Memory module and manufacturing method thereof

A manufacturing method and memory technology, applied in static memory, instruments, etc., can solve the problems of complex overall structure, increased material cost, and inability to improve the penetration rate, and achieve the effect of enhancing visual effects and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in more detail below with reference to figures and reference numerals, so that those skilled in the art can implement them after studying this specification.

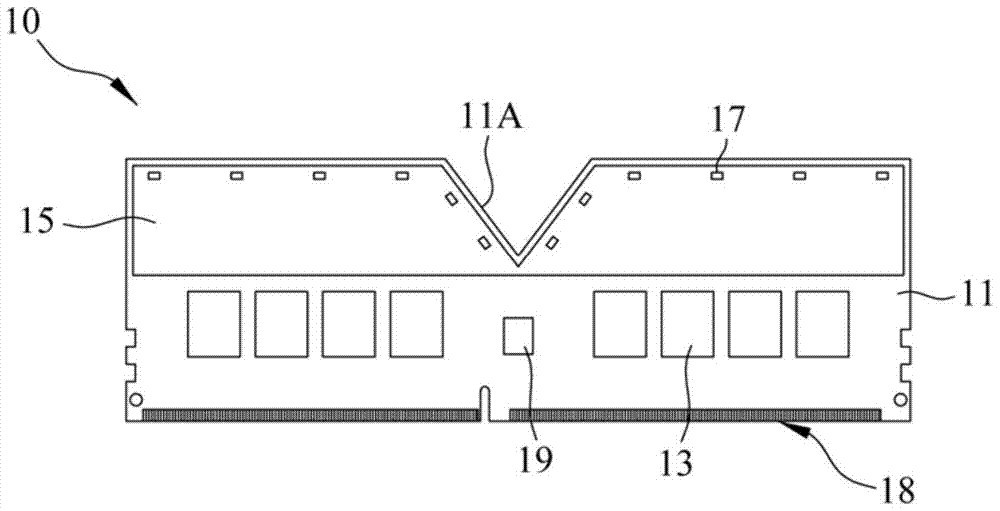

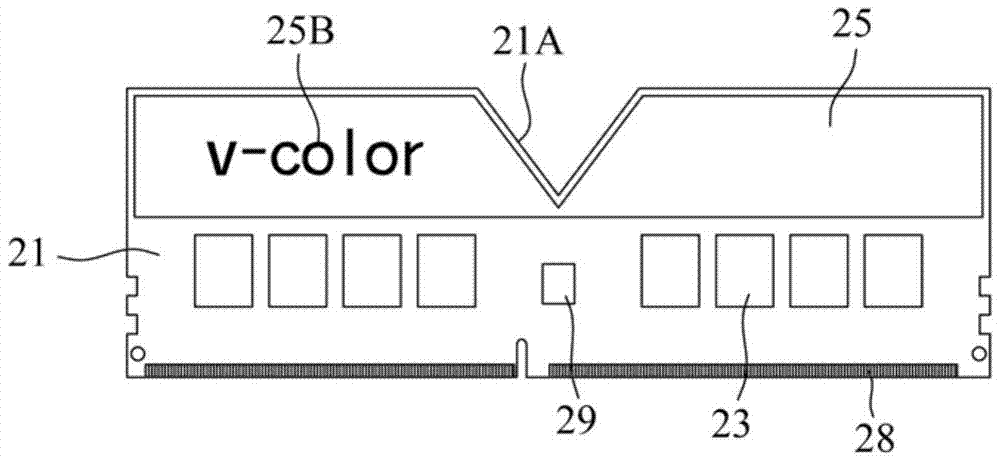

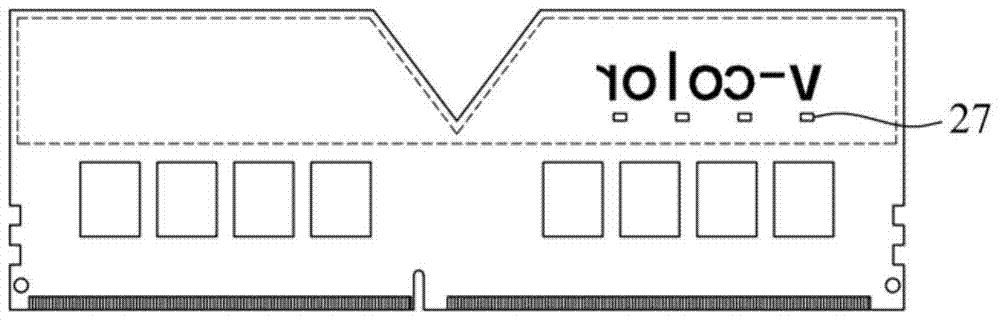

[0040] refer to figure 1 , a schematic diagram of the memory module according to the first embodiment of the present invention. Such as figure 1 As shown, the memory module 10 of the first embodiment of the present invention mainly includes a substrate 11, at least one memory 13, a light-shielding film 15, and at least one light-emitting diode 17, wherein the substrate 11 has light transmission and electrical insulation and includes electrical circuits (not shown in the figure), the light-shielding film 15 is made of copper foil and is opaque, and is arranged on the substrate 11 and is close to the upper edge of the substrate 11, and the memory memory 13 and the light-emitting diode 17 are arranged on the substrate 11 And connected to the electrical cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com