Automobile clutch damping disk forming lower die

A clutch and automobile technology, applied in forming tools, vehicle parts, metal processing equipment, etc., can solve the problems of troublesome debugging of molds, low work efficiency, and high requirements for depth accuracy, so as to shorten the disassembly and assembly time, save labor costs, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited.

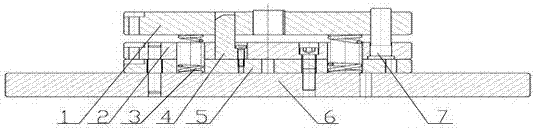

[0013] figure 1 The structure diagram of the present invention is shown, a lower mold for forming an automobile clutch damping disc, including: a lower pre-pressing plate 1, a punch fixing plate 2, a spring 3, a forming punch 4, a lower backing plate 5, and a lower mold seat 6 , inner guide column 7, the forming punch 4 is fixed on the punch fixing plate 2 and fixed on the lower backing plate 5 through a hanging table, the spring 3 is arranged on the punch fixing plate 2 and In the through hole between the lower backing plates 5, the punch fixing plate 2 is locked with the lower backing plate 5 and the lower mold base 6, and the inner guide column 7 is fixed on the punch. The relative position of the lower pre-loading plate 1 is limited on the plate 2, and the lower pre-loading plate 1 can move up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com