Hot rolling straightener supporting roller system roller surface curve optimization method

An optimization method and technology of backup rollers, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficulty, surface quality, dimensional accuracy requirements, and cracks, and improve the bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following will further explain and illustrate the method for optimizing the roll surface curve of the back-up roll system of the hot-rolled leveler according to the present invention in conjunction with the accompanying drawings and specific examples. However, the explanation and illustration do not constitute the technical solution of the present invention. Improperly qualified.

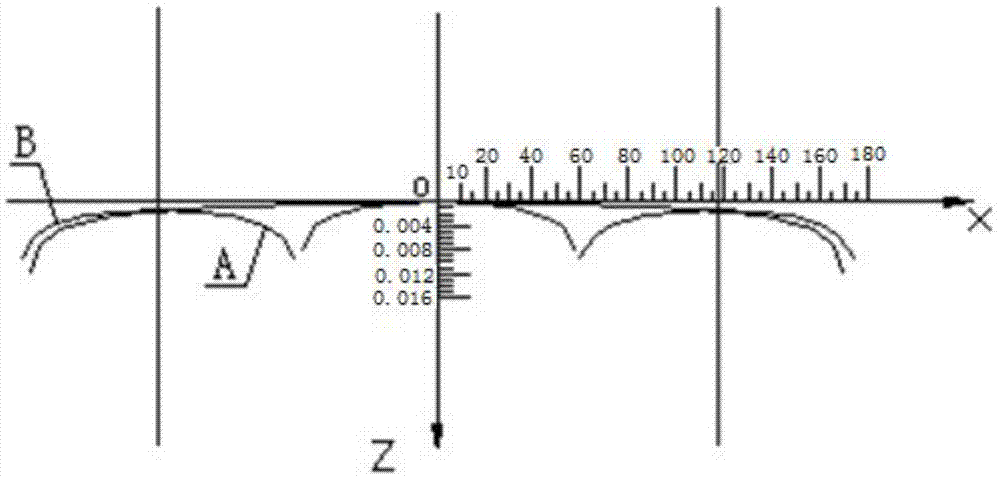

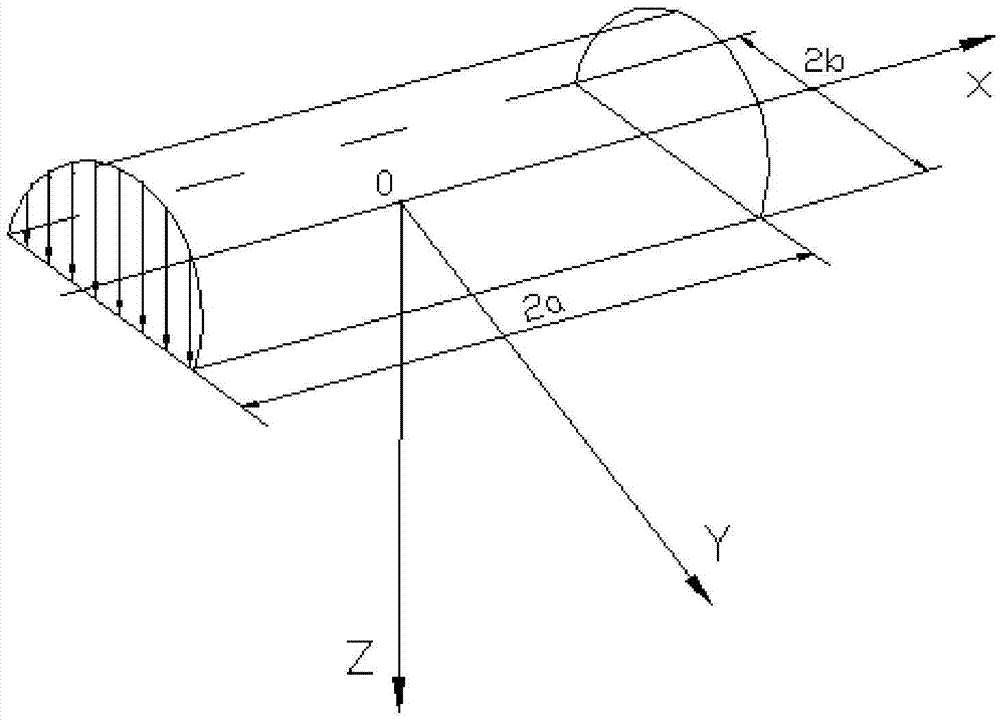

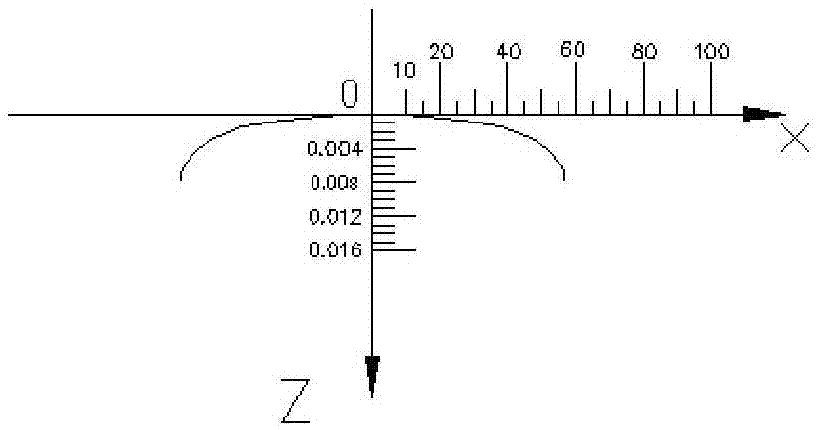

[0053] figure 1 It shows the shape of the prime line on the surface of the cylindrical roller when the finite-length roller is in direct contact with the elastic half-space, where the X-axis is the central axis in the length direction of the prime line on the surface (that is, the line contact force area), The origin is the center point O of the prime line on the surface (that is, the line contact force area), and the X-axis, Y-axis and Z-axis are perpendicular to each other.

[0054] Please refer to figure 1 , the model used in the method of optimizing the roll surface curve in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com