High-temperature lubricant for use in the food industry

A food and high temperature technology, applied in the petroleum industry, lubricating compositions, thickeners, etc., can solve the problems of unsatisfactory and unsatisfactory residue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 7

[0079] Preparation of the high temperature oil according to the invention for the food industry

[0080] The two trimellitates are preset in a stirred boiler. At 100° C., polyisobutene and optionally another oil are added thereto under stirring. Subsequently, the mixture was stirred for 1 h in order to obtain a homogeneous mixture. The antiwear additive and antioxidant were added to the boiler at 60°C with stirring. After about 1 hour, the finished oil can be filled into the provided containers.

[0081] Composition of high temperature oil:

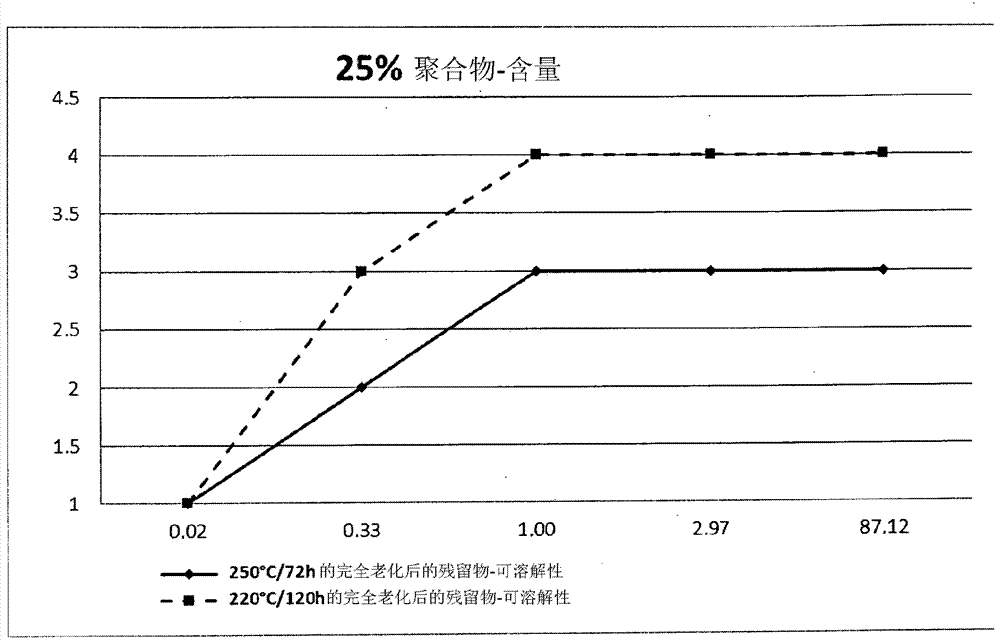

[0082] Table 1 shows the composition of the high temperature oil and the resolubility of the oil residue after complete evaporation of the oil as a function of the added amount of polyisobutene.

[0083] Table 1

[0084]

[0085]4 = very well soluble residue after complete evaporation, 3 = well soluble residue after complete evaporation, 2 = partially soluble residue after complete evaporation, 1 = insoluble residue after complete...

Embodiment 8 to 10

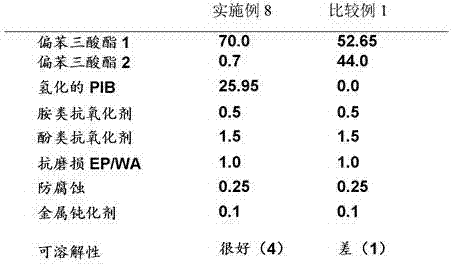

[0090] Oil composition (all data expressed in weight percent)

[0091] Table 2

[0092]

[0093] table 3

[0094]

[0095] Table 4

[0096] Example 10 Comparative example 3 trimellitate 1 0.0 52.65 trimellitate 2 0.0 44.0 long chain ester 1 40.4 0.0 Long chain ester 2 23.25 0.0 Hydrogenated PIB 33.00 0.0 Amine Antioxidants 0.5 0.5 Phenolic Antioxidants 1.5 1.5 Anti-wear EP / WA 1.0 1.0 anti-corrosion 0.25 0.25 metal deactivator 0.1 0.1 Solubility very good (4) Poor (1)

[0097] Food compatible high temperature fats according to the invention are exemplarily described in Table 5 below.

[0098] table 5

[0099] Example 11 Example 12 Example 13 Example 14 Example 15 Example 16 trimellitate 1 46.3 0.0 46.3 39.0 46.3 46.3 trimellitate 2 17.1 0.0 17.1 20.0 17.7 17.7 long chain ester 1 0.0 38.4 0.0 0.0 0.0 0.0 Long chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com