Open caisson support structure and open caisson construction method

A supporting structure and caisson technology, applied in infrastructure engineering, construction, etc., can solve problems such as waste of reinforced concrete resources, and achieve the effects of stable structure, easy assembly, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

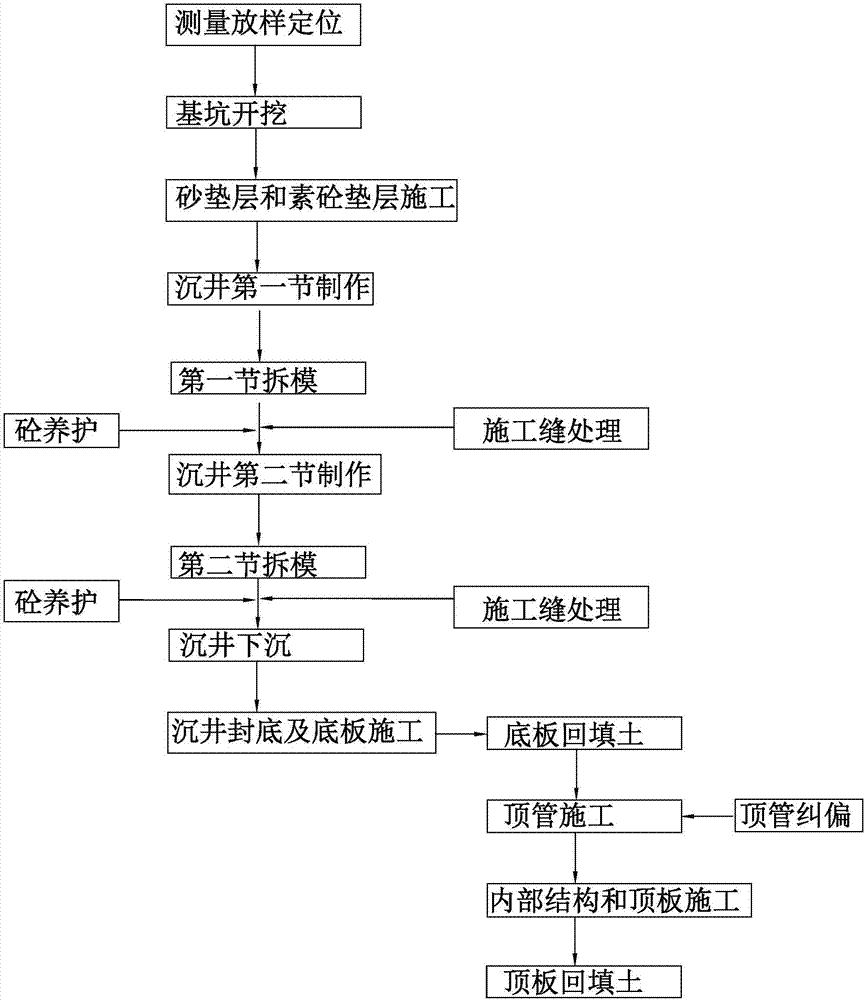

[0041] Embodiment one: a kind of caisson construction method, with reference to figure 1 , including the following workflows: surveying and lofting positioning, excavation of foundation pit, construction of sand cushion and plain concrete cushion, fabrication of caisson first section, first section formwork removal, caisson second section production, second section formwork removal , caisson sinking, caisson bottom sealing and floor construction, floor backfill, pipe jacking construction, internal structure and roof construction, and roof backfill.

[0042] Among them, after the first section of the caisson and the second section of the caisson are removed, concrete maintenance and construction joint treatment are required.

[0043] Include the following steps:

[0044] Step 1: Foundation pit measurement and setting out. According to the geological conditions revealed in the caisson design drawings and engineering geological reports, determine the excavation depth of the cais...

Embodiment 2

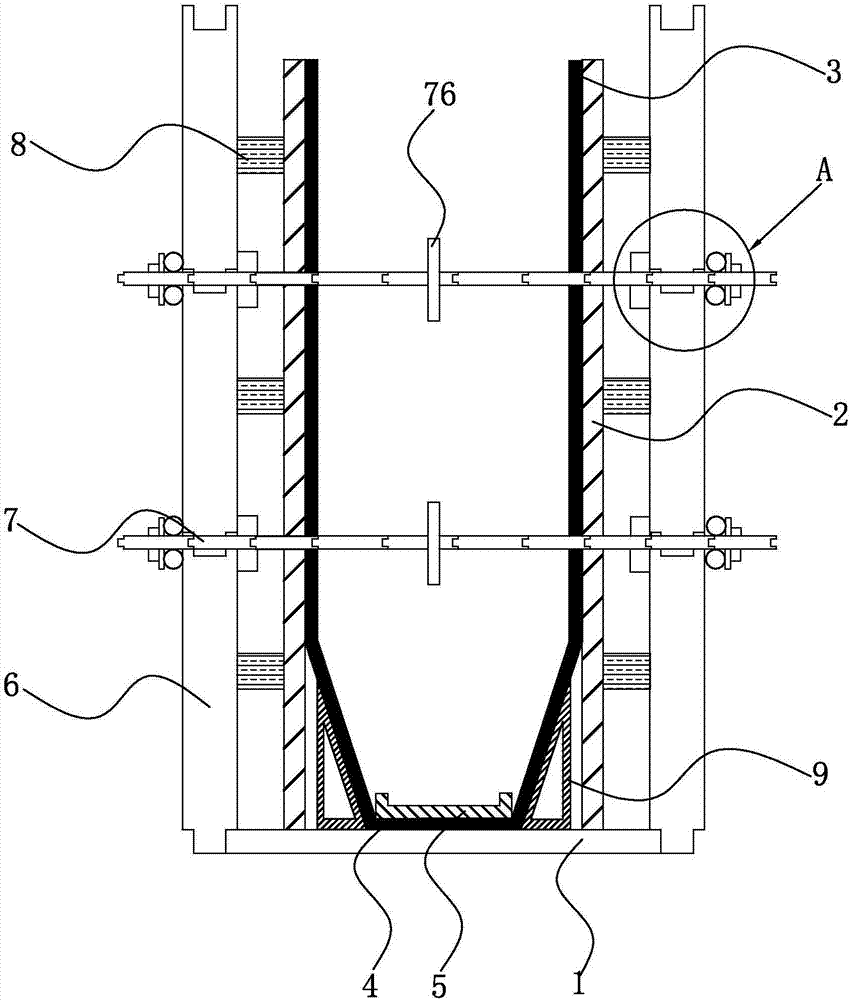

[0061] Embodiment two: a kind of caisson supporting structure, refer to figure 2 , The caisson support structure can be used repeatedly. A sleeper 1 is placed on the sand cushion, and a formwork is set up on the sleeper 1. The formwork is composed of a wooden board 2 and a blade foot formwork 3, and the blade foot formwork 3 is arranged in the wooden board 2; Shape setting, its bottom is provided with a flat part 4, the angle steel 5 is fixed on the inner side of the flat part 4, a spacer 9 is provided between the blade foot formwork 3 and the plank 2, and the spacer 9 is arranged outside the tapered part of the blade foot formwork 3; An iron frame 6 is installed outside the plank 2, and the iron frame 6 and the plank 2 are fixed by pull bolts 7, and a keel 8 is set between the iron frame 6 and the plank 2 to isolate.

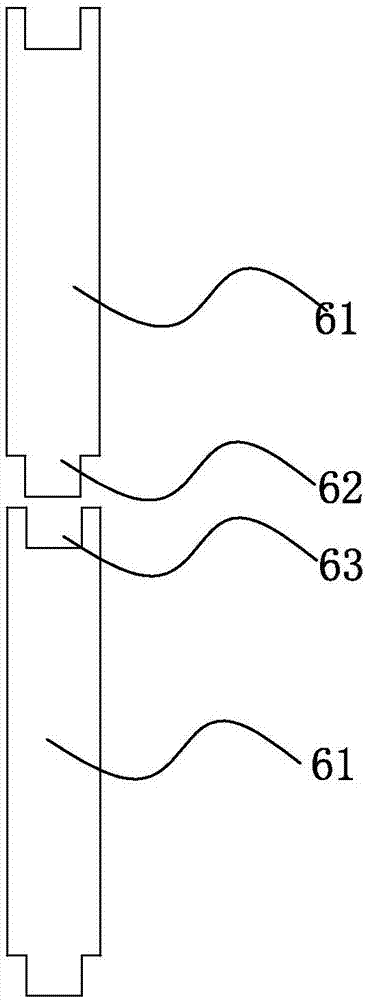

[0062] refer to image 3 , the iron frame 6 is separately arranged, and the iron frame 6 includes a plurality of iron frame units 61 plugged in to form, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com