Hollow fiber nanofiltration membrane subassembly

A nanofiltration membrane and fiber technology, applied in the field of hollow fiber nanofiltration membrane modules, can solve problems such as increasing the economic cost of the operating system, complex device and system design, and reducing operating efficiency, so as to improve membrane separation efficiency and reduce system operating costs , the effect of reducing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail through the following examples in conjunction with the accompanying drawings. It should be noted that the specific examples herein are only used to understand the present invention, and are not intended to limit the present invention.

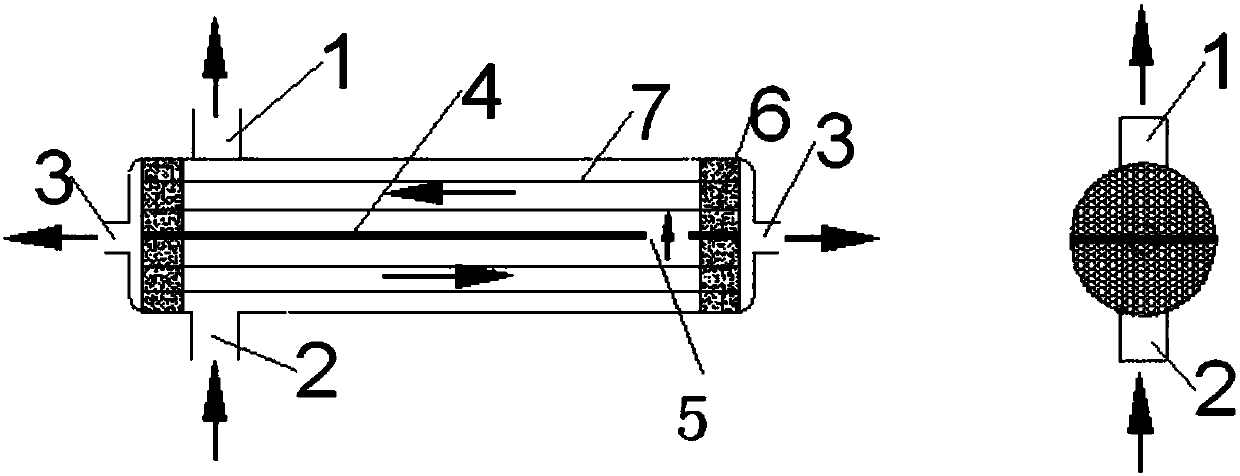

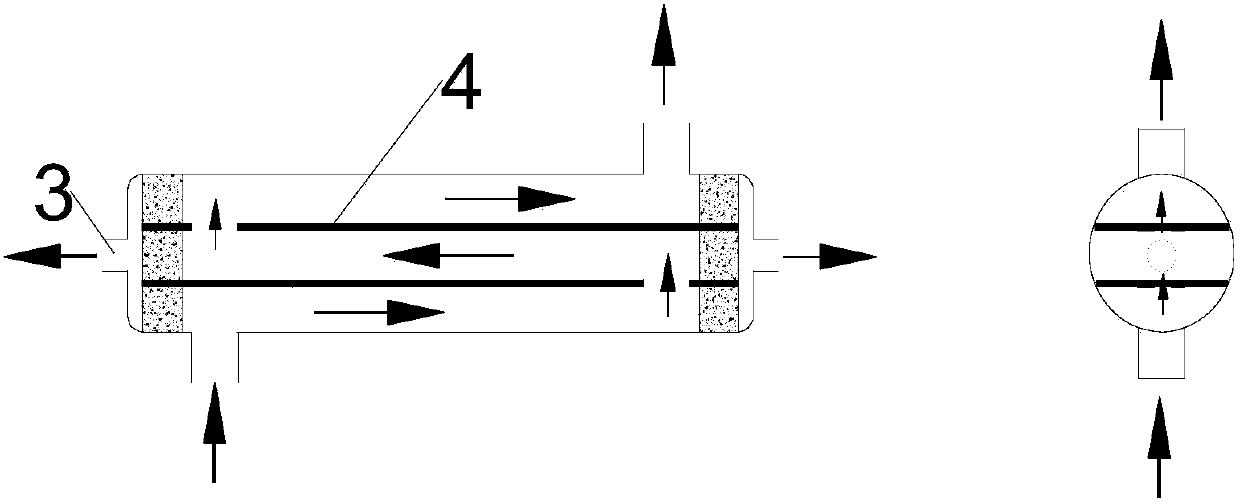

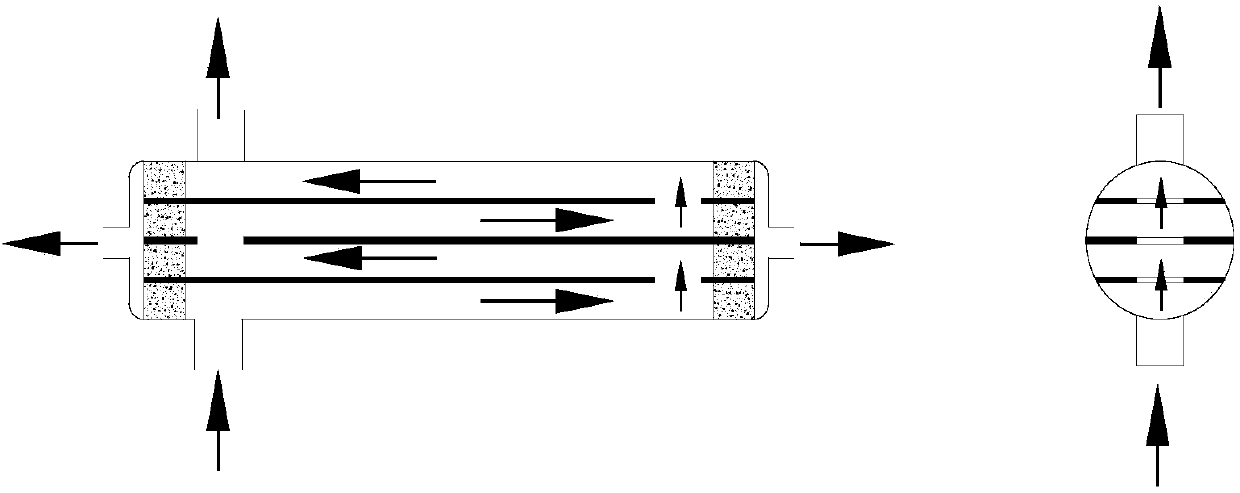

[0029] Figure 1-9 It shows a hollow fiber nanofiltration membrane module, including a membrane housing and a membrane filament unit and a deflector arranged in the membrane housing; the hollow fiber nanofiltration membrane module includes a filter set in the gas-liquid channel The membrane filament unit 7, the deflector 4 used to separate the gas-liquid passage, and the resin-cast fixed layer 6 arranged at both ends of the membrane shell to fix the membrane filament unit and the deflector; The guide plate is provided with a guide hole 5 for gas and liquid to pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com