Condensation type secondary heat exchanger

A heat exchanger, condensing technology, applied in the field of heat exchange, can solve the problems of poor heat exchange effect, high manufacturing cost, hot water pipe falling off, etc., to reduce heat loss, avoid secondary evaporation, and improve heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

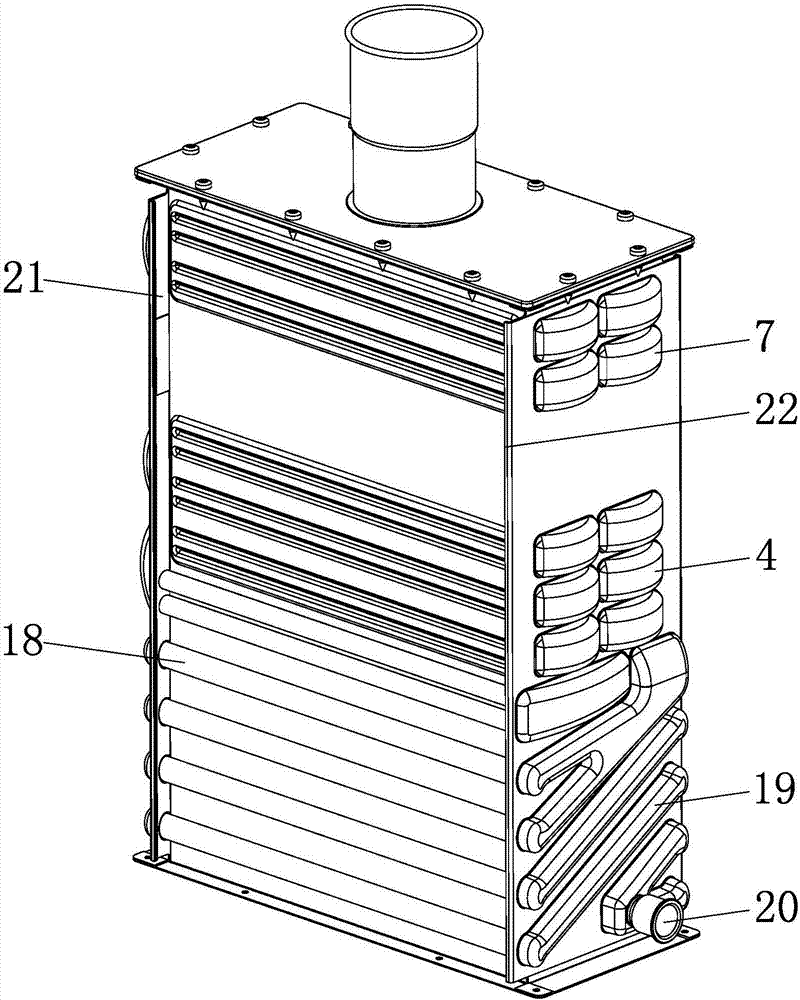

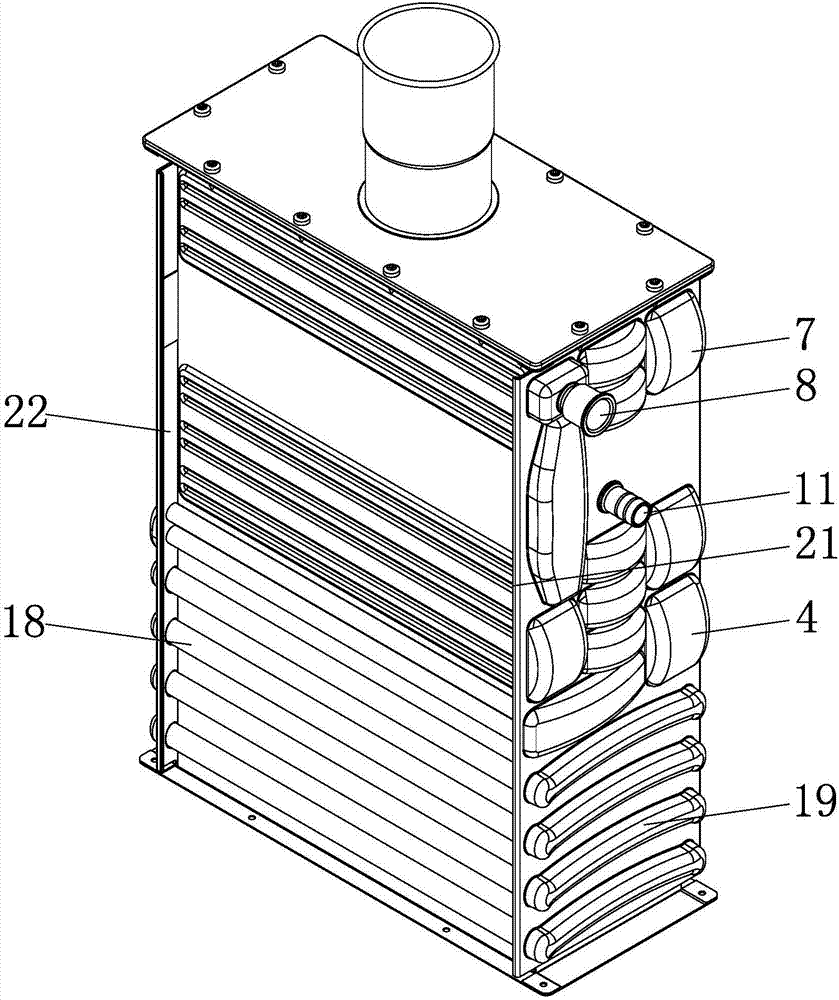

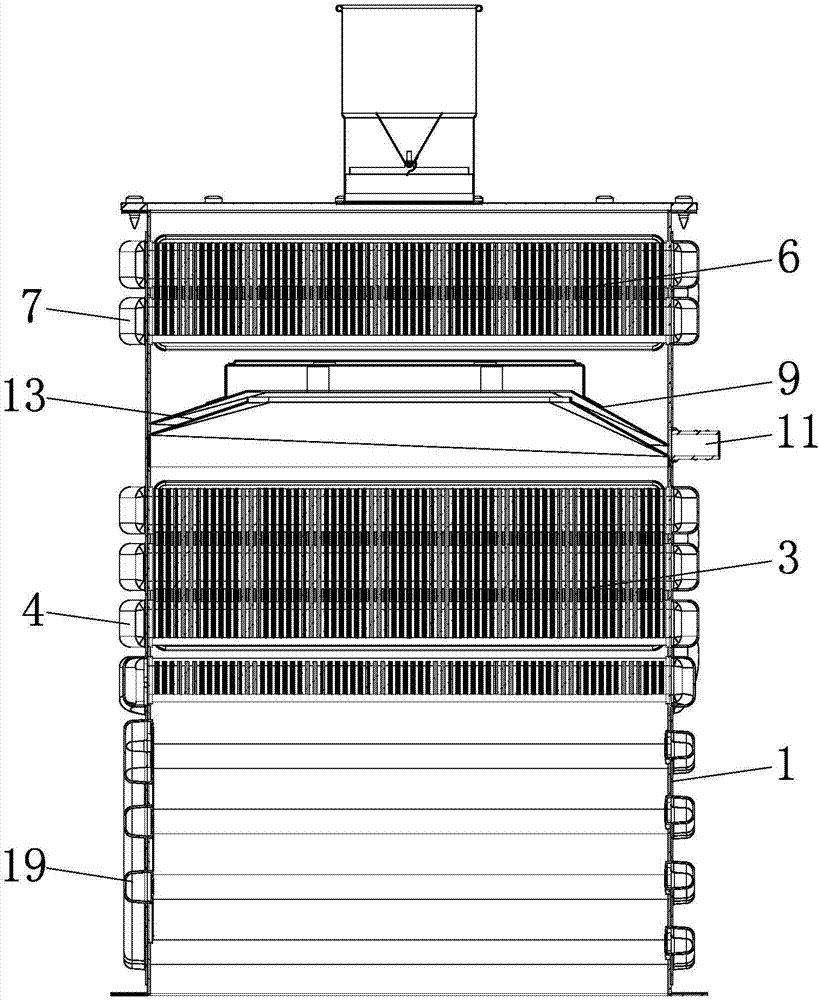

[0033] Such as figure 1 and figure 2The shown condensing secondary heat exchanger includes a cylindrical shell 1, and the interior of the shell 1 has a vertically arranged flue gas channel, such as image 3 with 4 As shown, the middle part of the flue gas passage is transversely provided with a number of parallel heat exchange tubes-2 and a heat absorber-3 sleeved on the number of heat exchange tubes-2, and the two ends of the number of heat exchange tubes-2 are respectively connected to the The outer wall of the housing 1 is flush, such as figure 1 with figure 2 As shown, the outer wall of the housing 1 has several water box covers 4 for connecting several heat exchange tubes 2 in series to form a series waterway 1, and the upper part of the flue gas channel is provided with a condensed water heat exchange structure, and the condensed water structure The outlet of the outlet is connected with the inlet of the series waterway one, and the flue gas channel is also provide...

Embodiment 2

[0048] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Image 6 with Figure 7 As shown, several heat exchange tubes surrounding the shell are arranged in parallel, that is, enter from the water inlet joint 8, then surround the shell surface in two ways, and finally connect together in parallel and discharge from the water outlet joint 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com