Process and system for returning pulverized coal

A technology of pulverized coal and process, applied in the field of pulverized coal return process and system, can solve the problem that pulverized coal cannot be transferred to each other, and achieve the effect of reasonable process design concept, low manufacturing cost, and high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

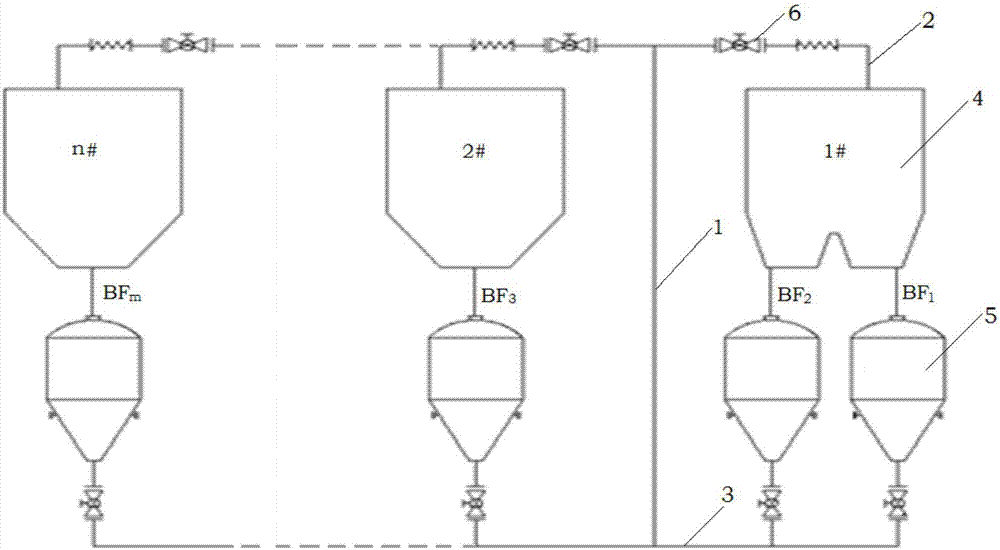

[0024] Such as figure 1 As shown: a pulverized coal return process in this embodiment uses the pulverized coal return pipeline to realize mutual transportation of pulverized coal between coal injection systems, and the pulverized coal return process includes the following steps:

[0025] 1). Judging the coal injection system with surplus pulverized coal and the coal injection system with insufficient pulverized coal;

[0026] 2). Draw out the surplus pulverized coal in the pulverized coal surplus coal injection system;

[0027] 3). Utilize the coal injection system with surplus pulverized coal to inject the surplus pulverized coal;

[0028] 4). The surplus pulverized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com