Steel belt reciprocating knife cutting high-efficiency slag filter cake dryer

A dryer and steel belt technology, applied in dryers, progressive dryers, drying and other directions, can solve the problems of inconvenient continuous operation, incomplete drying, low efficiency, etc., and achieve high-efficiency heat exchange drying and drying. High efficiency and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with accompanying drawing, the present invention is described in further detail.

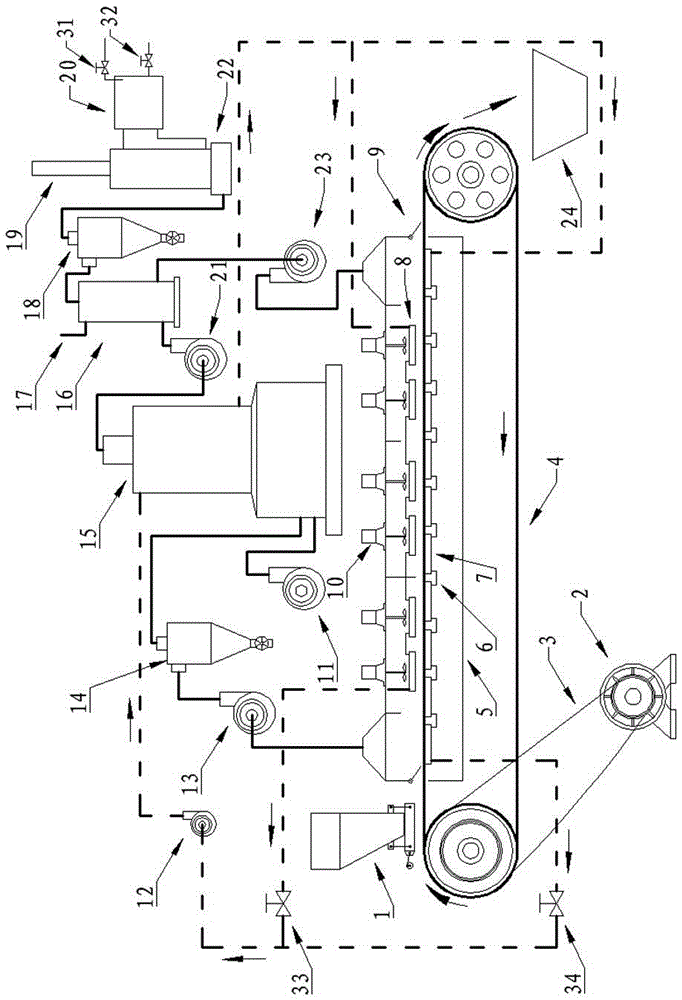

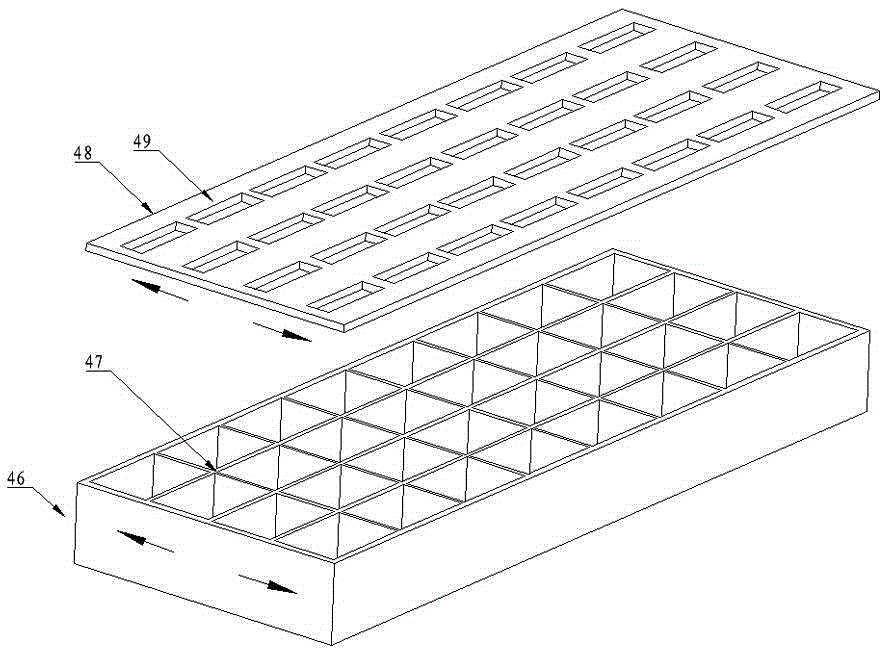

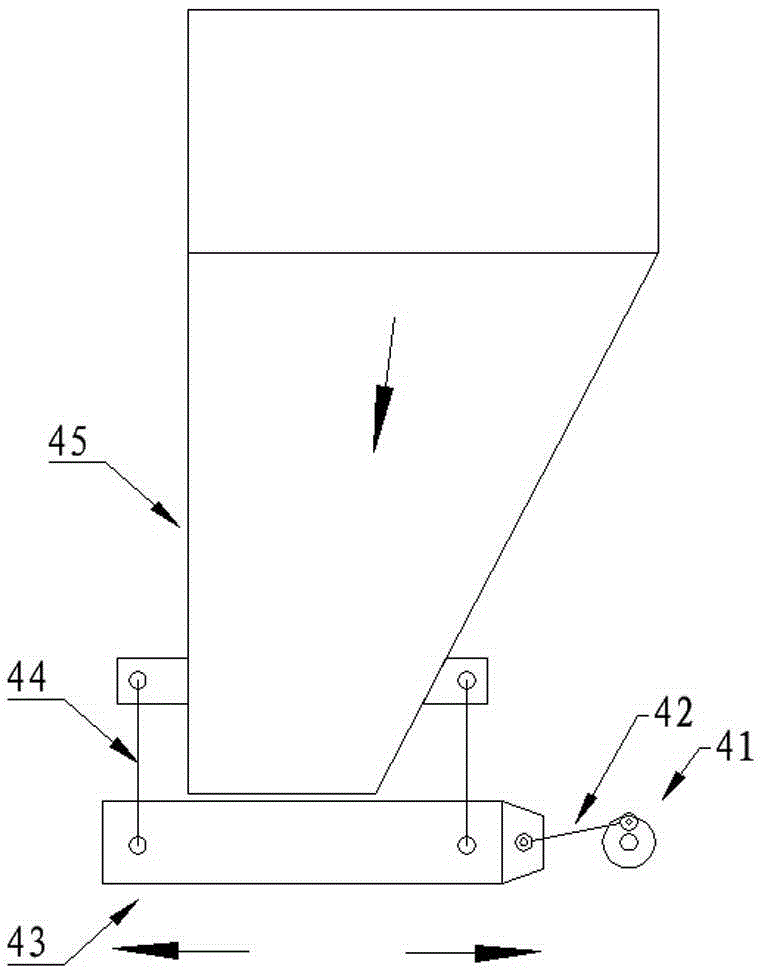

[0034] like figure 1 , figure 2 , image 3 and Figure 4 The shown steel belt type reciprocating knife cutting high-efficiency slag filter cake dryer includes a heat transfer oil furnace 15, a reciprocating knife cutting machine 1, a steel belt 4 and a drying body 5. The inner structure of the drying body 5 is a steel belt 4 The flat plate heating body 7 is arranged, connected in series through the connecting pipe 6 as a support and heat source, and the finned heating body 8 on the steel belt 4 is connected in series through the connecting pipe 6 as a heat source for material surface radiation and air circulation internal circulation, and at the same time, a motor 10 drives a fan to realize the drying of the body 5 Internal air flow penetrating hot air circulation drying; there are movable material doors 9 at both ends of the dryer body 5, which realizes the dynamic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com