Device for transporting objects

An article, ball roller technology, applied in the direction of linear motion bearings, manufacturing tools, mechanical equipment, etc., can solve the problems of inconspicuous marking, error-prone marking system, correctly meeting the marking and therefore difficult to correct position, etc. achieve the effect of easy orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

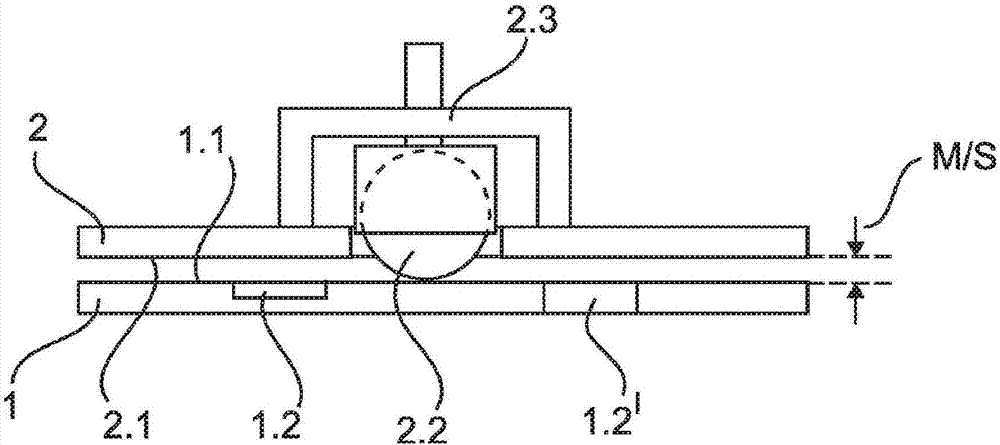

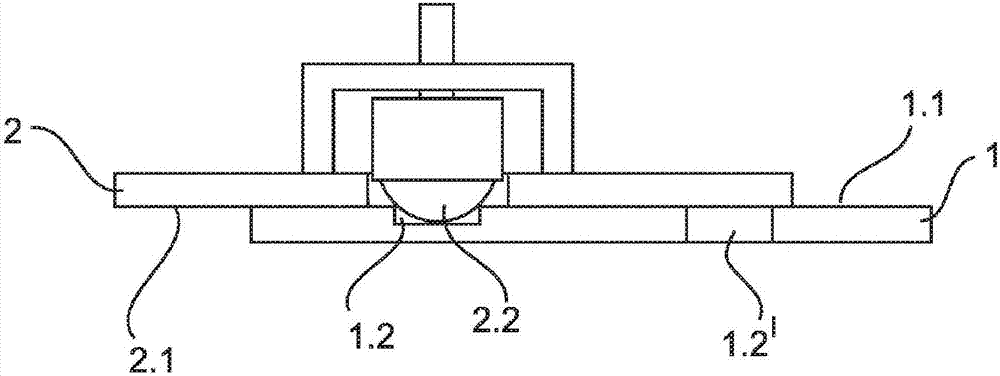

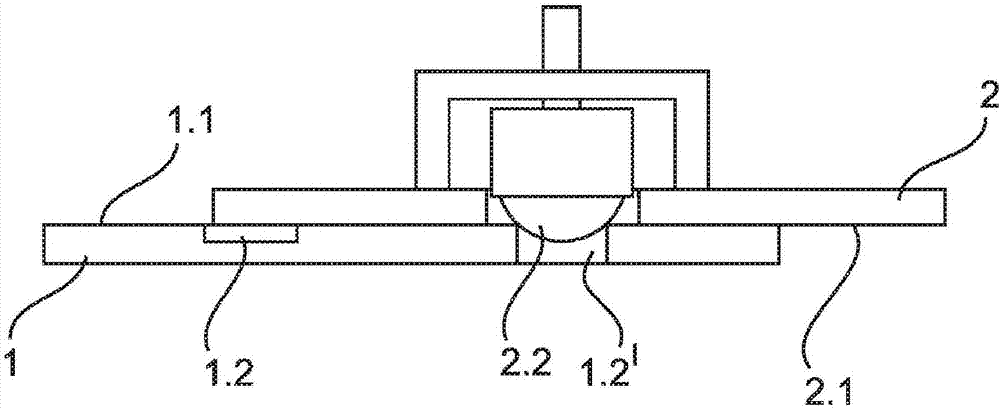

[0042] figure 1 A schematic diagram of a device according to the invention is shown. The device consists of a first structure 1 and a second structure 2 . The two structures 1 , 2 are each configured as a metal plate and are arranged parallel to one another. Here, the first structure 1 is arranged below the second structure 2 and serves as a base for the device. The second structure 2 is arranged above the first structure 1 . However, the device can also be used rotated by 180°, so that the first structure 1 is arranged above the second structure 2 .

[0043] The top of the first structure 1 is configured as a working surface 1.1 ( supporting surface) and facing the second structure 2. The underside of the second structure 2 is formed as a contact surface 2 . 1 and faces the first structure 1 . The working surface 1.1 and the contact surface 2.1 are oriented parallel and form a gap S here.

[0044] The gap S between the running surface 1.1 and the contact surface 2.1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com