Unfixed yarn and pressure drying method thereof

A pressure and yarn technology, applied in the field of unfixed yarn and its pressure drying, can solve the problems of uneven dyeing, migration, color spots, etc., and achieve the effect of ensuring production quality, excellent quality, and no migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

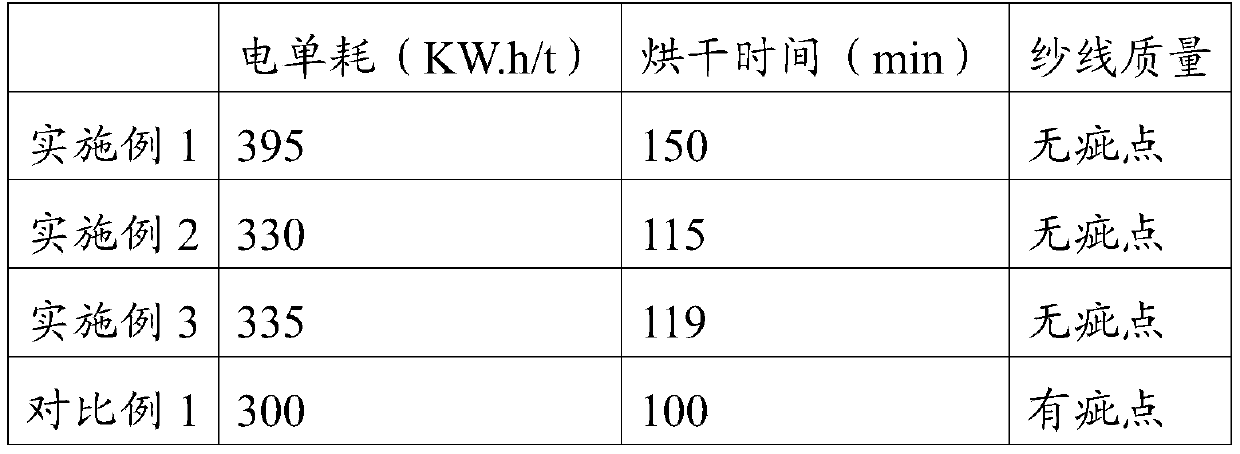

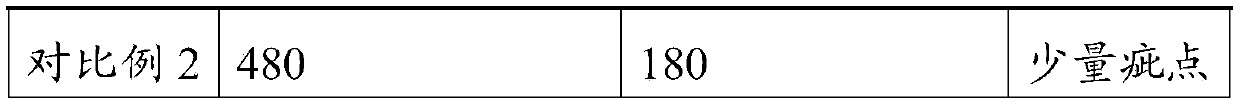

Examples

Embodiment 1

[0026] This embodiment is a pressure drying method for unfixed yarns. The unfixed yarns are yarns obtained directly without fixing or other post-processing after the conventional dyeing process, using a THIES pressure dryer Pressure drying includes the following steps:

[0027] (1) Obtain the unfixed yarn and squeeze water. The process of squeezing the water is as follows: at a temperature of 90° C. and a pressure of 4.7 Bar, the unfixed yarn is squeezed for 10 minutes; In this process, the fan power is below 100%, the temperature difference at T1 is 0, and the temperature difference at T2 is below 40°C.

[0028] (2) Pre-drying the yarn after squeezing water. The pre-drying process is: pre-drying for 30 minutes at a temperature of 90°C and a pressure of 4.7 Bar; in this process, the fan power is 100 % Or less, T1 temperature difference is 0, T2 temperature difference is 40°C or less.

[0029] (3) Dry the pre-dried yarn. The drying process is: drying for 70 minutes at a temperature ...

Embodiment 2

[0033] This embodiment is a pressure drying method for unfixed yarns. The unfixed yarns are yarns that have not undergone fixation treatment after a conventional dyeing process, and are pressure-dried using a THIES pressure dryer, including The following steps:

[0034] (1) Obtain the unfixed yarn and squeeze water. The process of squeezing the water is as follows: at a temperature of 80° C. and a pressure of 4.7 Bar, the unfixed yarn is squeezed for 10 minutes; In this process, the fan power is below 100%, the temperature difference at T1 is 0, and the temperature difference at T2 is below 40°C.

[0035] (2) Pre-drying the yarn after squeezing water. The pre-drying process is: pre-drying for 40 minutes at a temperature of 95°C and a pressure of 4.7 Bar; in this process, the fan power is 100 % Or less, T1 temperature difference is 0, T2 temperature difference is 40°C or less.

[0036] (3) Dry the pre-dried yarn. The drying process is: at a temperature of 100°C and a pressure of 4.7...

Embodiment 3

[0040] This embodiment is a pressure drying method for unfixed yarns. The unfixed yarns are yarns that have not undergone fixation treatment after a conventional dyeing process, and are pressure-dried using a THIES pressure dryer, including The following steps:

[0041] (1) Obtain unfixed yarns and squeeze water. The process of squeezing water is as follows: at a temperature of 60°C and a pressure of 4.7 Bar, the unfixed yarns are squeezed for 20 minutes; In this process, the fan power is below 100%, the temperature difference at T1 is 0, and the temperature difference at T2 is below 40°C.

[0042] (2) Pre-dry the yarn after squeezing water. The process of pre-drying is: pre-drying for 40 minutes at a temperature of 85°C and a pressure of 4.7 Bar; in this process, the fan power is 100 % Or less, T1 temperature difference is 0, T2 temperature difference is 40°C or less.

[0043] (3) Dry the pre-dried yarn. The drying process is: drying for 60 minutes at a temperature of 105°C and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com