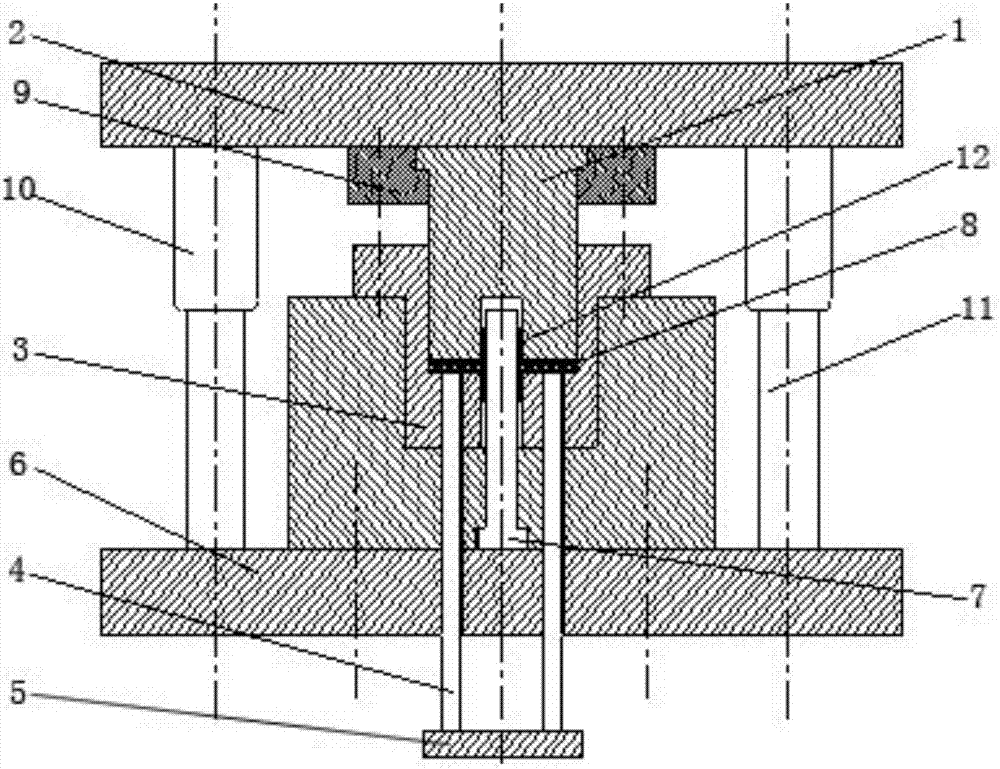

Inner bore double-face boss combined extrusion molding die and molding method

A composite extrusion and forming die technology, applied in metal extrusion die and other directions, can solve the problems affecting the safety and performance of welded parts, welding quality problems, affecting the appearance of products, etc., and achieve simple and reliable forming solutions and good surface quality. , the effect of simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] For an outer diameter D 1 40mm, inner diameter D 3 For a billet with a thickness of 15mm and a thickness t of 6mm, it is necessary to form a double-sided boss in the inner hole, and the outer diameter of the boss is D 2 20mm, the inner diameter of the boss and the inner diameter of the blank D 3 Equal to 15mm, height H is 8mm.

[0026] According to the principle of constant volume, the volume reduced in the direction of the thickness of the blank is equal to the sum of the volumes of the bosses: Extrusion stroke h=2H(D 2 2 -D 3 2 ) / (D 1 2 -D 3 2 ), according to the formula, the extrusion stroke h can be calculated as 2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com