on the upper layer of frame 1, pulp feeding system 3 is located in the crusting system 2, the bean curd stick shrinkage system 7 is located at the rear end of the crusting system 2, and the slurry returning system 4 is located at the bottom of the crusting system 2; the crusting system 2 includes a crusting tank 6, and the slurry returning system 4 includes a slurry returning system Pipeline 41, slurry delivery pipeline 42 and slurry pump 43, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com