Full-automatic steel bar forming device

A fully automatic and reinforced technology, which is applied in construction, building structure, and construction material processing, etc., can solve problems such as labor-intensive, low degree of automation, and increased construction costs, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and specific embodiments:

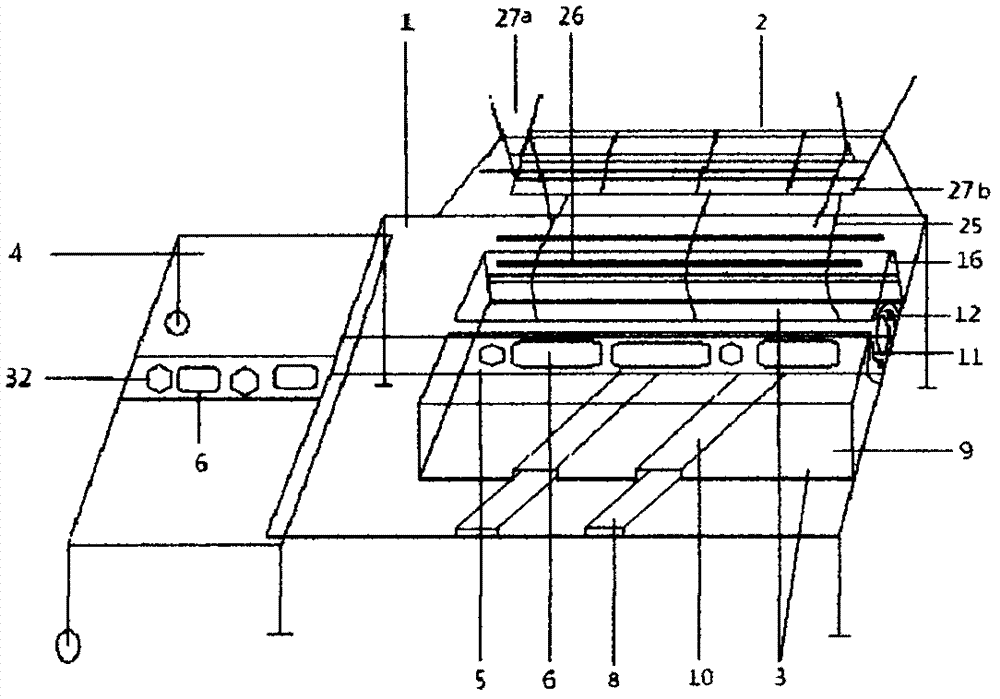

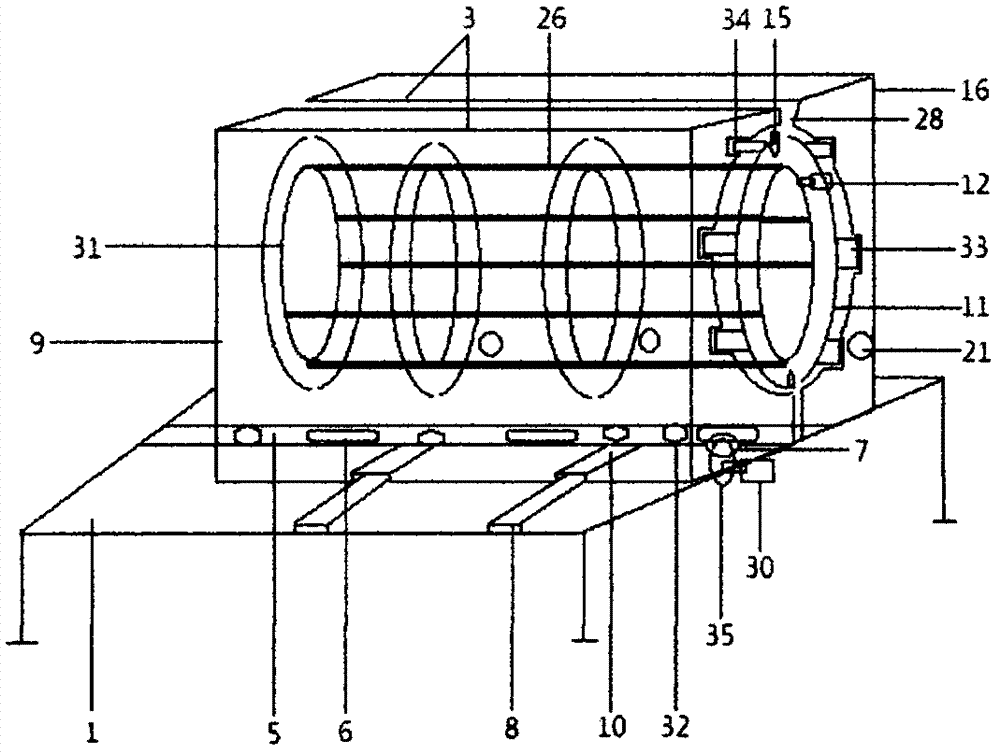

[0027] In specific implementation, such as Figure 1-Figure 5 According to the formula, the full-automatic steel bar tying equipment of the present invention includes a working table 1, a material support 2, and a steel bar tying device 3. One end of the working table is provided with a telescopic table 4, and a groove 5 is longitudinally provided on the working table. There are more than two strip rollers 6, the work surface under the strip rollers 6 is provided with more than two holes 7, and the work surface is transversely provided with two or more slide rails 8. The steel bar binding device 3 is divided into two types: movable and fixed. There are two parts. The bottom of the movable part 9 is provided with a sliding groove 10 opposite to the sliding rail 8. There are two or more arc-shaped rings 11 in the steel bar binding device 3, and two or more mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com