Fast-assembling heating pipe

A heating tube and quick-installation technology, applied in the shape of heating elements, ohmic resistance heating parts, etc., can solve the problems of excessive disassembly and assembly time, short circuit of terminals, and burnout of heating tubes, etc., to improve safety performance and cost. Inexpensive and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

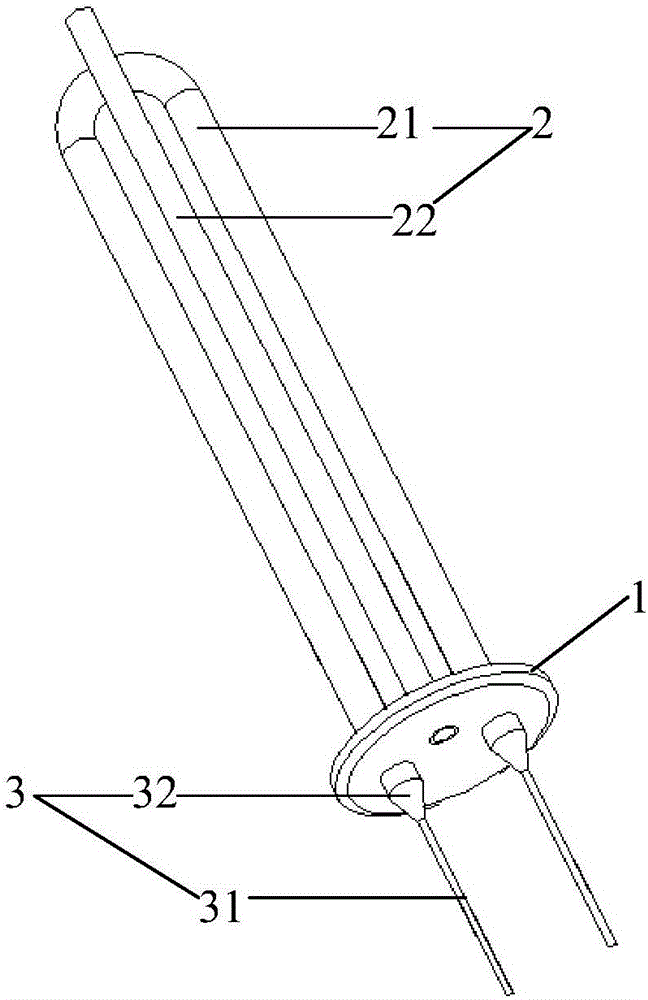

[0024] see figure 1 As shown, it is a schematic structural view of the quick-installation heating tube of the present invention without a standard ferrule set.

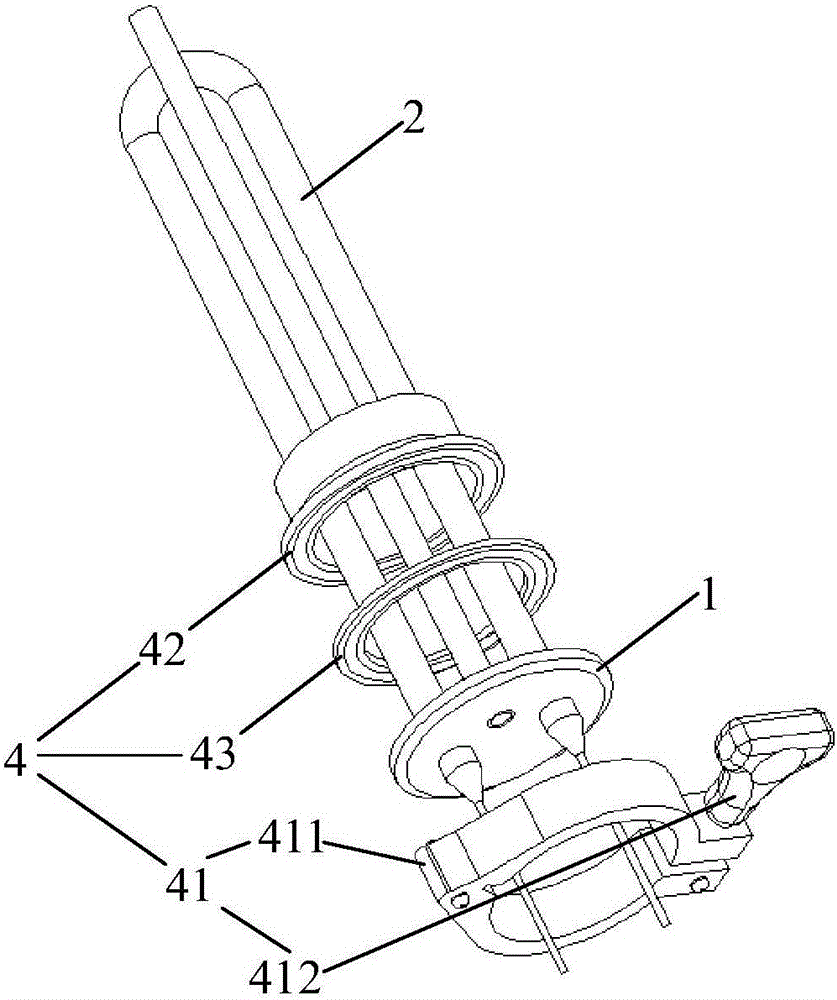

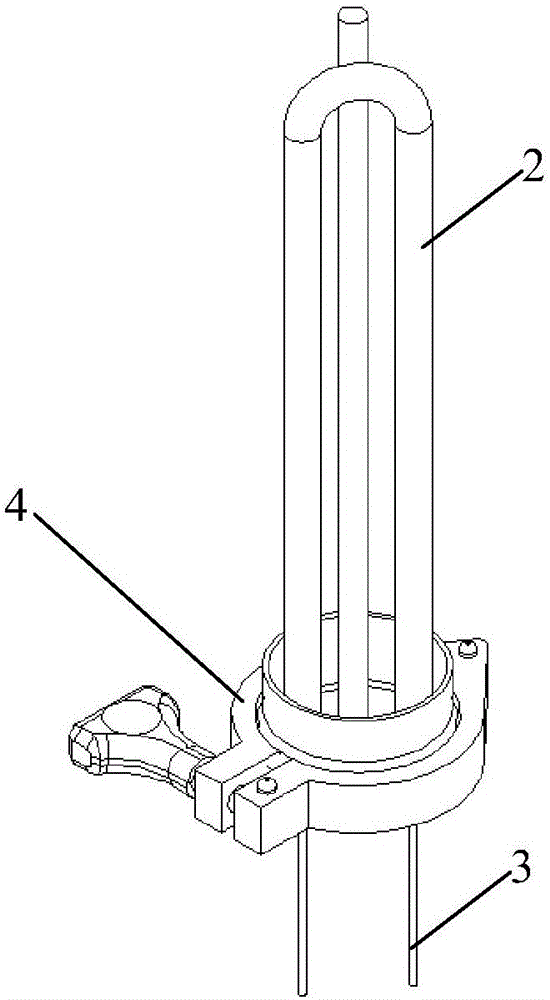

[0025] In one embodiment, as figure 1 , 2 As shown in . Group 2, the heating tube group 2 includes an electric heating tube 21 and an over-temperature protection tube 22 , and both the electric heating tube 21 and the over-temperature protection tube 22 are electrically connected to the wiring 3 . The quick-fit heating tube also includes a standard ferrule set 4, the standard ferrule set 4 includes a ferrule 41 and a socket 42, and the socket 42 is sleeved on the base 1 to set the heating tube set 2 On one side, the ferrule 41 is sleeved and clamped and fixed outside the base 1 and the sleeve 42 . Such as figure 2 As shown, the standard ferrule set 4 may further include a seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com