Direct-connected drive mechanism for vertical cycle garage and vertical cycle garage

A technology of vertical circulation and transmission mechanism, which is applied in the direction of buildings, building types, and buildings where cars are parked, and can solve problems such as low transmission efficiency, easy rusting of chains, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

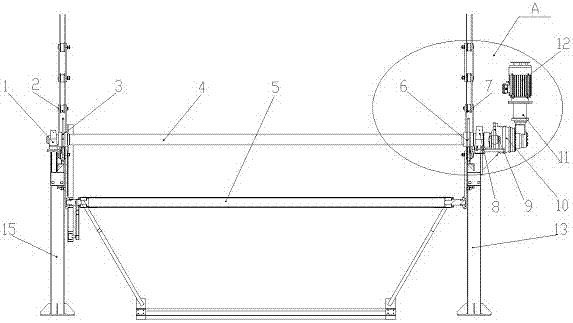

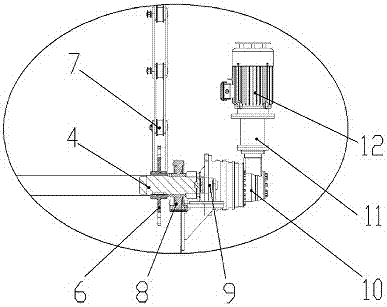

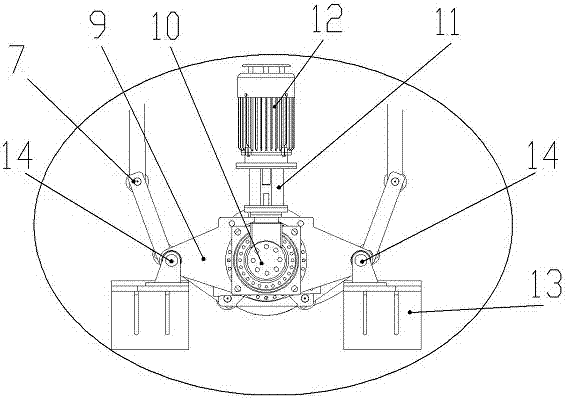

[0020] as attached figure 1 with Figure 4 As shown, the direct-coupled transmission mechanism for the vertical cycle garage of the present invention includes a rear bearing seat (1), a rear lifting chain (2), a rear sheave (3), a transmission shaft (4), and a vehicle-carrying plate device (5 ), front sheave (6), front lifting chain (7), front bearing seat (8), torque arm (9), reducer (10), coupling (11), drive motor (12), front frame (13), bearing pin (14) and rear frame (15).

[0021] The reducer (10) is fixed on the front frame (13) through the torque arm (9) and the pin shaft (14). The reducer (10) is a planetary gear reducer with a large transmission speed ratio and high transmission efficiency. Advantages, the output end is connected to the input end of the drive shaft (4) through a spline, the front sheave (6) and the rear sheave (3) rotate synchronously with the drive shaft (4) through a flat key, and the front sheave (6) and the drive shaft (4) rotate synchronously....

Embodiment 2

[0024] as attached figure 1 with Figure 4 As shown, the vertical cycle garage of the present invention includes a front frame (13) and a rear frame (15) of the garage, a direct-coupled transmission mechanism for the vertical cycle garage, and several car-loading plate devices (5) for carrying cars. , characterized in that: the transmission shaft (4) in the direct-coupled transmission mechanism for the vertical cycle garage is set in the middle of the front frame (13) and the rear frame (15) of the garage, and the drive motor (12), coupling (11) . The speed reducer (10) is arranged outside the front frame (13) of the garage, and the vehicle-carrying plate devices (5) are respectively arranged on both sides of the middle part of the front frame (13) and the rear frame (15) of the garage. The front lifting chain ( 7) Installed in the chain guide of the front frame (13), and the rear lifting chain (2) is installed in the chain guide of the rear frame (15). The chain guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com