Stepless height adjusting type built-in type vibration isolating device

A built-in, height-adjusting technology, applied in the field of vibration isolation devices and built-in vibration isolators, can solve the problems of difficult maintenance and replacement, many types of height-adjusting gaskets, and easy deformation of gaskets, so as to achieve stable and reliable vibration isolation performance. , Broad market application prospects, the effect of convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

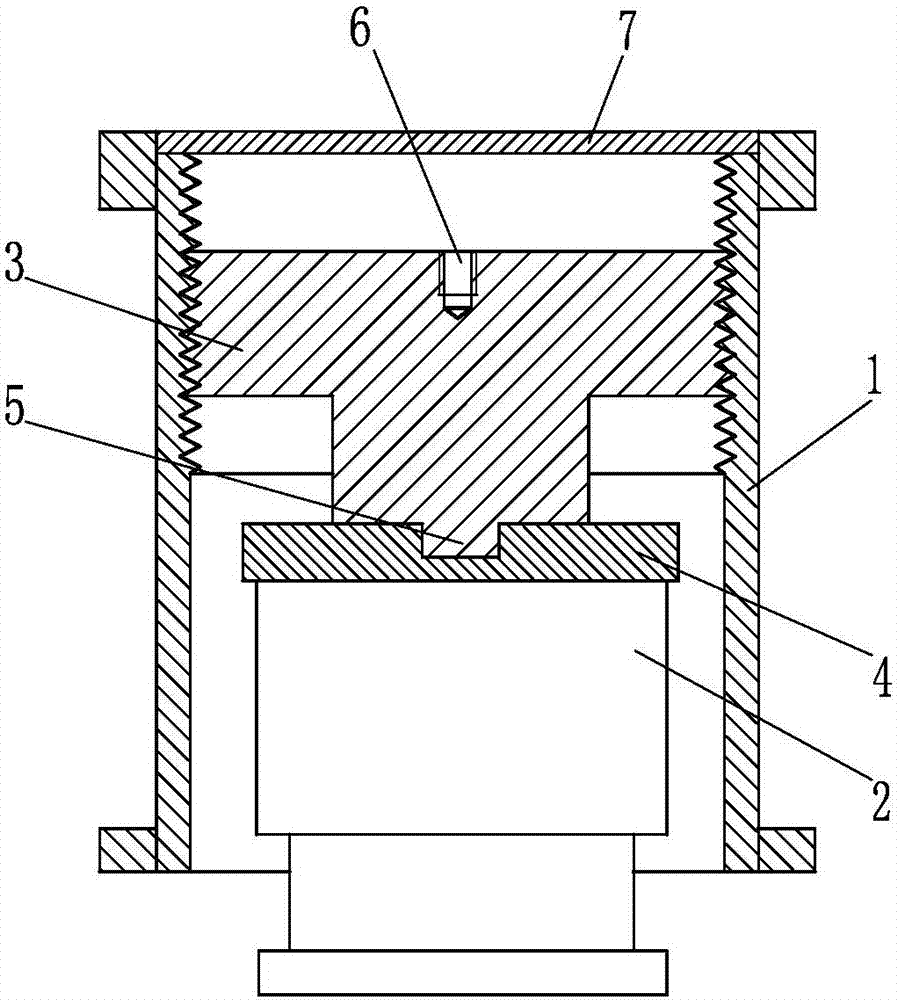

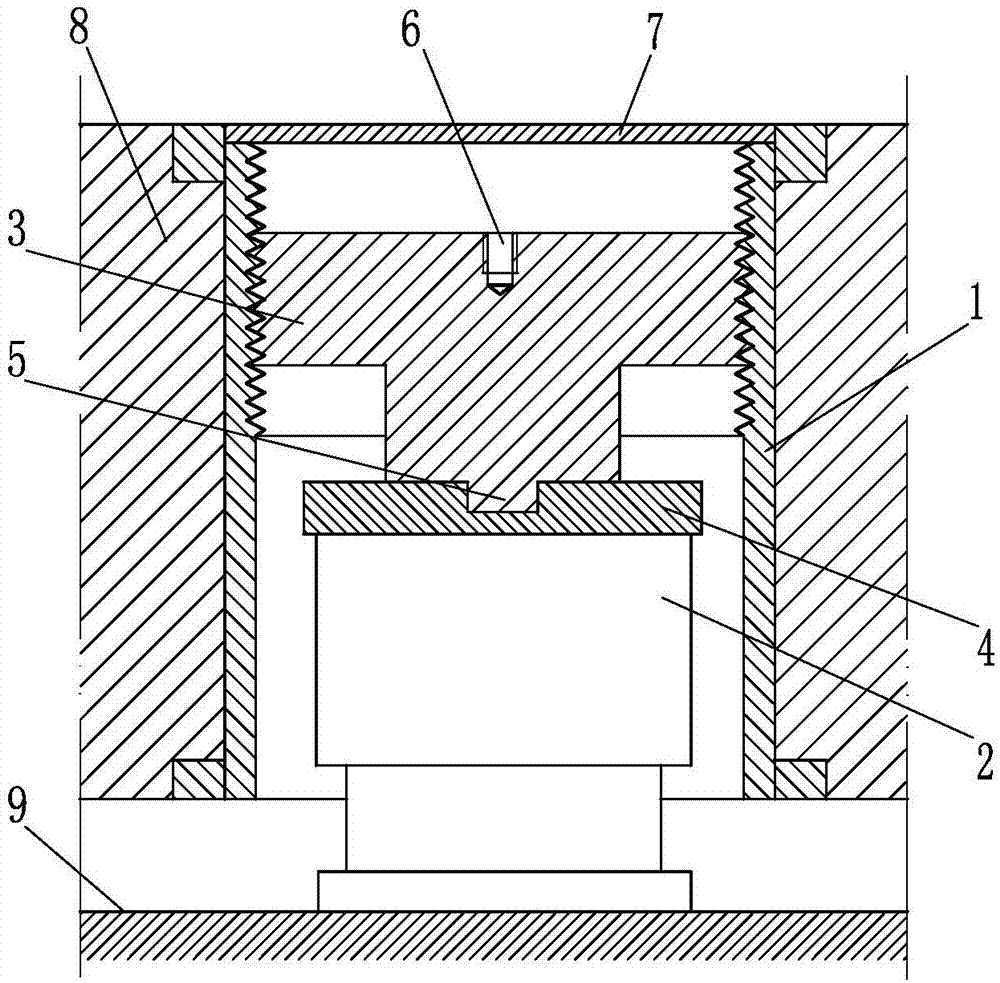

[0035] Such as figure 1The stepless height adjustment type built-in vibration isolation device shown includes a coupling sleeve 1, an elastic vibration isolator 2, and a height adjustment screw 3. The partial inner surface of the coupling sleeve 1 and the local outer surface of the height adjustment screw 3 are The surface is correspondingly provided with threads, and the two are connected by thread fit; the height-adjusting screw 3 is arranged above the elastic vibration isolator 2, and the two are matched by a convex-concave structure. The convex-concave structure includes the top plate 4 of the elastic vibration isolator 2 A groove and a protrusion 5 corresponding to the bottom end of the height-adjusting screw 3 are arranged on the top; in addition, a connecting structure 6 is provided on the top of the height-adjusting screw, and the connecting structure 6 is specifically a threaded hole, and the threaded part of the threaded hole The helical direction is opposite to the ...

Embodiment 2

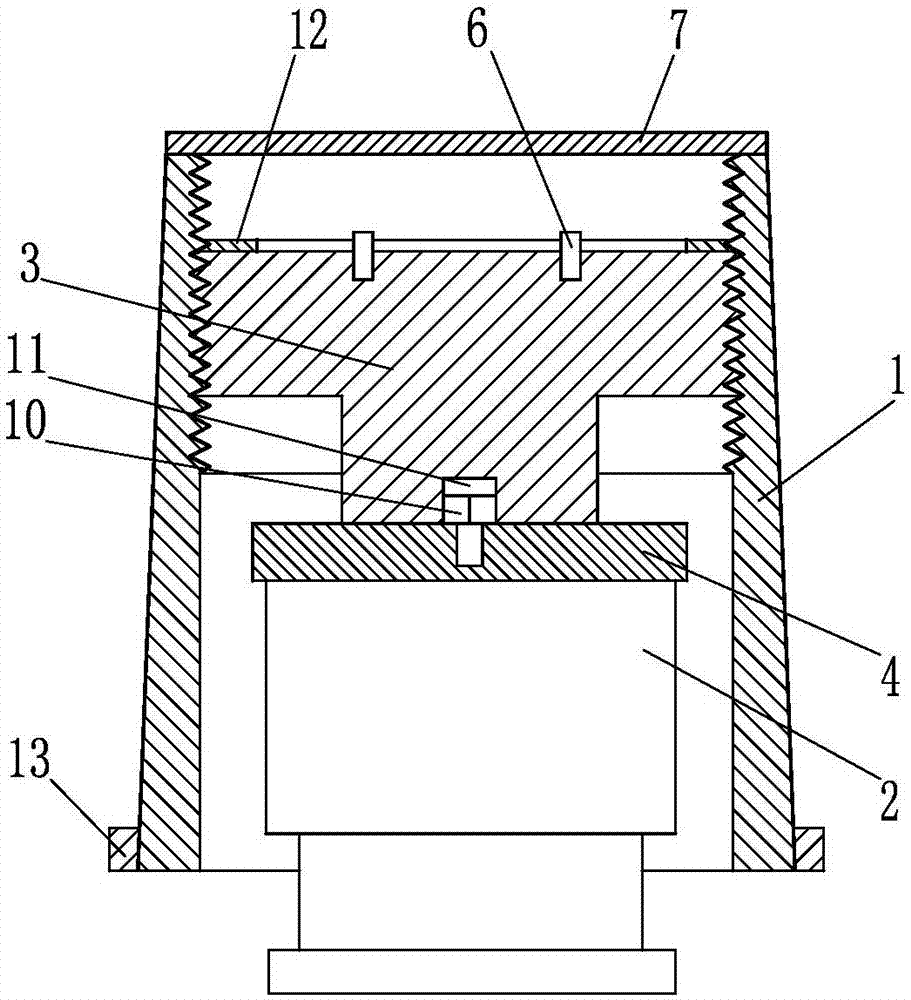

[0041] Such as image 3 and Figure 4 The difference between the stepless height adjustment type built-in vibration isolation device of the present invention and the first embodiment is that the outer surface profile of the vertical center section of the connecting sleeve 1 is a trapezoid with a smaller upper part and a larger lower part, and the bottom of the connecting sleeve 1 Limiting protrusions 13 are provided on the outside of the side; in addition, the height-adjusting screw 3 and the elastic vibration isolator 2 are matched through a convex-concave structure, and the convex-concave structure includes the fastener 10 provided on the top plate 4 of the elastic vibration isolator 2 and the corresponding counterbore 11 provided at the bottom of the height-adjusting screw 3; in addition, the connection structure 6 provided at the top of the height-adjusting screw specifically includes two fixed connecting pins; fourthly, for the consideration of preventing accidental rotat...

Embodiment 3

[0045] Such as Figure 6 The difference between the stepless height adjustment type built-in vibration isolation device of the present invention and the first embodiment is that a bushing 14 is provided between the coupling sleeve 1 and the height adjustment screw 3, and the inner part of the bushing 14 , the outer surfaces are respectively provided with threads, and the connecting sleeve 1, the bushing 14 and the height adjustment screw 3 are connected through threads in turn; in addition, the connection structure 6 provided at the top of the height adjustment screw is specifically a hexagonal counterbore; in addition, the height adjustment The screw 3 and the elastic vibration isolator 2 are matched by a convex-concave structure. The convex-concave structure includes a groove provided at the bottom of the height-adjusting screw, and the top plate 4 of the elastic vibration isolator 2 is embedded in the bottom of the height-adjusting screw. in the groove.

[0046] The applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com