Fabricated bridge construction method based on BIM

A bridge construction and assembly technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as high installation accuracy requirements, backward prefabrication technology, and inability to install prefabricated components, so as to improve accuracy and improve work efficiency and economic value, the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The BIM-based prefabricated bridge construction method includes the following steps:

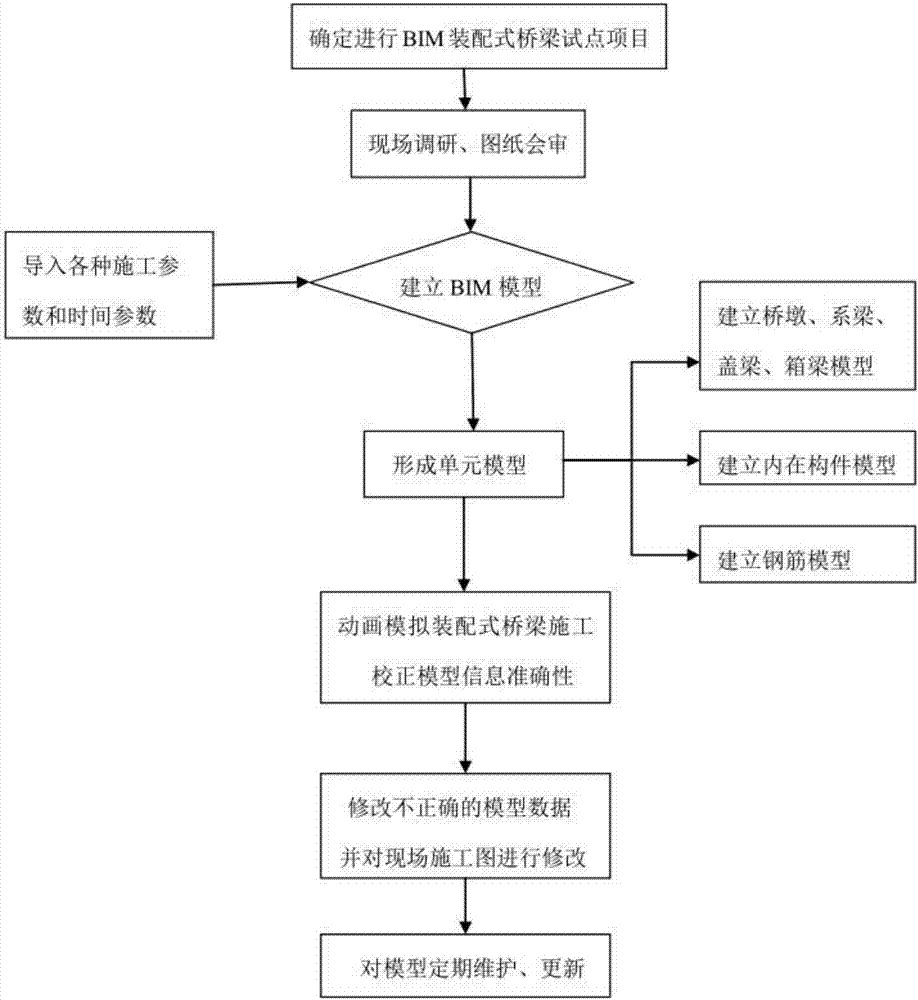

[0020] 1. According to the project design drawings and construction parameters, use the Revit modeling platform to establish the BIM unit models of the piers, tie girders, cover girders, box girders, internal components and steel bars of the prefabricated bridge, and assign time parameters to each unit model, see figure 1 .

[0021] 2. After the modeling of all unit models is completed, simulate the assembly process of the entire prefabricated bridge through 4D animation simulation. During the assembly simulation process, check whether there is any error in the position of the embedded parts when modeling the various parts of the prefabricated bridge, and simulate the assembly Whether there is any situation that cannot be installed during the process, and highlight the position where the BIM unit model has errors or cannot be installed, indicating that there is an error. Finally, revi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com