Soft lens clamping instrument and installation structure of soft lens clamping instrument on soft lens surgery assisting robot

A gripper and robot technology, applied in the field of medical devices, can solve the problems of low precision, inconvenient fixation, soft mirror shaking, etc., and achieve the effect of improving versatility and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

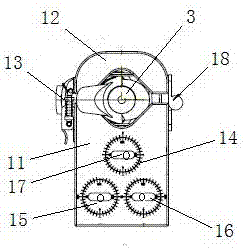

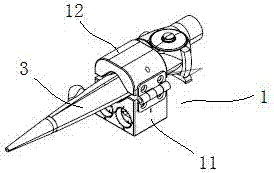

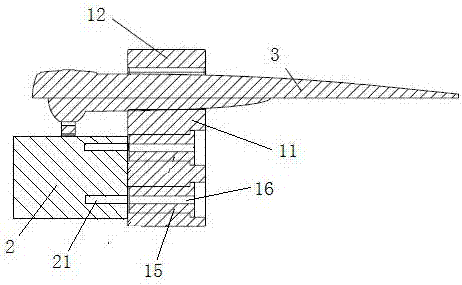

[0022] As shown in the figure, the flexible mirror holder 1 of this embodiment is installed on the soft mirror surgery auxiliary robot for clamping and fixing the flexible mirror 3 . Wherein the flexible mirror surgery auxiliary robot is provided with a flexible mirror holder fixing plate 2, and the flexible mirror holder fixing plate 2 is provided with an installation screw hole 21 parallel to the axial direction of the flexible mirror 3. In order to improve the strength of the support for the body 11, there are at least three mounting screw holes 21 (the same as the number of hollow bolts 15, the number of hollow bolts 15 and the number of mounting screw holes 21 in this embodiment are three), and they are polygonal distribution; of course, the number of mounting screw holes 21 can also be more than the number of hollow bolts 15, and different mounting screw holes 21 can be used to cooperate with the adjusting bolts on the body 11 to fix the body 11 according to needs, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com