Coaxial monitoring method and device for laser selective melting process

A laser selective melting and processing technology, applied in measurement devices, optical devices, additive processing, etc., can solve the problem of inability to fine molten pool, low resolution and detection rate, disturbing metal microstructure or macro mechanical properties, etc. problem, to achieve high local resolution and fast scan rate, good detection and analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

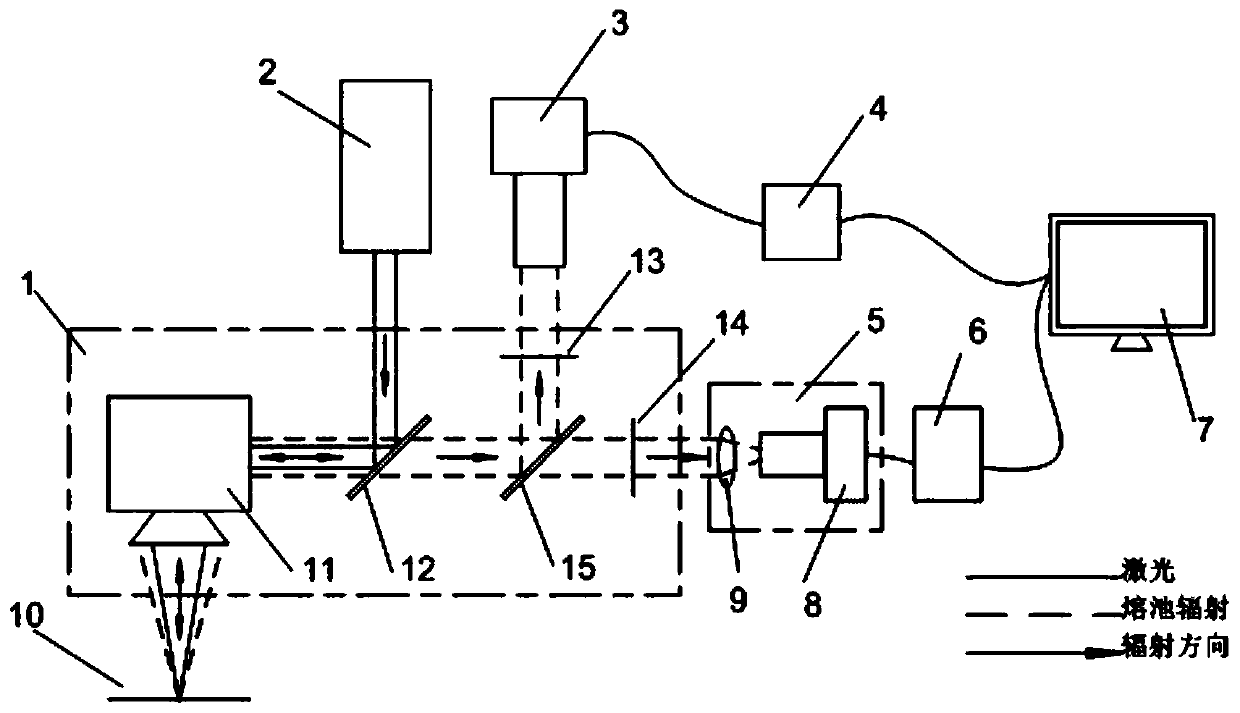

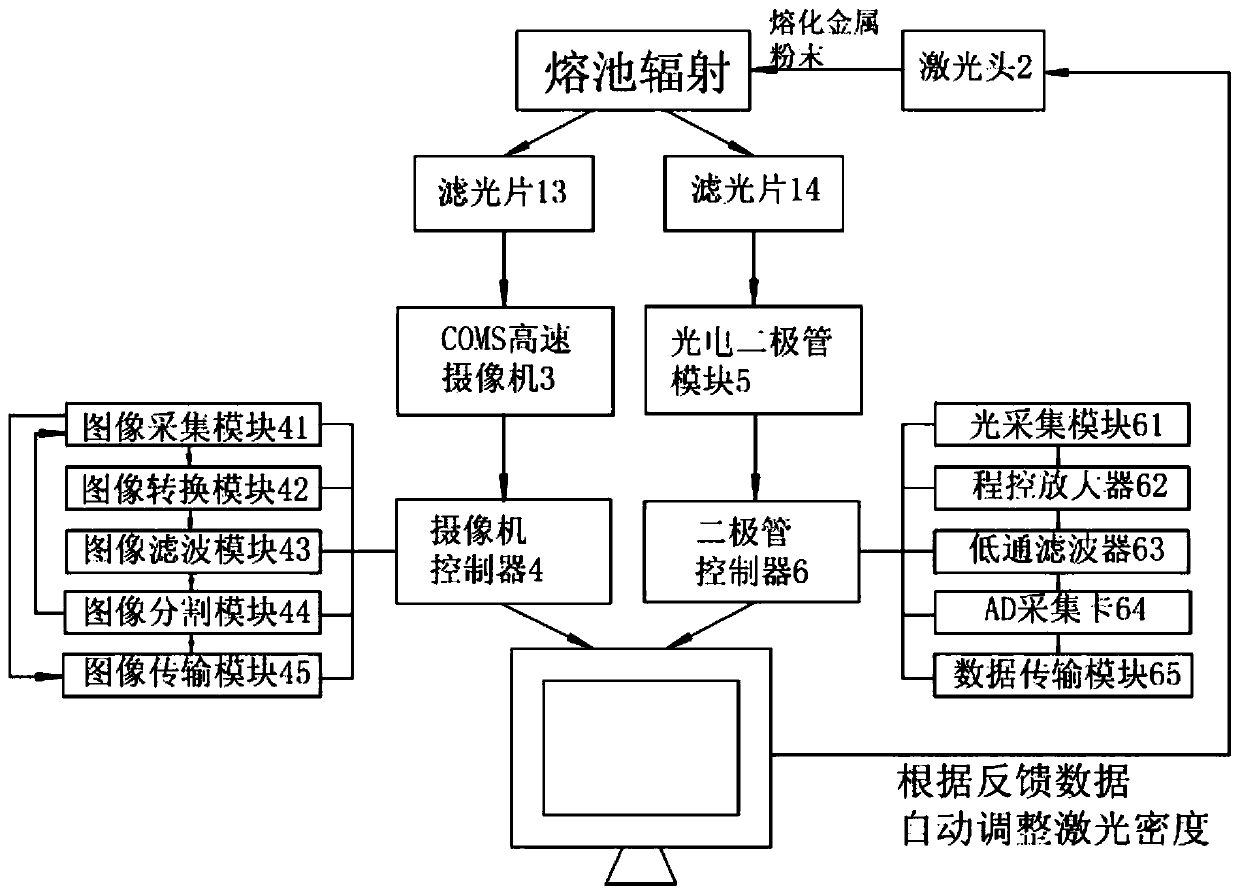

[0043] Such as figure 1 , 2 shown. The invention discloses a coaxial monitoring device for selective laser melting process, comprising an optical path module 1, a photodiode module 5, a diode controller 6, a laser head 2, a COMS high-speed camera 3, a camera controller 4, and a computer 7;

[0044] The photodiode module 5 includes a focusing lens 9 and a photodiode 8; the photodiode 8 is connected to the computer 7 by a diode controller 6; the COMS high-speed camera 3 is connected to the computer 7 by a camera controller 4;

[0045] The optical path module 1 includes a scanning vibrating mirror 11, a half-mirror 12, a first filter 13, a second filter 14, a beam splitter 15; the scanning vibrating mirror 11, a half-mirror 12 , beam splitter 15, the second optical filter 14, focusing lens 9, photodiode 8 are connected in the optical path successively; COMS high-speed camera 3 is connected with beam splitter 15 optical paths by the first optical filter 13; Laser head 2 and semi-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com