Hearth-size-variable aluminum profile aging oven

A technology of aluminum profiles and aging furnaces, which is applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve problems such as poor temperature uniformity, inability to flexibly partition inner chamber space, and lower thermal efficiency, so as to ensure temperature uniformity and facilitate aging requirements. Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

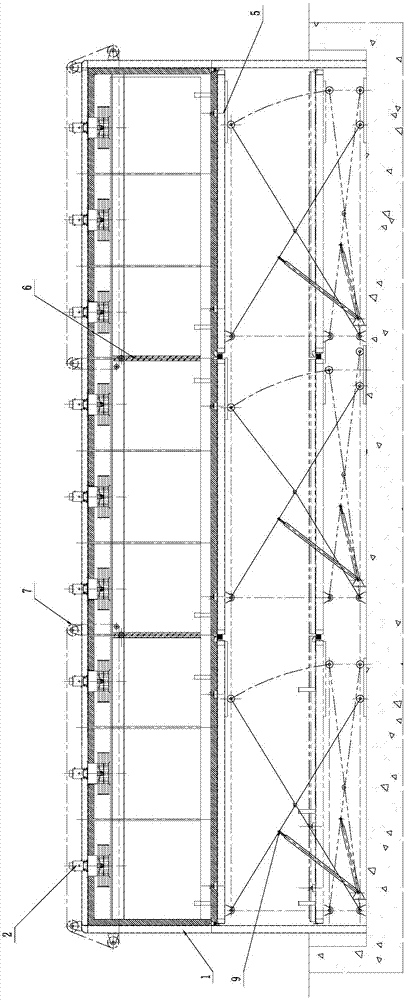

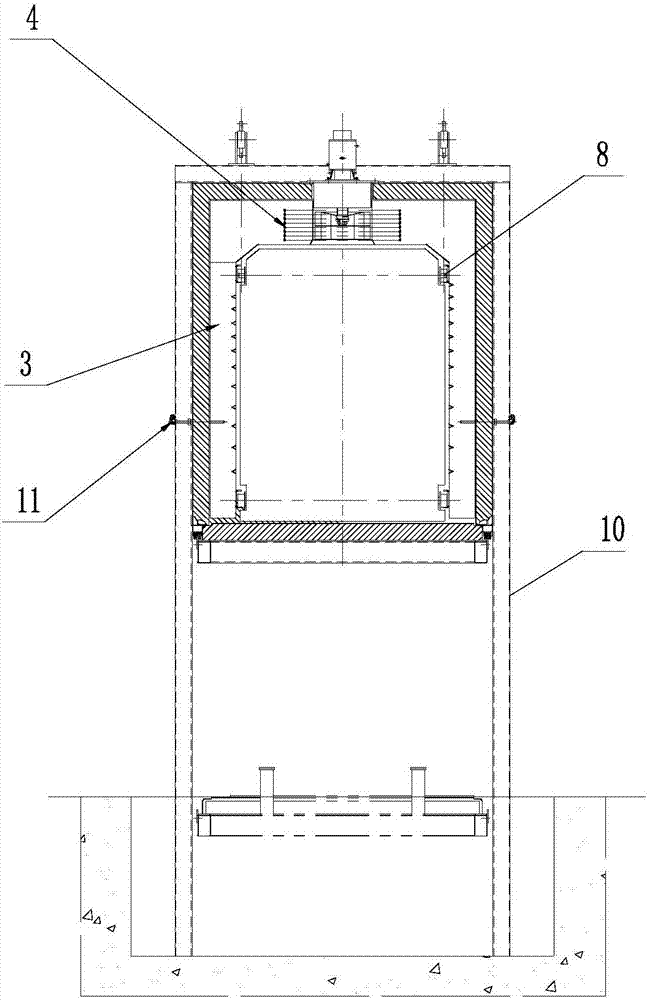

[0014] This embodiment is an aluminum profile aging furnace with a variable furnace size, the structure is as follows figure 1 and figure 2 As shown, it includes a furnace body 1, a circulating fan device 2, a diversion system 3, an electric heating system 4, and a furnace cover 5. The furnace body is a rectangular frame structure with a closed lower opening around it, and the furnace body is fixed and suspended on a steel frame 10. , the furnace body is welded by steel frame, thermal insulation cotton and stainless steel lining plates covering both sides of the thermal insulation cotton. Drive the furnace cover up and down, the furnace cover adopts a three-section structure, and each piece of furnace cover is driven by an independent lifting mechanism 9; the furnace body is equipped with a circulating fan device, a diversion system, an electric heating system and a temperature control device 11, and the circulation The fan device is installed on the top of the furnace body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com