Axial-liquid-feeding and tangent-liquid-discharging hydrodynamic retarder

A hydraulic retarder and liquid inlet technology, which is applied in the direction of liquid resistance brakes, brake types, brake actuators, etc., can solve the problems of complex geometry and processing technology of parts, high manufacturing costs, etc., to avoid fluctuations and improve The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

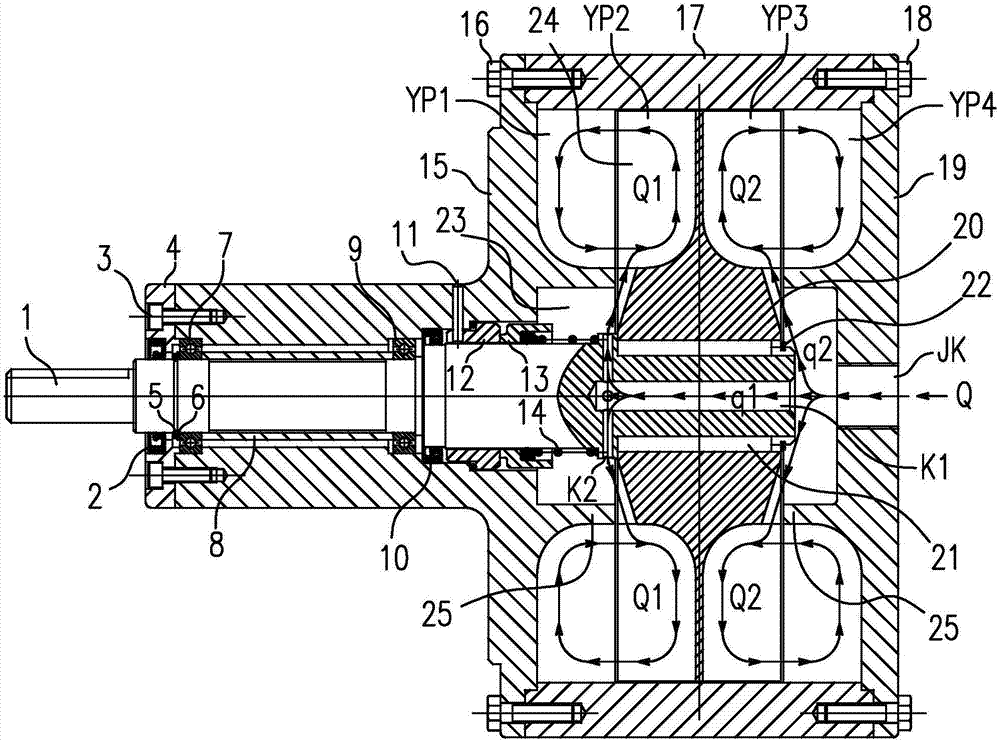

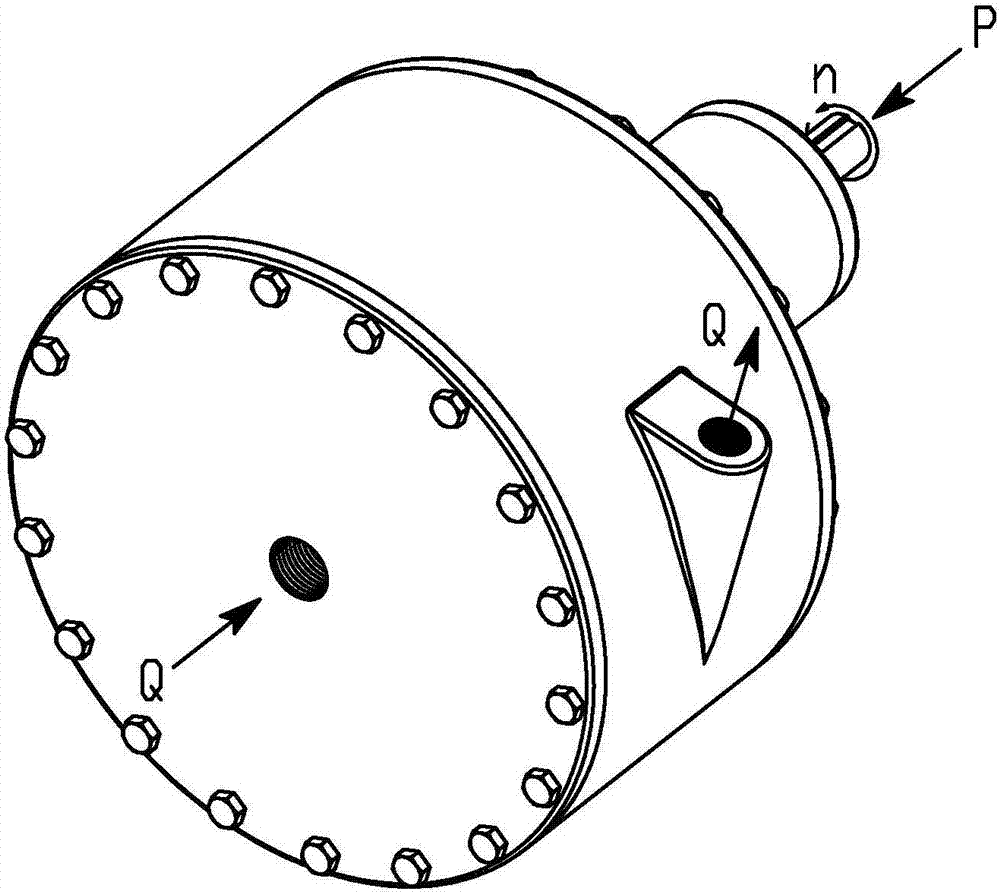

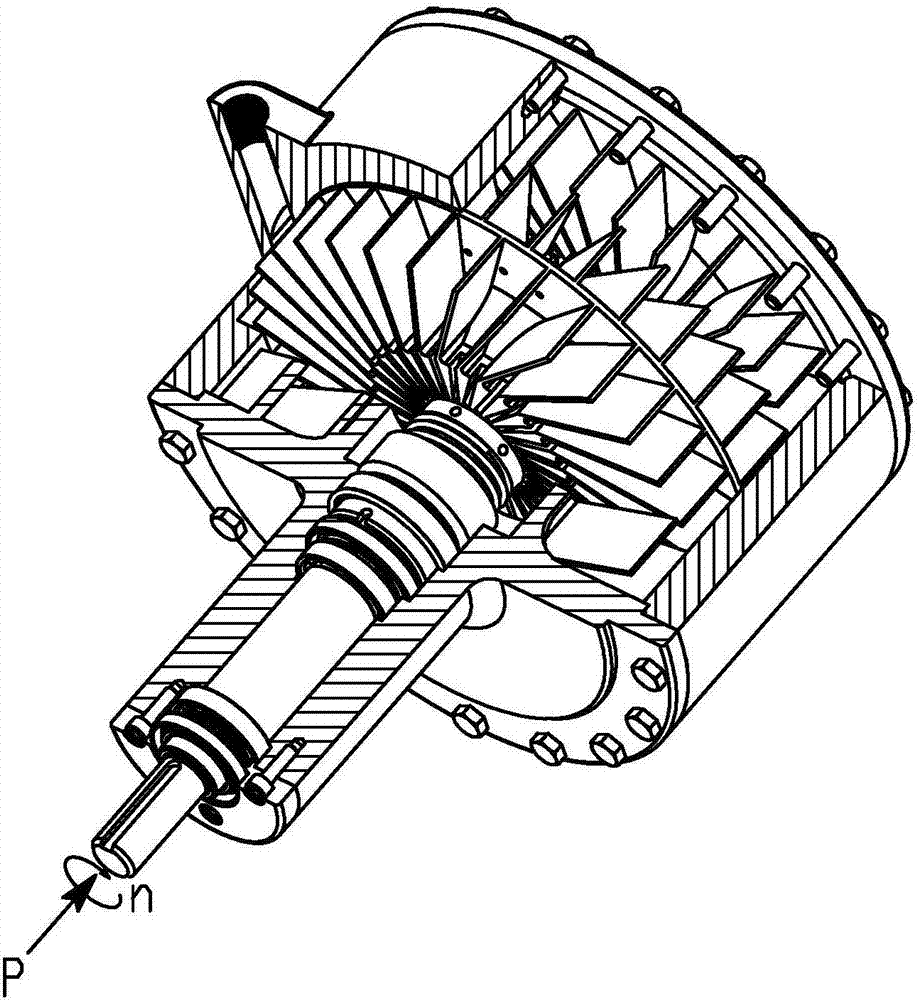

[0047] Example: a hydraulic retarder with axial liquid inlet and tangential liquid discharge

[0048] The retarder is integrally fixed on the vehicle body, and its transmission shaft 1 is connected to the vehicle wheels. After the retarder is started, the hydraulic resistance generated by the flow of its internal liquid flow forms a retarding braking effect on the wheels. The structure and working principle of the retarder in this embodiment will be described in detail below.

[0049] like Figure 1-Figure 4 As shown, the retarder is generally composed of a housing, a rotor and a stator, which are described as follows:

[0050] 1. Shell

[0051]In this embodiment, the housing is mainly composed of a liquid inlet cover 19 , a cylinder 17 , a bearing cover 15 and a gland 4 . The liquid inlet cover 19 is fixed on one end of the cylinder body 17 by a group of liquid inlet cover bolts 18, and the specific number of a group of liquid inlet cover bolts 18 is 16-30. The bearing en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com