Sample plate conveying device

A conveying device and prototype technology, which is applied in the direction of transportation, packaging, and slideways, etc., can solve the problems of increasing the work intensity, difficulty and working time of workers, potential safety hazards of workers, and different states of horizontal and vertical, so as to avoid re-handling Adjustment, protection of personal safety, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will further explain the template conveying device of the present invention in conjunction with the accompanying drawings and specific embodiments, but the explanation does not constitute an improper limitation of the technical solution of the present invention.

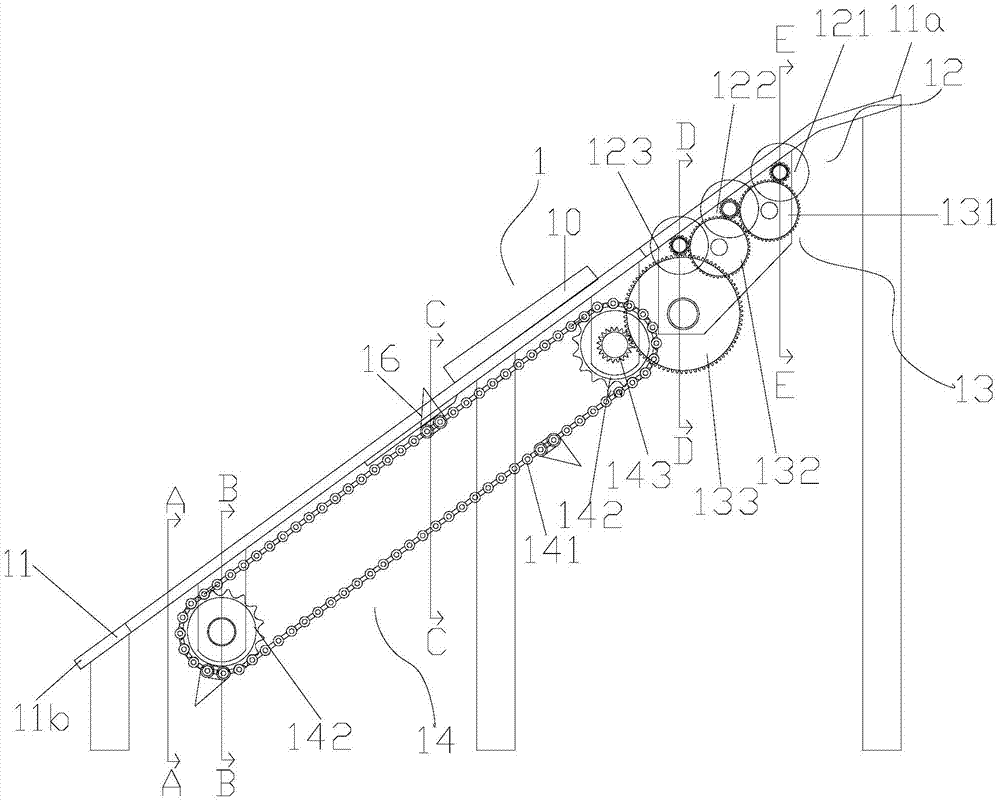

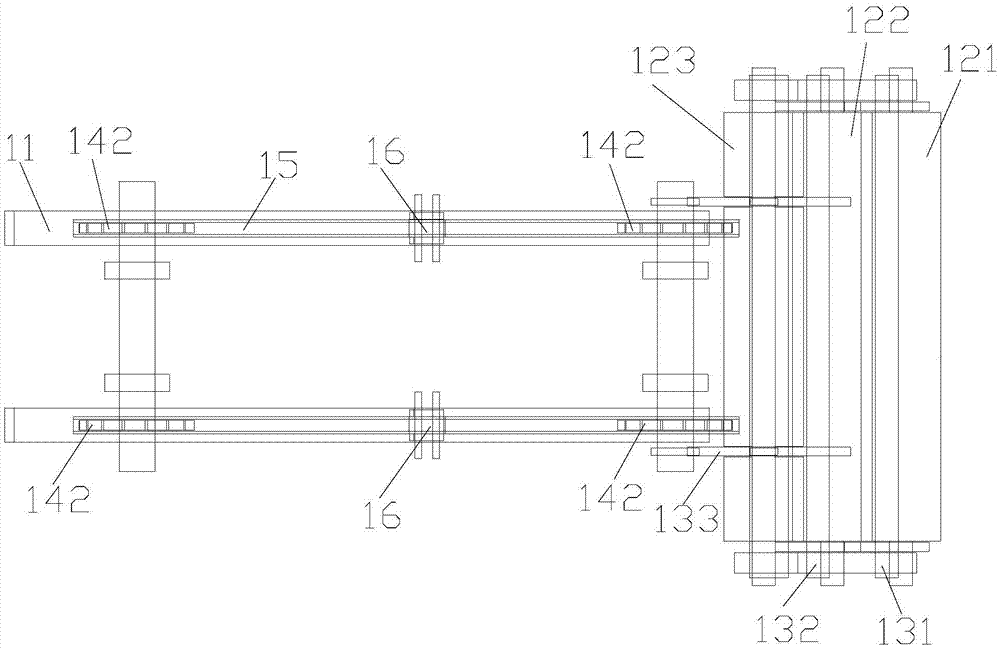

[0034] figure 1 and figure 2 The structure of the template conveying device according to the present invention in an embodiment is shown from different viewing angles.

[0035] image 3 The structure of the tank in the template conveying device according to the present invention is shown.

[0036] Figure 4 It shows the structure of the chain, chain gear and stopper in the template conveying device of the present invention.

[0037] Figure 5 It shows the structure of the chain, the stopper and the groove in the sample conveying device of the present invention.

[0038] Figure 6 and Figure 7 The structures of the passive roller and the transmission gear in the template conveying device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com