Push-broaching molding process of gear part of ring gear

A technology of inner ring gear and tooth part, which is applied in the technical field of inner ring gear tooth part forming, can solve the problems of poor rigidity of broach, large axial radial ratio, low strength, etc. The effect of short and low damage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

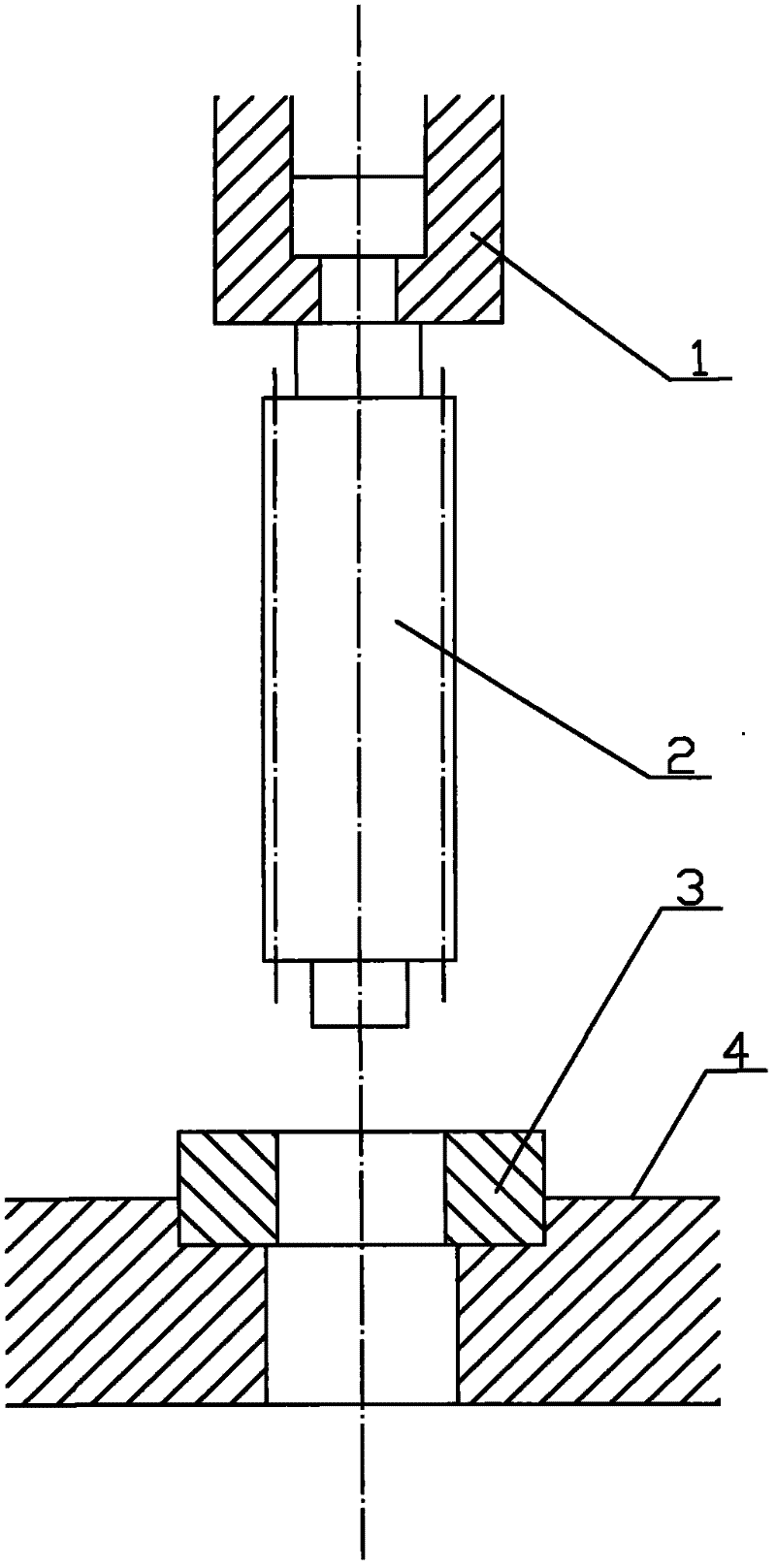

[0018] The present invention will be further described below according to the accompanying drawings and examples.

[0019] Accompanying drawing is the schematic diagram of embodiment of the present invention, and its technological process is as follows:

[0020] (1) First, position and install the flat inner ring gear 3 on the workbench 4;

[0021] (2) Vertically install push knives 2 of set sizes on the press head 1 of the press according to the sequence number, the push knives 2 are coaxial with the inner ring gear 3, the small end is located at the bottom end, and the large end is located at the upper end;

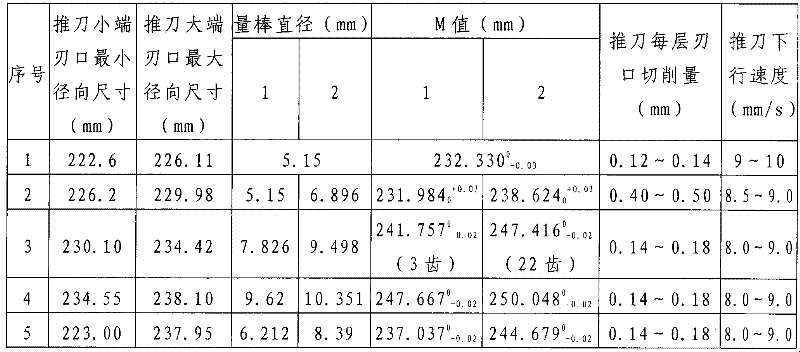

[0022] (3) When pushing, the thrust direction of the pressure head 1 acting on the upper end of the push knife 2 is consistent with the downward direction of the push knife 2, the downward speed of the push knife is 8 ~ 10mm / s, and the cutting amount of each layer of the push knife is 0.12mm ~ 0.50mm;

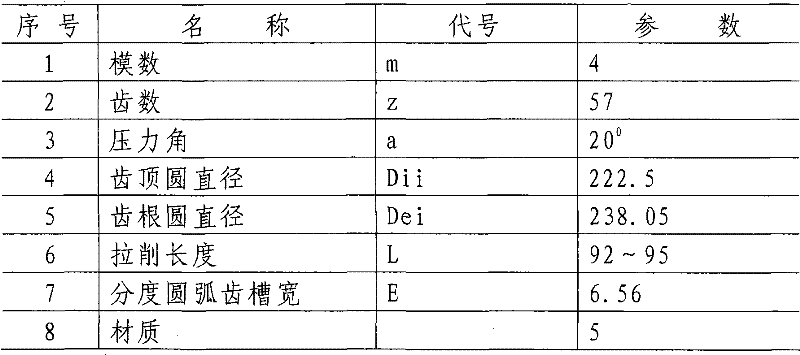

[0023] This embodiment is to push and cut the 9990.1234.0121 Stey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com