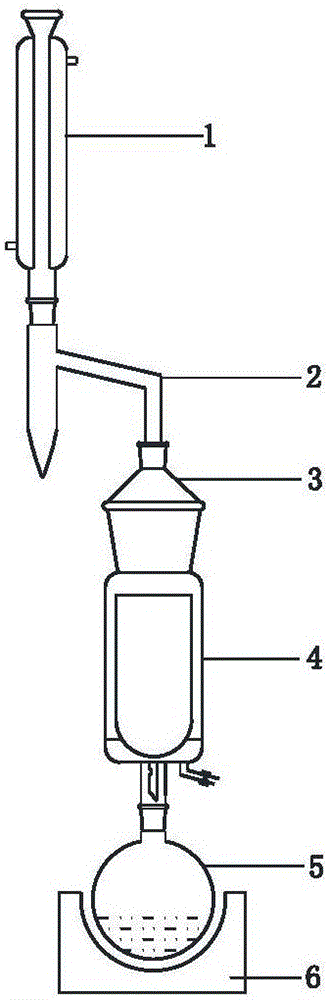

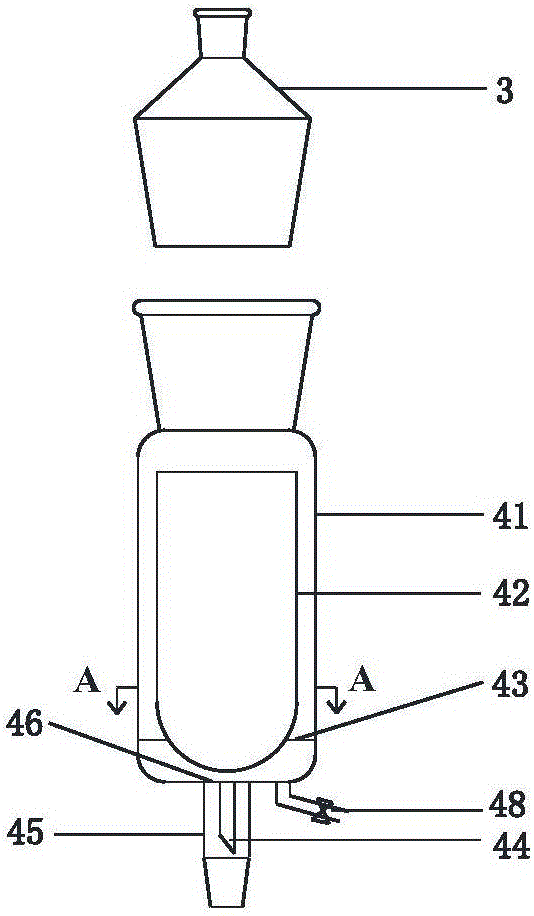

Reflux type oil sand oil content and moisture synchronous determination system and determination method

A measuring system and technology for oil content, applied in the field of synchronous measuring system for oil content and water content of refluxing oil sands, can solve problems such as large sampling error, and achieve the goal of reducing fine powder correction, saving dosage, and promoting liquid-solid mass transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

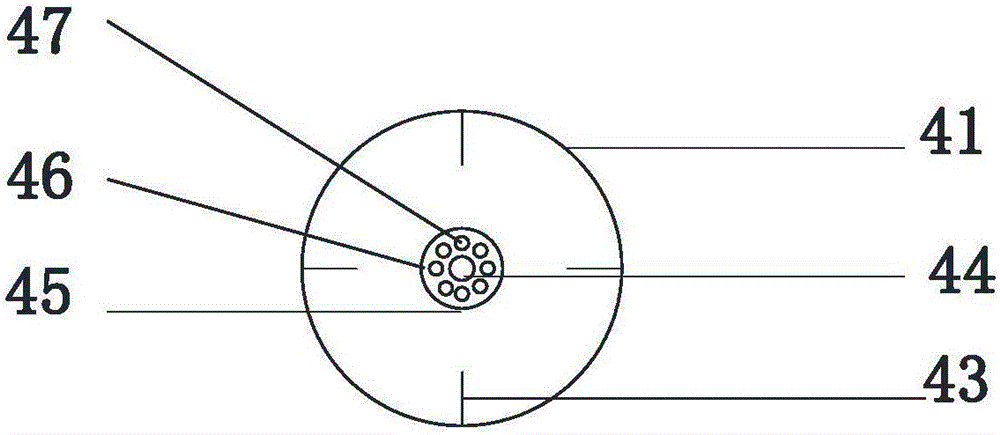

Method used

Image

Examples

Embodiment 1

[0063] oil sands 1 As the sample to be tested, use the above-mentioned device and method to measure its oil, water and solid residue content, dry the residue of the sample to be tested at 145°C after extraction, volatilize the xylene and weigh the sample until the sample has a constant weight. Measure the amount of solid residue, distill out the solvent in the flask, weigh the amount of oil sand bitumen after constant weight, and calculate the contents of oil, water and solid residue respectively. The measurement results are listed in the table below.

[0064] Oil sand sample S 1 The oil content measurement results are shown in Table 1:

[0065] Table 1

[0066] Measurement times

1

2

3

4

average

standard deviation

oil content

30.11

29.06

30.09

30.23

29.8725

0.5452

[0067] Oil sand sample S 1 The moisture content measurement result is shown in Table 2:

[0068] Table 2

[0069] Measurement t...

Embodiment 2

[0075] oil sands 2 As the sample to be tested, use the device and method of the present invention to measure its oil, water and solid residue content, dry the residue of the sample to be tested at 145 ° C after the extraction is completed, and volatilize the xylene until the sample has a constant weight. Weigh the amount of solid residue, distill out the solvent in the flask, weigh the amount of oil sand pitch after constant weight, and calculate the contents of oil, water and solid residue respectively. The measurement results are listed in the table below.

[0076] Oil sand sample S 2 The oil content measurement results are shown in Table 4:

[0077] Table 4

[0078] Measurement times

1

2

3

4

average

standard deviation

oil content

13.74

14.03

14.83

14.17

14.1925

0.4612

[0079] Oil sand sample S 2 The oil content measurement results are shown in Table 5:

[0080] table 5

[0081] Measuremen...

Embodiment 3

[0086] oil sands 2 As the sample to be tested, use the device and method of the present invention to measure its oil, water and solid residue content, dry the residue of the sample to be tested at 145 ° C after the extraction is completed, and volatilize the xylene until the sample has a constant weight. Weigh the amount of solid residue, distill out the solvent in the flask, weigh the amount of oil sand bitumen after constant weight, and calculate the contents of oil, water and solid residue respectively. The measurement results are listed in the table below.

[0087] Oil sand sample S 2 The oil content measurement results are shown in Table 7:

[0088] Table 7

[0089] Measurement times

1

2

3

4

average

standard deviation

oil content

22.71

21.56

21.83

22.17

22.0675

0.4957

[0090] Oil sand sample S 2 The oil content measurement results are shown in Table 8:

[0091] Table 8

[0092] Measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com